Fume denitration composite catalyst using titanium-base ceramics as carrier and preparation method thereof

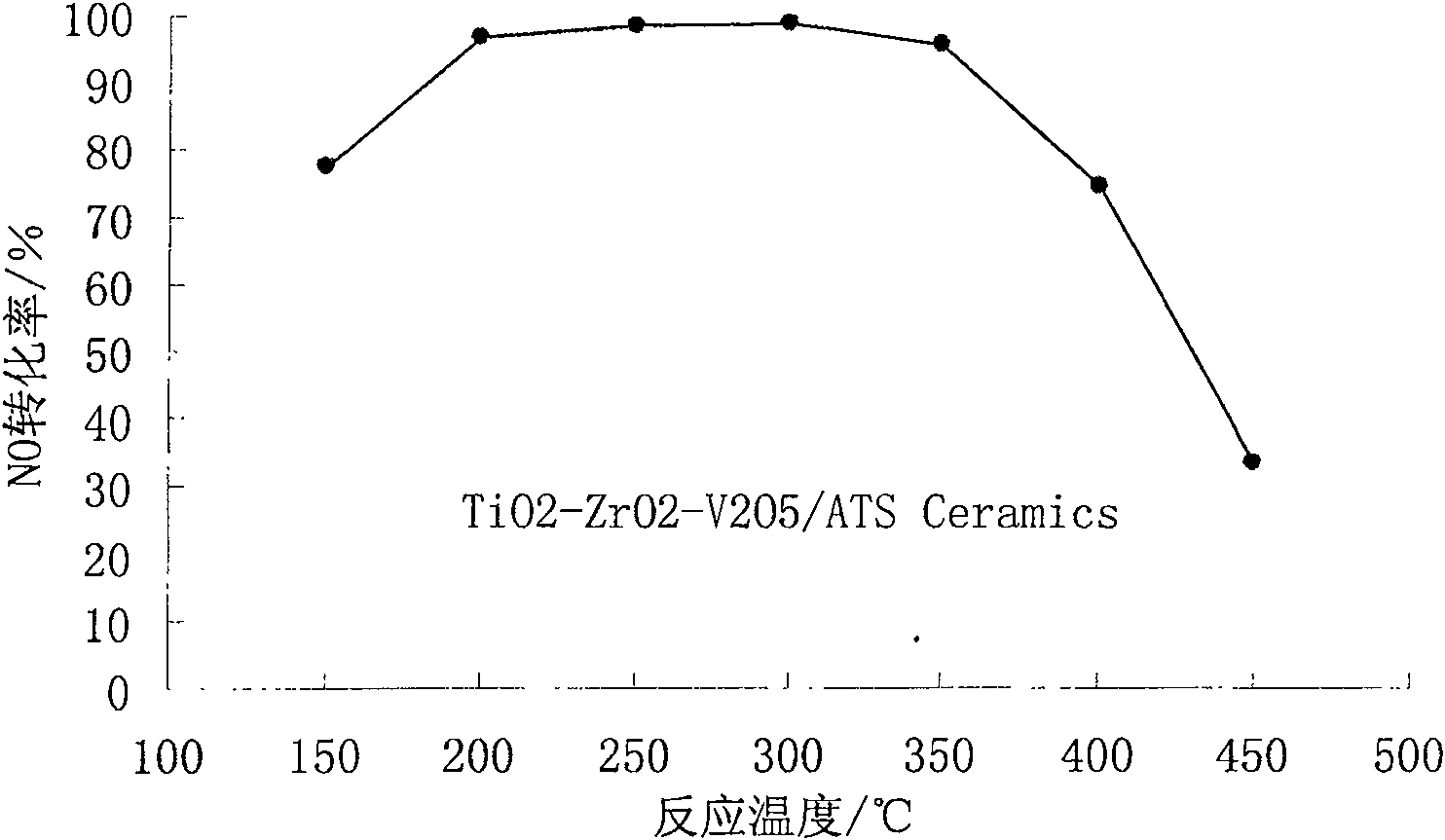

A catalyst, titanium-based technology, used in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of easy pulverization of catalysts and poor wear resistance, and achieve good thermal stability and water vapor resistance. The effect of strong, wide and long active temperature windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

