Multifunction nitration back nitration integrated auto dynamic film bioreactor

A technology of nitrification and denitrification and bioreactor, which is applied in the field of multifunctional nitrification and denitrification integrated self-generated dynamic membrane bioreactor, which can solve the problems of membrane pollution and expensive cost of membrane units, so as to improve the treatment level and biodegradability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

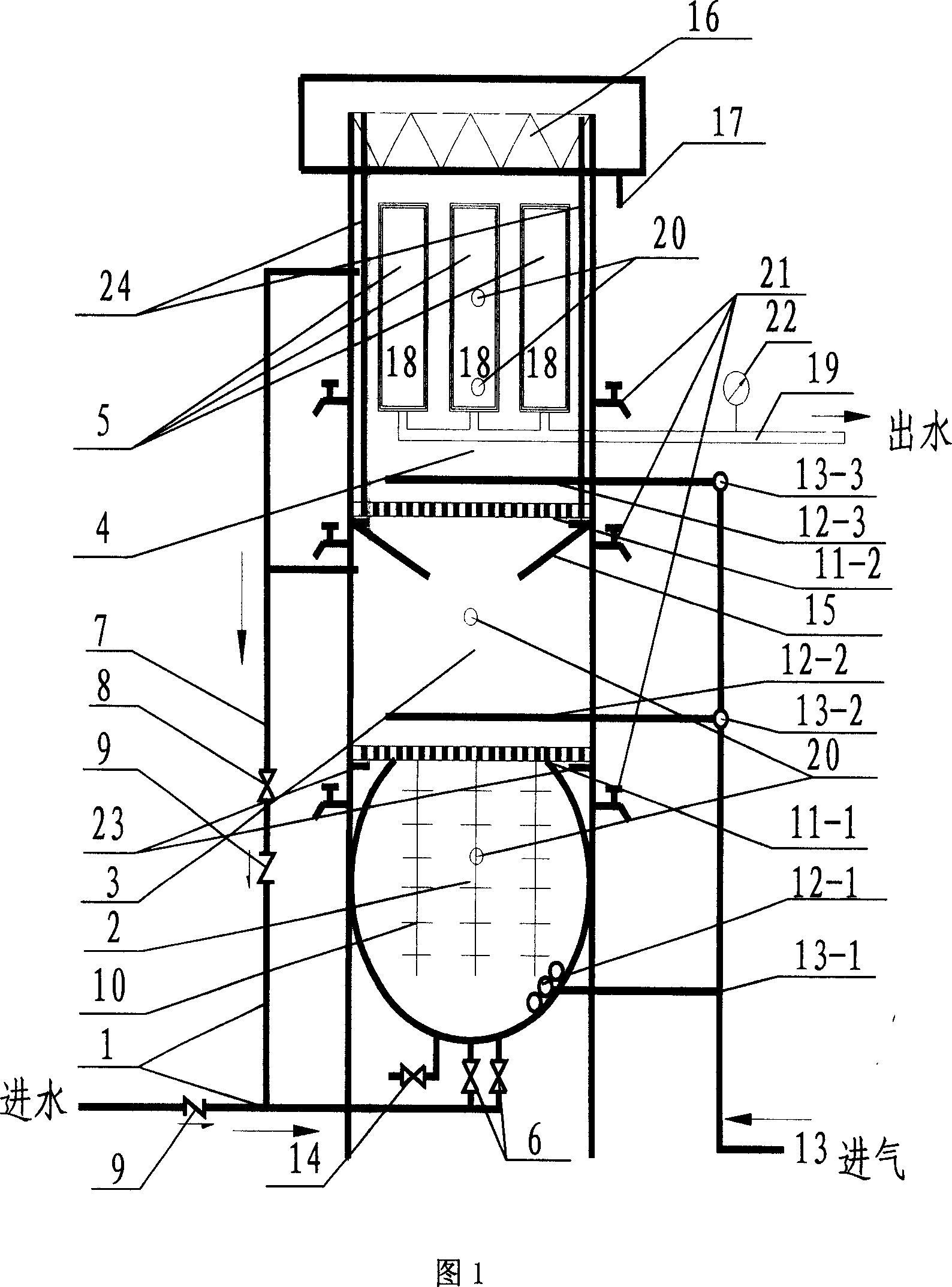

[0043] The multifunctional nitrification and denitrification integrated self-generated dynamic membrane bioreactor has a cylindrical structure, which is composed of a water inlet system 1, a pretreatment reaction area 2, an aeration reaction area 3, and a semi-aeration area 4 from bottom to top. As shown in Figure 1, the pretreatment reaction zone 2, the aeration reaction zone 3 and the semi-aeration zone 4 are all separated by perforated plates, which facilitate the passage of water, and at the same time support and define each functional zone. in:

[0044] The water inlet system 1 is composed of a water inlet 6 and a jet gravity return pipe 7. Both the water inlet pipe and the return pipe 7 are provided with a one-way valve 9 to avoid backflow of water in case of an accident. The use of the return pipe 7 depends on the reaction state of the pretreatment reaction zone. If the pretreatment reaction zone is anoxic reaction, it is used, and if the pretreatment reaction zone is a...

Embodiment 2

[0053] The reactor obtained in Example 1 was used to treat domestic sewage in a certain community.

[0054] The domestic sewage enters the multifunctional nitrification and denitrification integrated self-generated dynamic membrane bioreactor, and the airflow inside the reactor pushes the suspended packing into a flowing state, and the domestic sewage is decomposed under the action of the biofilm of the suspended packing in the pretreatment area. The hydraulic retention time in the pretreatment area is 1~2h, and the dissolved oxygen is 1~2mg / L; after entering the aeration reaction area, under the action of micro aeration, the sewage is further purified by activated sludge, and part of the denitrification is completed. The hydraulic retention time in the aerated reaction zone is 0.5h, and the dissolved oxygen is below 0.5mg / L; after that, it enters the semi-aerated reaction zone (the zone is anoxic at this time) for further denitrification, and the hydraulic retention time in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com