Method for synthesizing vinyl solution-polymerization butadiene-isoprene rubber adopting composite regulation system

A technology of solution-polymerized butadiene-butadiene rubber and a polymerization method, which is applied in the field of polymerization of solution-polymerized butadiene-butadiene rubber, and can solve the problems of no public coupling, inability to separate, and no mention of the synthesis of solution-polymerized butadiene-butadiene rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

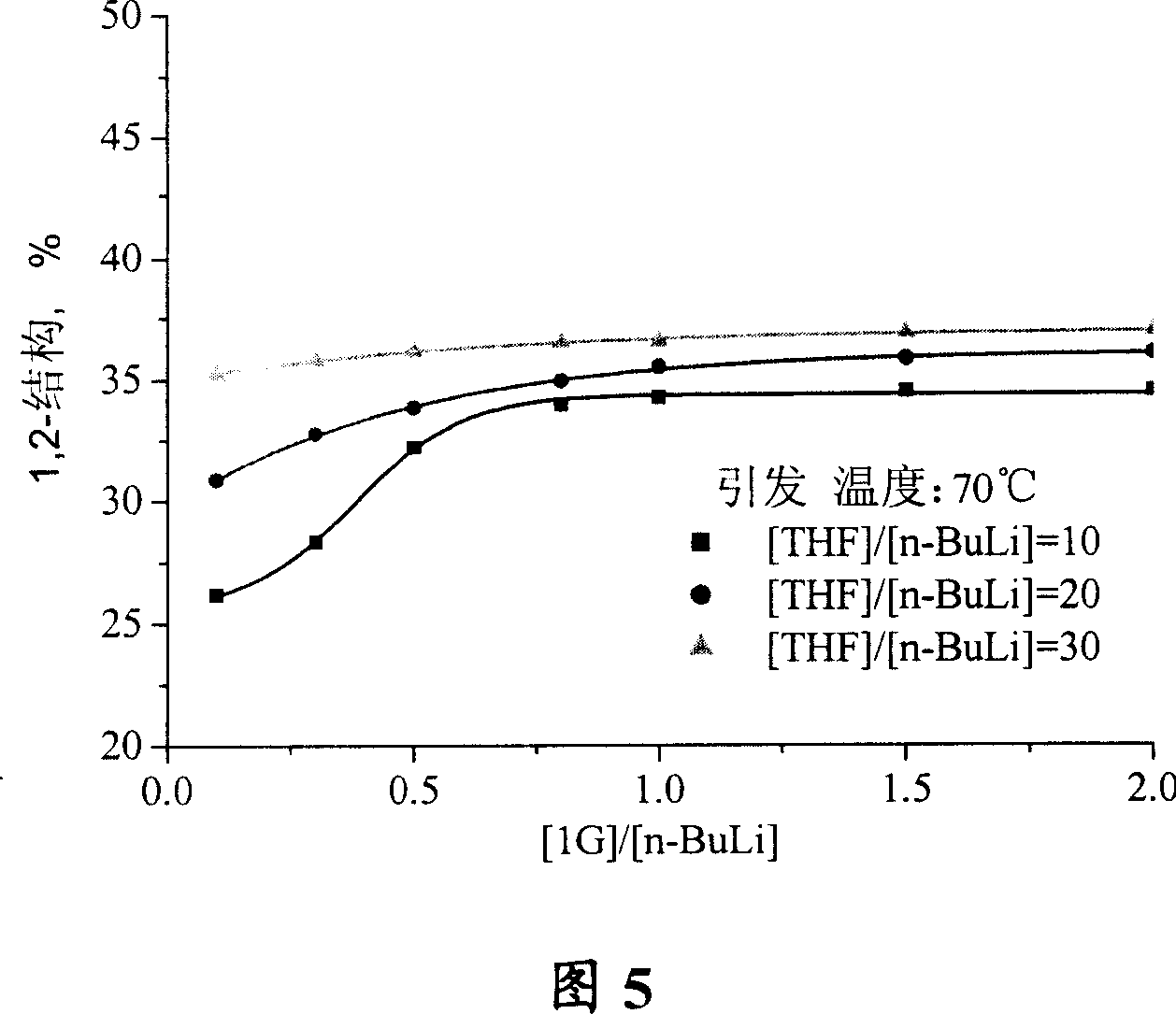

[0042] Embodiment 1 adopts 1G / THF as composite structure regulator, and cyclohexane / n-hexane mixed solvent (=88 / 12, weight ratio) system is synthesized star-shaped solution polybutadiene rubber (BD / IP=70 / 30, weight ratio )

[0043] The polymerization is carried out in a 5-liter stainless steel reactor. After the reactor is soaked with cyclohexane / n-hexane, it is evacuated and filled with nitrogen (high-purity nitrogen) for three times. The reactor is heated by hot oil and cooled by cold oil. The temperature of the hot oil is set to Set at 50°C, and the cold oil temperature at 30°C. First, 2600 g of refined cyclohexane / n-hexane, 271.95 g of butadiene, and 116.55 g of isoprene were added in one go. Then add 1G and THF according to the designed amount, heat the reaction material with hot oil, and when the temperature in the reactor rises to 50°C, control the ratio of hot oil and cold oil to keep the temperature of the material stable, and then add miscellaneous killing and initi...

Embodiment 2

[0073] Example 2 Using 1G / THF (1G / THF / Li molar ratio: 0.8 / 30 / 1) as composite structure regulator, cyclohexane / n-hexane mixed solvent (=88 / 12, weight ratio) system to synthesize star-shaped soluble polybutylene Rubber (BD / IP=70 / 30, weight ratio)

[0074] The preparation method of the copolymer and the test of the microstructure in the polymer are the same as in Example 1, except that the initiation temperature is 70°C. The relationship between the 1,2-structure in the product and the amount of 1G / THF added is shown in Figure 5. The coupling efficiency and physical and mechanical properties of the products are shown in Table 5.

[0075] Table 5 Coupling efficiency and physical and mechanical properties of star-shaped solution polybutylene rubber

Embodiment 3

[0076] Example 3 Using 1G / THF (1G / THF / Li molar ratio: 0.8 / 30 / 1) as composite structure regulator, cyclohexane / n-hexane mixed solvent (=88 / 12, weight ratio) system to synthesize star-shaped soluble polybutylene Rubber (BD / IP=50 / 50, weight ratio)

[0077] The preparation method of the copolymer and the test of the microstructure in the polymer are the same as in Example 1, except that the amount of raw materials added is 2600 g of cyclohexane / n-hexane, 194.25 g of butadiene, and 194.25 g of isoprene. The coupling efficiency and physical and mechanical properties of the products are shown in Table 6.

[0078] Table 6 Coupling efficiency and physical and mechanical properties of star-shaped solution polybutylene rubber

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com