Method and device for recoverying and using afterheat of furnace quench belt of ceramic production line

A waste heat recovery and production line technology, applied in ceramic material production, furnace, waste heat treatment, etc., can solve the problems of uneven droplet size, uneven powder particle size, and low powder output, etc., which is conducive to popularization and energy consumption. The effect of reducing and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

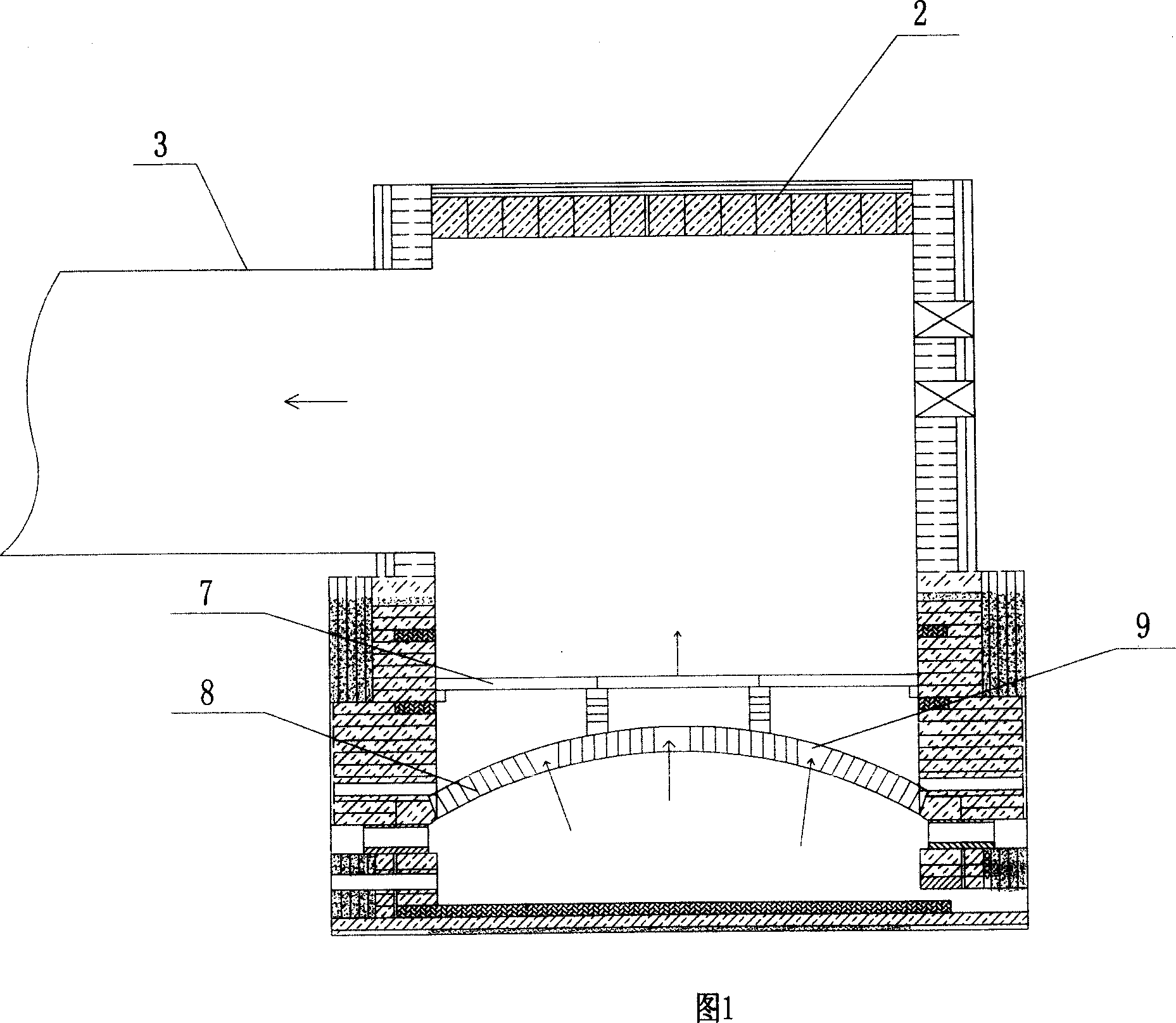

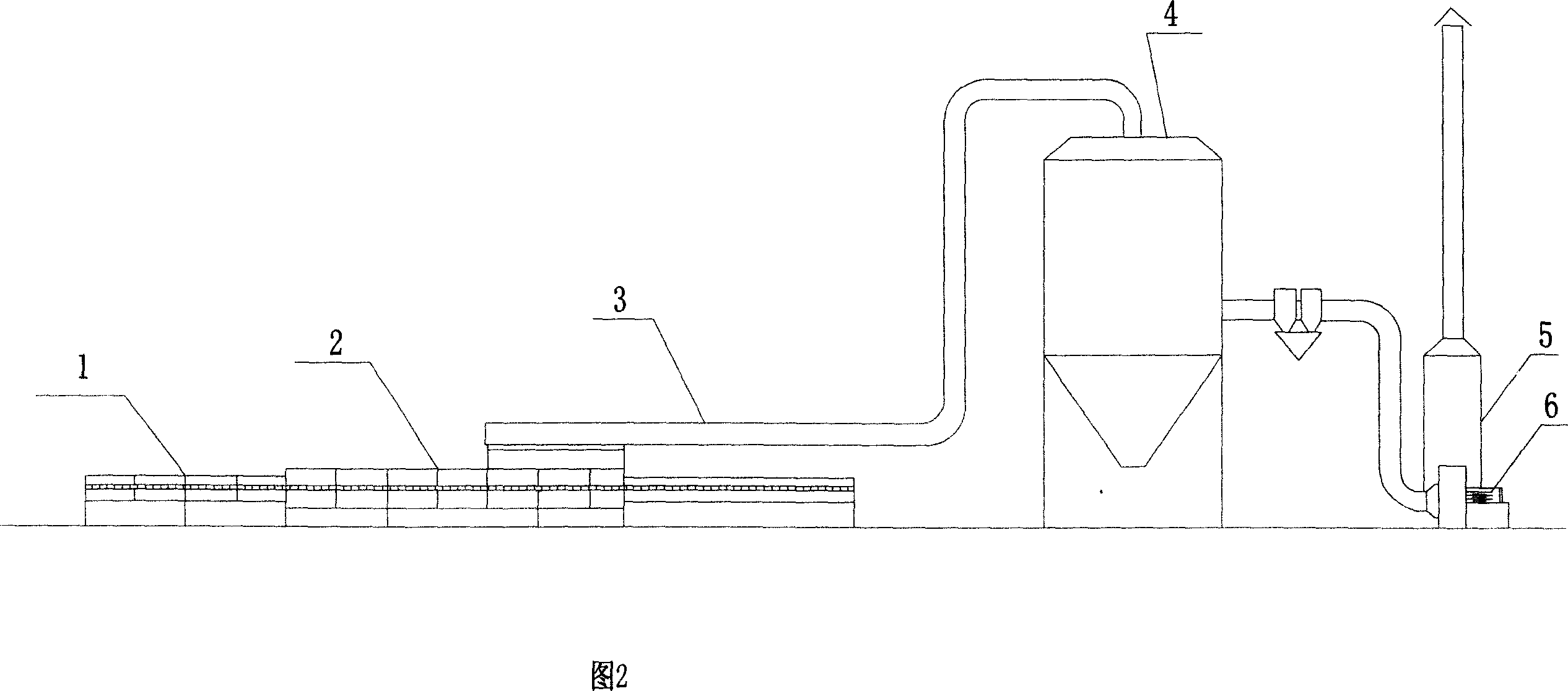

[0017] As shown in Fig. 1 and Fig. 2, the waste heat recovery device of the kiln quenching zone of the ceramic production line of the present invention is to install a hot air pipe 3 on the kiln upper part of the kiln quenching zone 2, and the hot air duct 3 communicates with the furnace chamber , a buffer interlayer is arranged between the upper part of the quenching zone of the kiln and the connected hot air pipe. The upper compartment 7 is plane, the cross section of the lower compartment 8 is arc-shaped, and the two form a vault-shaped structure. The two ends of the upper and lower compartments are fixedly connected with the side wall of the kiln. Silicon carbide plate, the lower compartment 8 is made of mullite or high temperature resistant brick. One end of the hot air pipe 3 communicates with the inner cavity of the upper tower top of the spray drying tower 4, and the other end is connected with the inner cavity of the rear section of the quenching zone 2 of the kiln. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com