Filling member filled with lightweight material and method for manufacturing same

A light-weight material and light-weight filler technology, applied in the direction of building materials, etc., can solve the problems of debris polluting the construction environment, not being able to degrade naturally, easy to be scratched and cracked, and achieve simple, pollution-free and economical production and processing processes and applicability, the effect of flexible cross-sectional shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

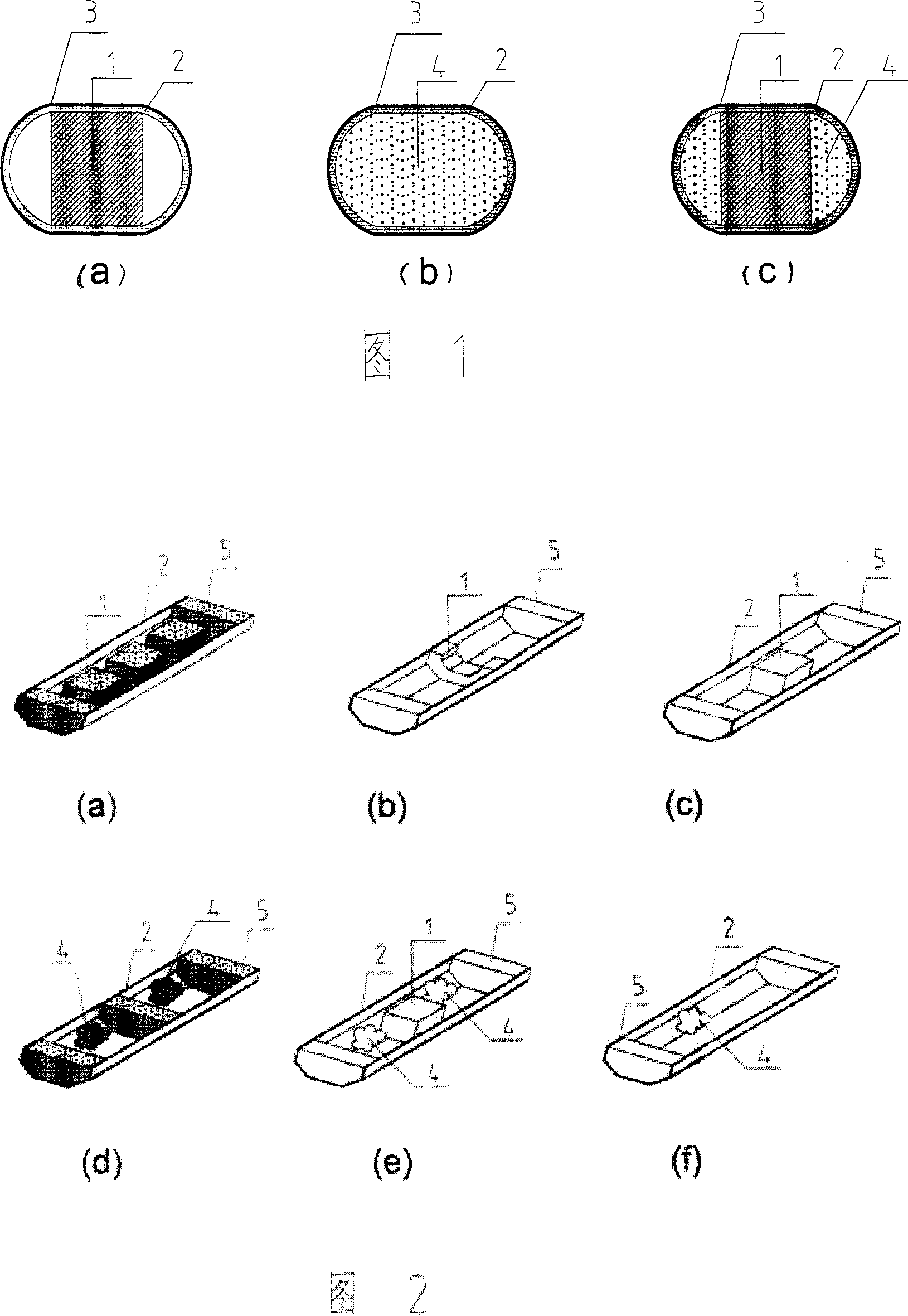

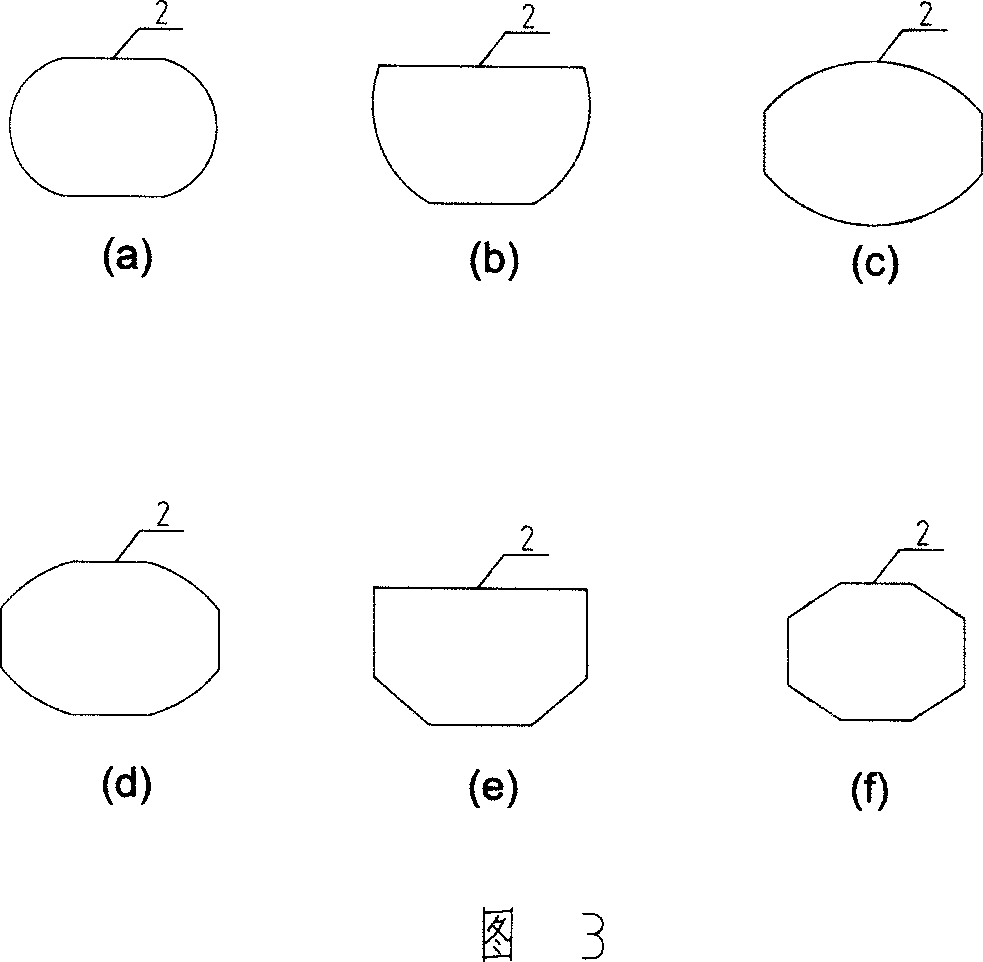

[0035] As shown in Fig. 1 (a)-(c) and Fig. 2 (a)-(f), the filler of the present invention is formed by filling by light material, comprises by thin shell layer 2 and is arranged on thin shell layer 2. The hollow shell formed by the plugging ends 5 at both ends is filled with at least one light material support member 1 in the shell, and a sealing surface 3 is provided outside the shell, and the sealing surface 3 is a rubberized layer, which can also Layers of tape that are wound around the tape. The thin shell layer 2 is made of glass fiber reinforced plastic material or rubber-plastic composite material with certain strength and toughness, and it can also be made of other materials with certain strength and toughness. The material of the plugging end 5 is the same as that of the support member 1, and the thickness is 5 cm. In this wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com