Mfg. method of braking band of integral pressed blending fibre

A technology of integrally pressing and blending fibers, which is applied in brake parts, textiles and papermaking, etc. It can solve the problems of unstable quality, high price of finished products, easy fiber clumping, etc., and achieve good fiber mixing effect, stable quality of finished products, resin evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

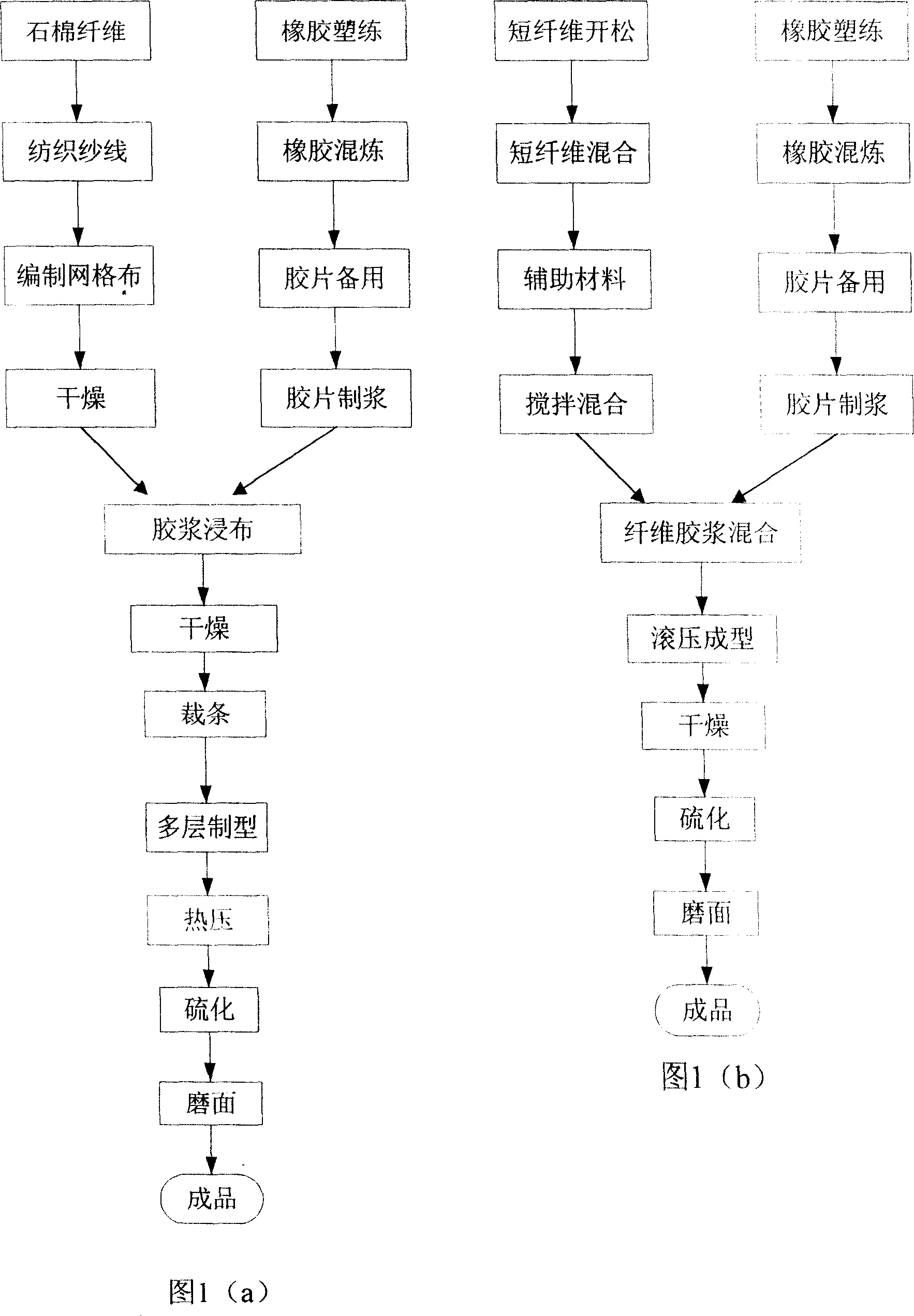

Problems solved by technology

Method used

Image

Examples

Embodiment 1

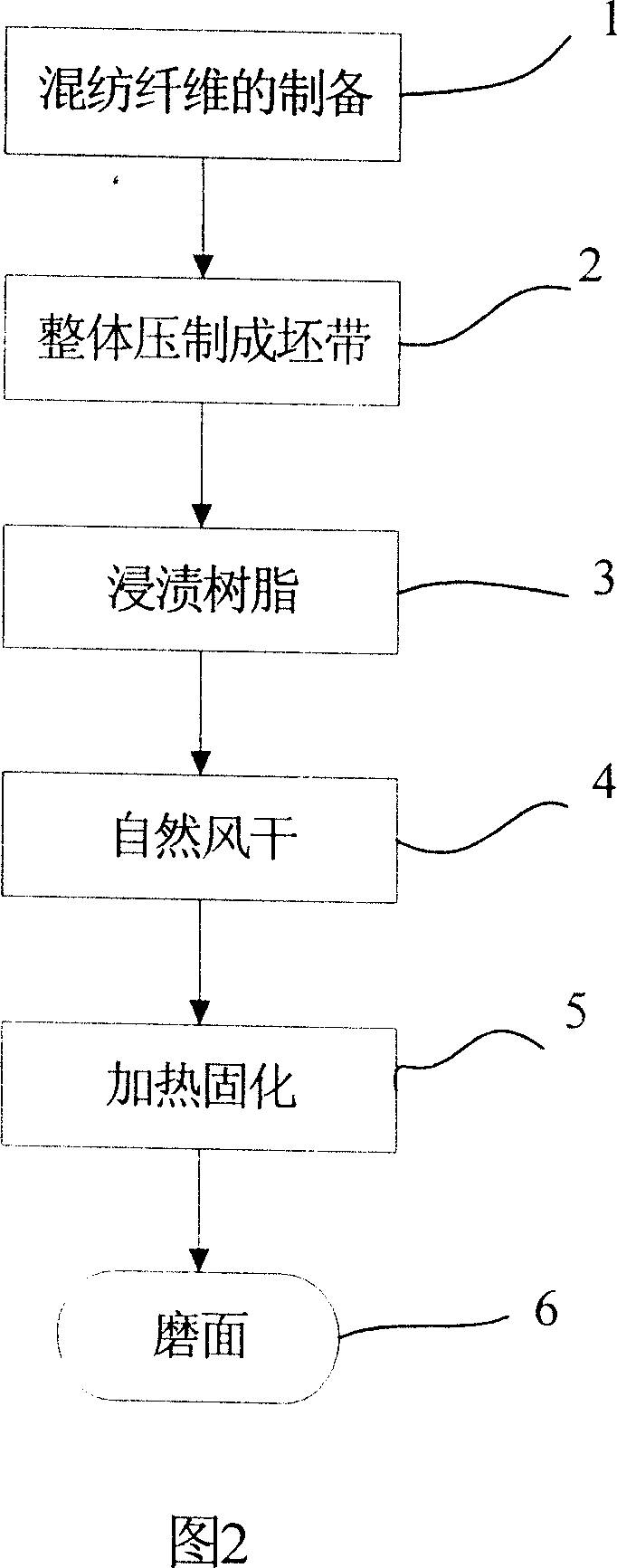

[0030] A method for manufacturing a brake belt integrally pressed by blended fibers, which is formed by blending various friction material fibers and adding metal mesh to form a blank belt as a whole, and using phenolic resin as an adhesive material, which is specifically carried out in accordance with the following steps:

[0031] Step 1: Preparation of blended fibers, use an opener to open various friction material fibers, and then use a blending machine to blend various friction material fibers, the various friction material fibers are acrylic fibers, aramid fibers , Glass fiber, blended with carbon fiber;

[0032] Step 2: The whole is pressed into a blank belt, and a variety of friction material fibers that have been blended are mixed for a second time with a carding machine, and carded into a velvet strip-shaped semi-finished product with a thickness of 1.5cm, and a layer of copper with a diameter of 0.1mm is added. Wire mesh, and then according to the sequence of one lay...

Embodiment 2

[0038] A method for manufacturing a brake belt integrally pressed by blended fibers, which is formed by blending various friction material fibers and adding metal mesh to form a blank belt as a whole, and using phenolic resin as an adhesive material, which is specifically carried out in accordance with the following steps:

