Infrared laser detecting and displaying dual-purpose luminescent film and preparation process thereof

A technology of infrared laser and light-emitting film, applied in the field of infrared laser detection, can solve the problem of low light-emitting brightness of light-emitting film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Transparent organic medium PVC resin 140g

[0026] Plasticizer Dibutyl phthalate 20g

[0027] Dioctyl phthalate 10g

[0028] Lubricant: Zinc Stearate 1.5g

[0029] Luminescent material NaYF 4 : Yb, Tm 50g

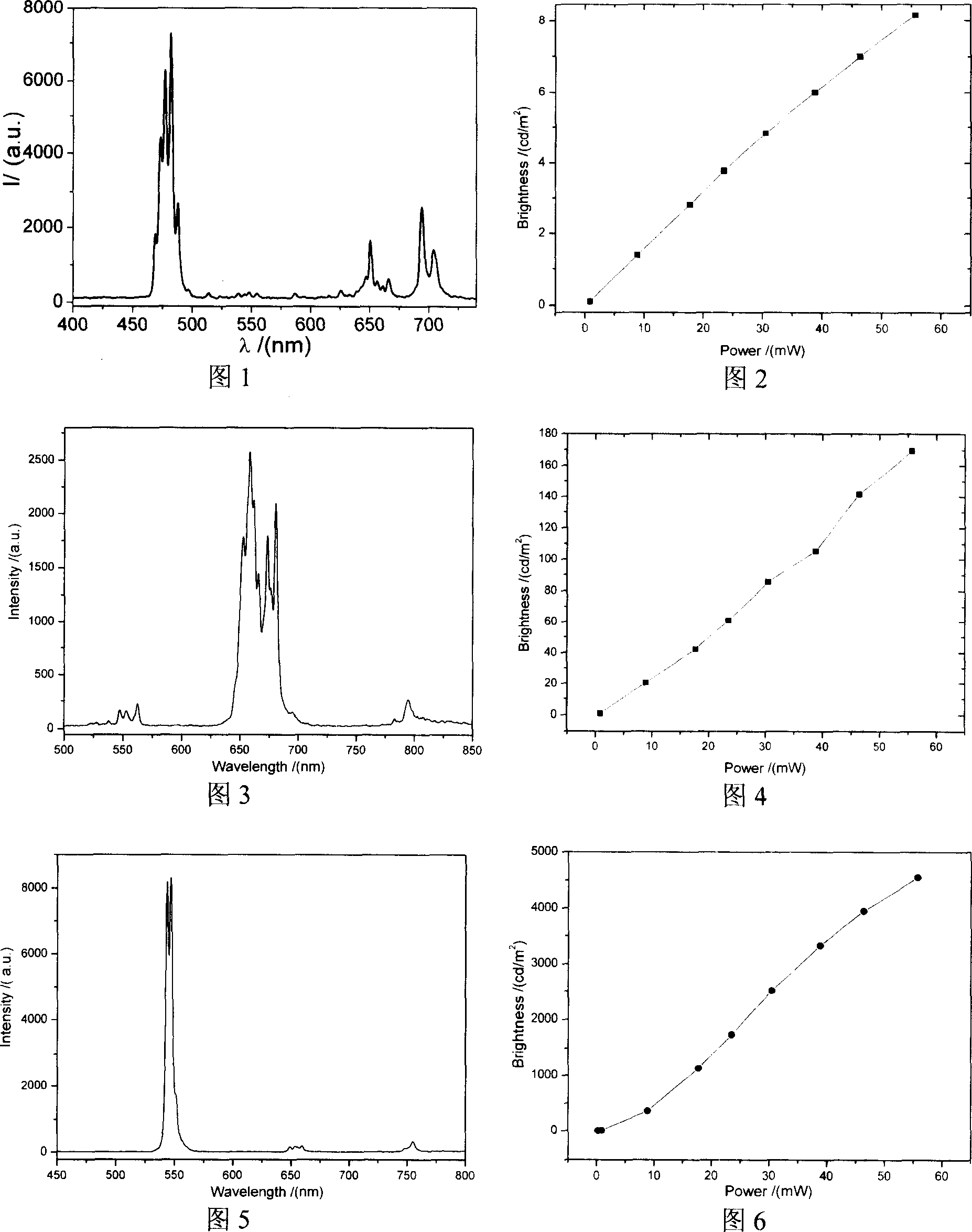

[0030] Weigh the raw materials according to the recipe, add other materials except the luminescent material into the high-speed mixer, disperse evenly at high speed, then add the luminescent material and stir evenly. The mixed raw material is made into a luminescent film with a thickness of 100 μm through a calendering process. The luminescent film emits blue light under the irradiation of a 980nm laser. Its luminous spectrum and luminous brightness are shown in Figures 1 and 2.

example 2

[0032] Transparent organic medium P440 100

[0033] Auxiliary DOP 60

[0034] ED1300 10

[0035] Sn102 3

[0036] Luminescent material Y 2 o 3 : Yb, Er

[0037] Put DOP, ED 1300, and Sn102 into the container, stir at 200N / min for 2min, then put in P440 resin, stir at 600~700N / min for 5min, and prepare a blank paste. Weigh the luminescent material and the blank paste according to the content of 40%, stir for 3 minutes at a speed of 600~700N / min, mix well, and let it stand naturally for 30 minutes to defoam. The white PET film is used as the substrate, and the 400um QTG film applicator is used to coat the film. The film coating speed is 35mm / s~60mm / s, the curing temperature is 165~170℃, and the time is 2 minutes. The luminescent film emits red light under the irradiation of a 980nm laser. Its luminous spectrum and luminous brightness are shown in Figures 3 and 4.

example 3

[0039] Transparent organic medium Modified acrylic resin 70

[0040] Flux slow drying agent 6

[0041] Luminescent material Y 2 o 2 S: Yb, Ho 30

[0042] Add the liquid raw materials in the formula into the container, stir evenly, add the luminescent material under the stirring condition, and prepare the ink. Clean the base material of the aluminum plate, print the ink evenly on the aluminum plate with a 200-mesh screen, and print 3 times to obtain a luminescent film of 100 μm, and then dry it. The luminescent film emits green light under the irradiation of a 980nm laser. Its luminous spectrum and luminous brightness are shown in Figures 5 and 6. The luminescent film emits green light under the irradiation of a 1060nm laser. Its light-emitting photos are shown in Figure 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com