Assembled structure of large area array infrared detector on cold platform and assembled method thereof

An infrared detector and assembly structure technology, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of long cooling time and large heat capacity, and achieve convenient operation, reduce heat radiation, and reduce Effect of parasitic thermal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing in embodiment:

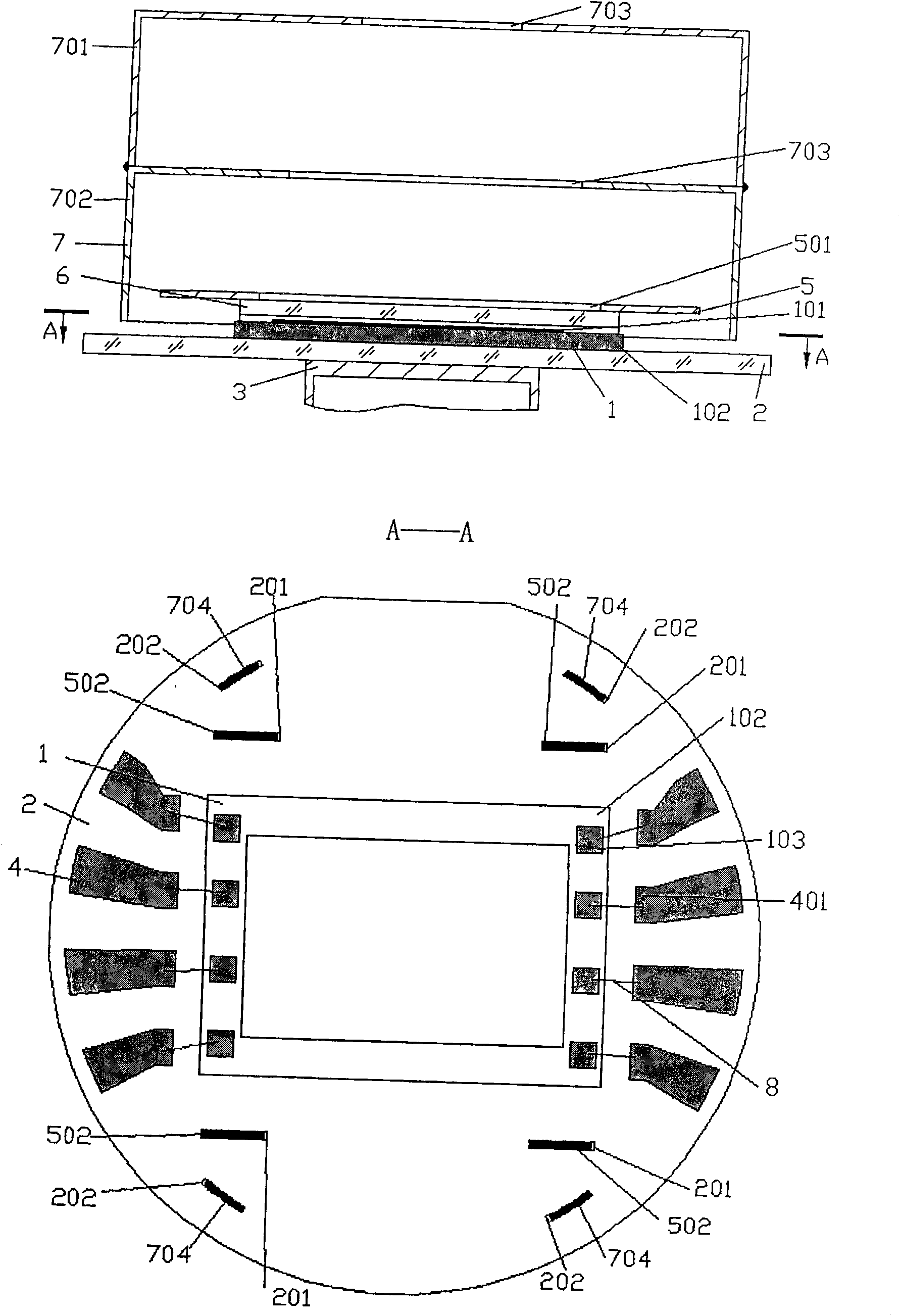

[0045] This embodiment is an assembly structure of a 320×240 area array infrared detector on a cold platform, as attached figure 1 As shown, its main implementation method is as follows:

[0046] (1) The photosensitive element 101 and the readout circuit module 102 are directly flip-bonded to form the infrared detector chip 1 . The circuit lead-out terminals 103 of the readout circuit 102 are arranged on both side edges of the readout circuit module 102 .