[0039] Step 1: Preparation of blended fibers, use an opener to open various friction material fibers, and then use a blending machine to blend various friction material fibers, the various friction material fibers are acrylic fibers, aramid fibers , Glass fiber, blended with carbon fiber and hemp fiber;

[0040] Step 2: The whole is pressed into a blank belt, and a variety of friction material fibers that have been blended are mixed for a second time with a carding machine, and carded into a velvet strip-shaped semi-finished product with a thickness of 2.0cm, and a layer of aluminum with a diameter of 0.2mm is added. Alloy wire mesh, and then according to ...

Embodiment 3

[0046] A method for manufacturing a brake belt integrally pressed by blended fibers, which is formed by blending various friction material fibers and adding metal mesh to form a blank belt as a whole, and using phenolic resin as an adhesive material, which is specifically carried out in accordance with the following steps:

[0047] Step 1: Preparation of blended fibers, use an opener to open various friction material fibers, and then use a blending machine to blend various friction material fibers, the various friction material fibers are acrylic fibers, aramid fibers , glass fiber, or blended with carbon fiber, cellulose fiber, and hemp fiber;

[0048]Step 2: The whole is pressed into a blank belt, and a variety of friction material fibers that have been blended are mixed for a second time with a carding machine, and carded into a velvet strip-shaped semi-finished product with a thickness of 1.5cm, and a layer of copper with a diameter of 0.15mm is added. Wire mesh, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com