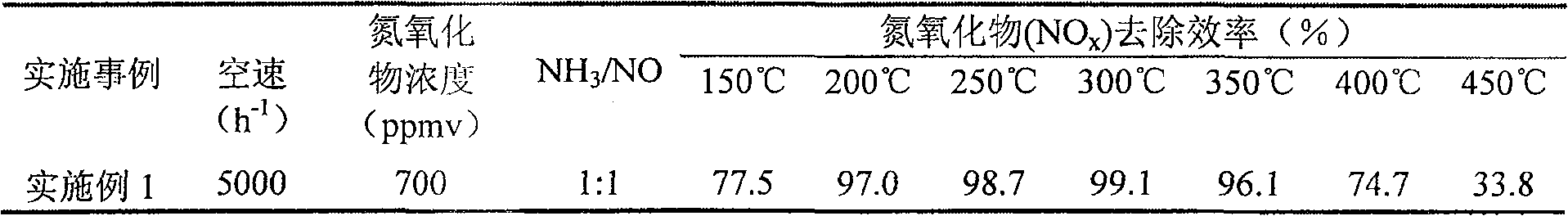

Embodiment 1

[0019] (1) TiO 2 -ZrO 2 -V 2 o 5 Composite sol preparation

[0020] First, stir 17ml butyl titanate and 25ml absolute ethanol to prepare liquid A, then add 12ml glacial acetic acid, 5ml water, and 30ml absolute ethanol in order to prepare liquid B, then add all liquid A to liquid B dropwise , stirred for 20 minutes, then added 5.3 g of zirconium oxychloride and stirred for 40 minutes to obtain a titanium-zirconium mixed sol. Then, ammonium metavanadate and oxalic acid were weighed in a molar ratio of 1:1 to weigh 1.9458g ammonium metavanadate and 2.0970g oxalic acid for batching, add distilled water and stir until the two are completely dissolved to prepare a vanadium solution, and finally add all the vanadium solution to the titanium In the zirconium composite sol, mix and stir for 20 to 60 minutes to obtain an orange-yellow titanium-zirconium-vanadium mixed sol.

[0021] (2) TiO 2 -ZrO 2 -V 2 o 5 Loading of composite oxide active coating

[0022] The acid-treated A...

Embodiment 2

[0025] (1) TiO 2 -ZrO 2 -V 2 o 5 Composite sol preparation

[0026] First, stir 17ml butyl titanate and 34ml absolute ethanol to prepare liquid A, then add 10ml glacial acetic acid, 5ml water, and 30ml absolute ethanol in order to prepare liquid B, then add all liquid A to liquid B dropwise , stirred for 20 minutes, then added 15.9 g of zirconium oxychloride and stirred for 40 minutes to obtain a titanium-zirconium mixed sol. Then, ammonium metavanadate and oxalic acid were weighed in a molar ratio of 1:1 to weigh 1.9458g ammonium metavanadate and 2.0970g oxalic acid for batching, add distilled water and stir until the two are completely dissolved to prepare a vanadium solution, and finally add all the vanadium solution to the titanium In the zirconium composite sol, mix and stir for 20 to 60 minutes to obtain an orange-yellow titanium-zirconium-vanadium mixed sol.

[0027](2)TiO 2 -ZrO 2 -V 2 o 5 Loading of composite oxide active coating

[0028] Immerse the acid-tr...

Embodiment 3

[0030] (1) TiO 2 -ZrO 2 -V 2 o 5 Composite sol preparation

[0031] First, mix 17ml of butyl titanate and 17ml of absolute ethanol to prepare liquid A, then add 15ml of glacial acetic acid, 10ml of water, and 36ml of absolute ethanol in order to prepare liquid B, then add all of liquid A to liquid B dropwise , stirred for 20 minutes, then added 1.8 g of zirconium oxychloride and stirred for 40 minutes to obtain a titanium-zirconium mixed sol. Then, ammonium metavanadate and oxalic acid were weighed in a molar ratio of 1:1 to weigh 1.9458g ammonium metavanadate and 2.0970g oxalic acid for batching, add distilled water and stir until the two are completely dissolved to prepare a vanadium solution, and finally add all the vanadium solution to the titanium In the zirconium composite sol, mix and stir for 20 to 60 minutes to obtain an orange-yellow titanium-zirconium-vanadium mixed sol.

[0032] (2)TiO 2 -ZrO 2 -V 2 o 5 Loading of composite oxide active coating

[0033] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com