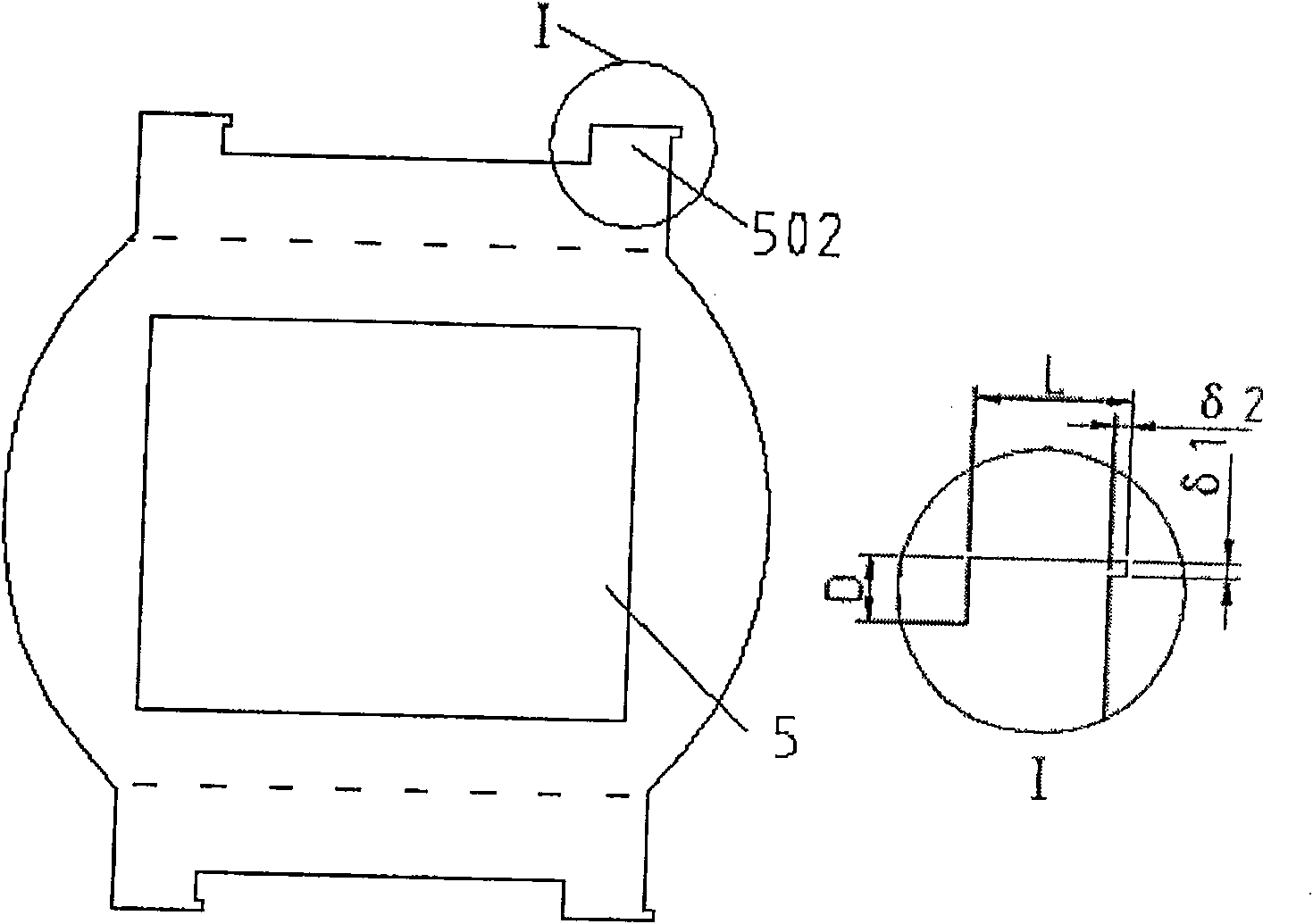

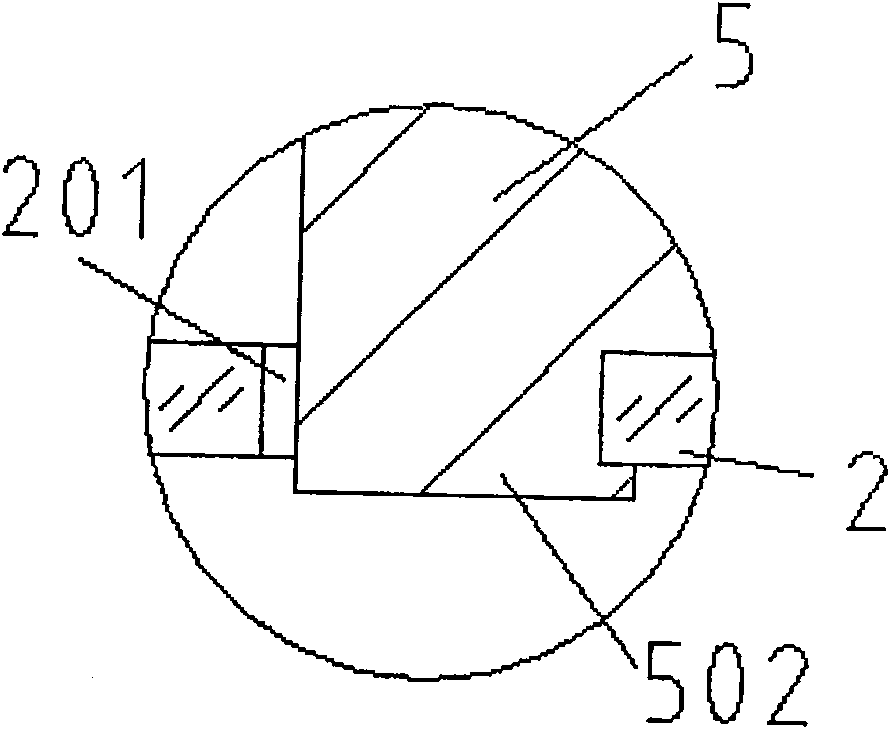

[0047] (2) Substrate The substrate 2 is a sapphire sheet with a thickness of ф21.7mm and a thickness of 0.6mm. On the ф21.7mm round gemstone after cleaning, ion-sputter a Cr film with a thickness of 300A, and then sputter Au to make the thickness of the metal layer reach 1μm, and then photoetch and corrode the designed lead circuit pattern on the gemstone. Lead circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com