System and method for treating wastewater of containing copper from microetching printed circuit board

A wastewater treatment system and printed circuit board technology, applied in water/sewage treatment, extracted water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of impure copper powder, incomplete copper recovery, and large water consumption Resources and other issues, to achieve the effect of difficulty and cost reduction, good economic benefits, and simple processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

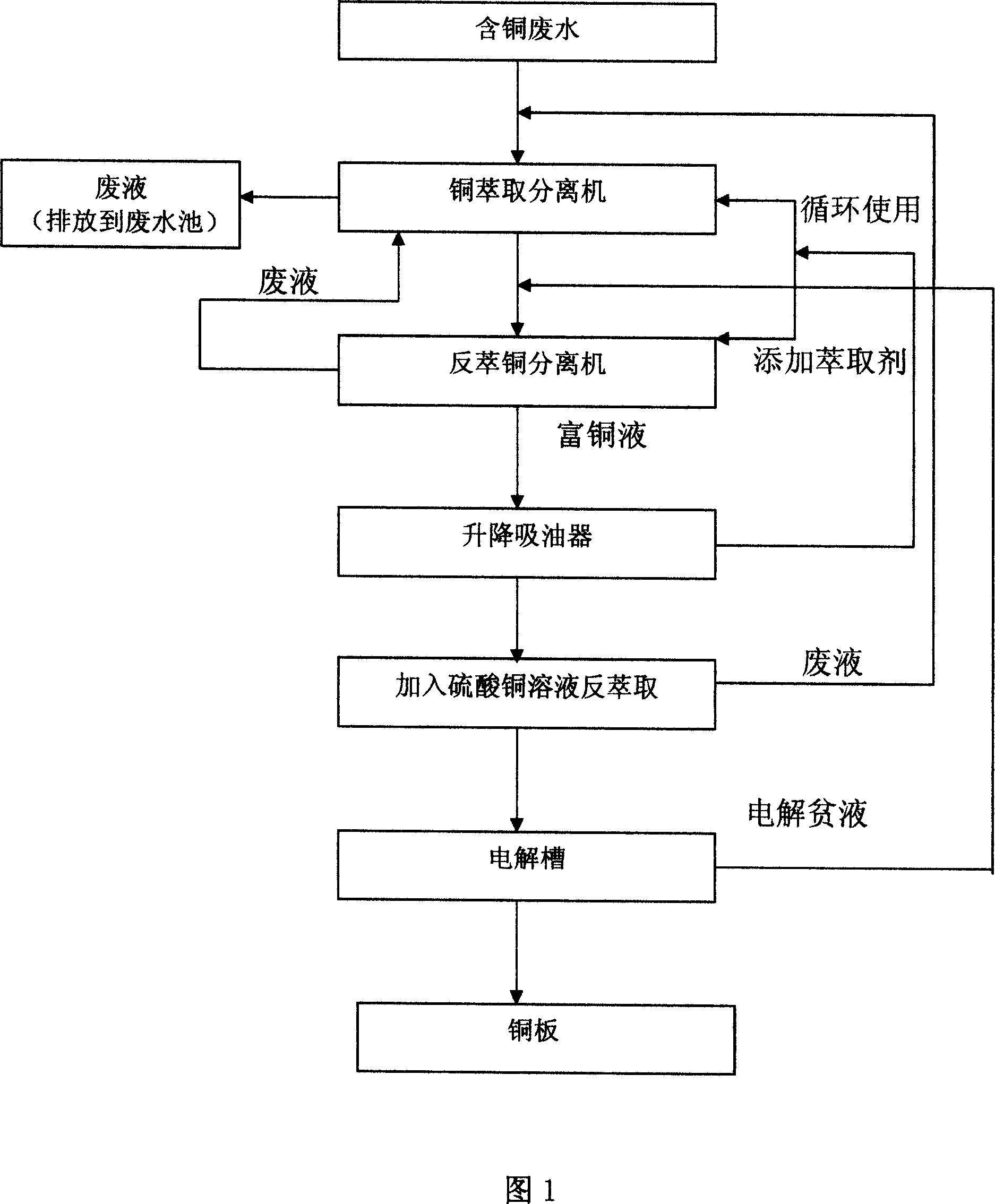

[0023] A copper-containing waste water treatment system for printed circuit board micro-etching, the system includes a copper separation system, an electrolysis system, a waste water pre-treatment system and a waste water post-treatment system, and the copper separation system includes two extractors that work in circulation, namely the copper extractor separator And back extraction copper separator; electrolysis system includes electrolytic cell, sodium hypochlorite electrolytic membrane, 200AM2 current, 1MM copper plate, wastewater pre-treatment system includes copper-containing wastewater tank, PH automatic detector, gas spiralizer, wastewater post-treatment system includes oil separator, agitator, lifting oil absorber,

[0024] The PH value automatic detector is placed in the copper-containing wastewater tank to automatically monitor the PH value of the copper-containing wastewater.

[0025] The two extractors work in circulation, the waste liquid treatment capacity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com