Ferrite nanometer particle embedded antiferromagnetic oxide matrix composite material and preparation method

A nanoparticle and composite material technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve problems such as less research, achieve simple operation, easy chemical ratio, and achieve the effect of regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] CuFe with a sintering temperature of 900 °C was prepared according to the above method 2 o 4 Composite materials with nanoparticles embedded in CuO antiferromagnetic matrix. The first step is to weigh copper nitrate and iron nitrate according to the chemical molar ratio of antiferromagnetic oxide ions and iron ions at 100:1, wherein the copper nitrate is 0.03mol and the iron nitrate is 0.003mol, and they are mixed and dissolved in 300mL deionized In water, configure a mixed solution of metal ions with a copper ion concentration of 0.1mol / L; in the second step, weigh 0.07mol ammonium bicarbonate according to the stoichiometric ratio, dissolve it in 35mL deionized water, and configure a molar concentration of 2mol / L carbonic acid Aqueous solution of hydrogen ammonia, ammonia bicarbonate should be over 10%. Under continuous stirring, add the aqueous solution of ammonium bicarbonate to the above-mentioned mixed solution of metal ions, add 0.5mL ammonia water to adjust the ...

Embodiment 2

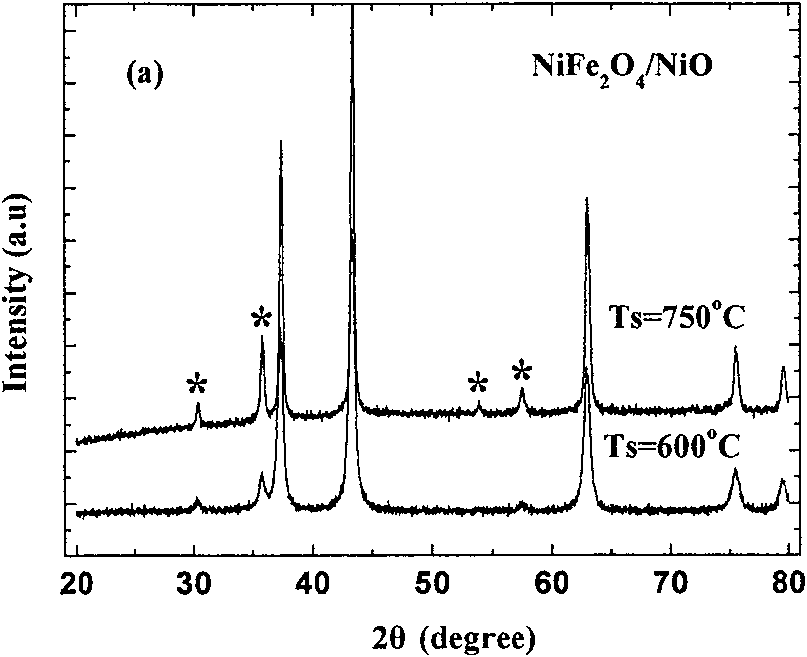

[0029] NiFe with a sintering temperature of 600 °C was prepared according to the above method 2 o 4 Composite materials with nanoparticles embedded in NiO antiferromagnetic matrix. In the first step, nickel nitrate and iron nitrate are weighed according to the chemical molar ratio of antiferromagnetic oxide ions and iron ions to be 10:1, wherein nickel nitrate is 0.03mol, iron nitrate is 0.003mol, mixed and dissolved in 300mL deionized In water, configure a metal ion mixed solution with a nickel ion concentration of 0.1mol / L; in the second step, weigh 0.07mol ammonium bicarbonate according to the stoichiometric ratio, dissolve it in 35mL deionized water, and configure a molar concentration of 2mol / L carbonic acid Aqueous solution of hydrogen ammonia, ammonia bicarbonate should be over 10%. Under continuous stirring, add the aqueous solution of ammonium bicarbonate to the above-mentioned mixed solution of metal ions, add 0.5mL ammonia water to adjust the pH=7, and form a preci...

Embodiment 3

[0031] NiFe with a sintering temperature of 700 °C was prepared according to the above method 2 o 4 Composite materials with nanoparticles embedded in NiO antiferromagnetic matrix. In the first step, nickel nitrate and iron nitrate are weighed according to the chemical molar ratio of antiferromagnetic oxide ions and iron ions at 1:2, wherein nickel nitrate is 0.03mol and iron nitrate is 0.003mol, and they are mixed and dissolved in 300mL deionized In water, configure a metal ion mixed solution with a nickel ion concentration of 0.4mol / L; in the second step, weigh 0.07mol ammonium bicarbonate according to the stoichiometric ratio, dissolve it in 35mL deionized water, and configure a molar concentration of 2mol / L carbonic acid Hydrogen ammonium aqueous solution, ammonia bicarbonate should be over 10%. Under continuous stirring, add the aqueous ammonium bicarbonate solution to the above metal ion mixed solution, add 0.5mL ammonia water to adjust the pH=7.5, and form a precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com