Control system in new type computer controlled sewing machine

A control system and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve problems such as high requirements for software programming, high requirements for circuit board technology, and increased difficulty in process production, so as to simplify programming , communication safety and reliability, and the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

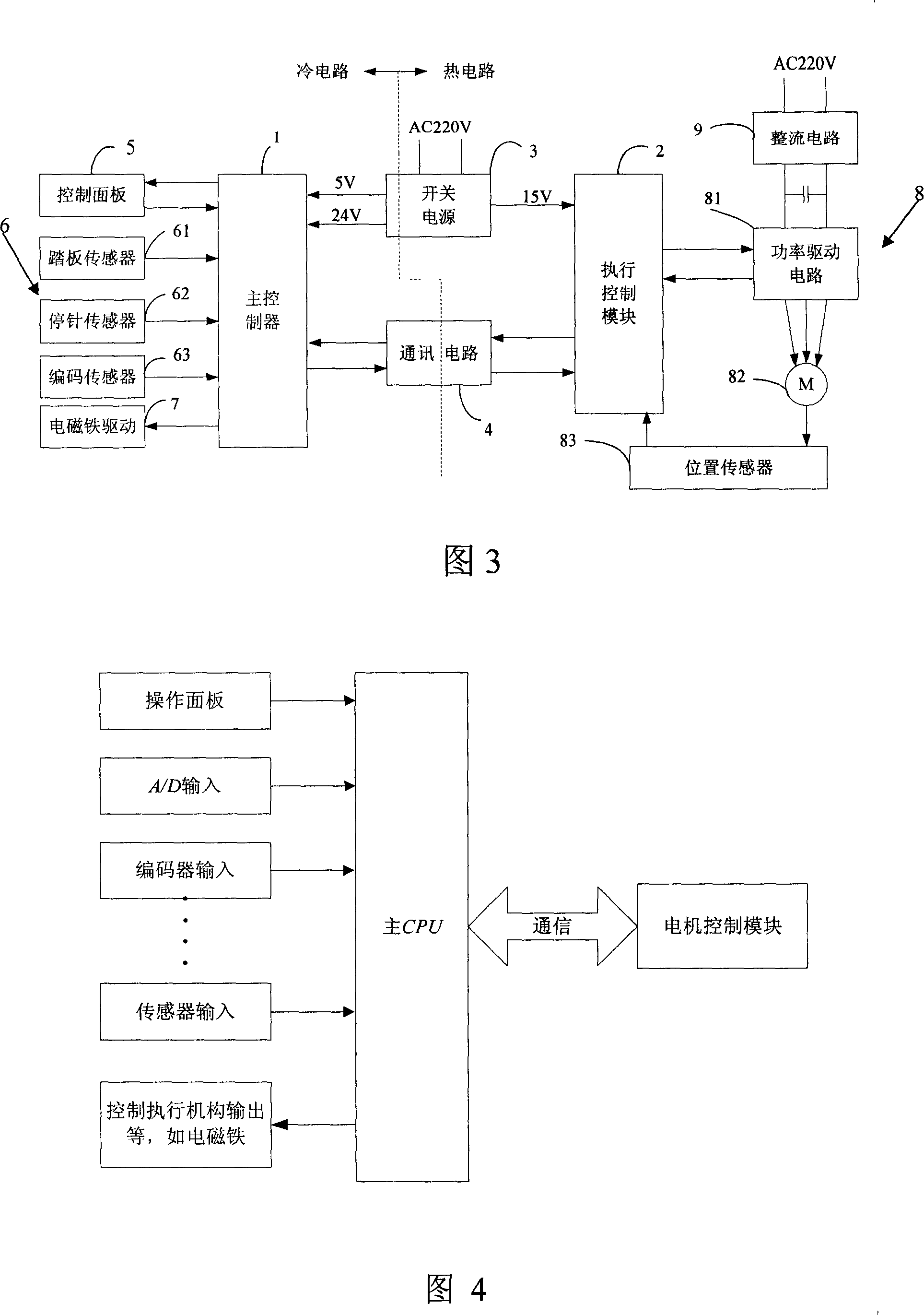

[0036] Please refer to Fig. 3, the novel computerized sewing machine control system includes: a main controller 1, an executive control module 2, a switching power supply 3, a communication circuit 4, a control panel 5, a pedal sensor 61, a needle stop sensor 62, and an encoding sensor 63 The sensor assembly 6, the electromagnet drive circuit 7, the motor power drive circuit 8 and the rectification circuit 9 composed of the power drive circuit 81, the motor 82 and the position sensor assembly 83 are formed.

[0037] The main controller 1 is bidirectionally connected with the control panel 5, and the input ends of the main controller 1 are respectively connected with the output ends of the pedal sensor 61, the needle stop sensor 62, and the encoder sensor 63; the output of the pedal sensor controls the speed of the sewing machine and the operation of each actuator Information; the needle stop position sensor is used to feedback the position of the sewing machine needle.

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com