Producing method of composite cooking-vessel and product thereof

A technology of cooking utensils and production methods, which is applied in the field of kitchen utensils, can solve the problems of affecting the service life of cooking utensils, complex gap structures, and unsustainable heat storage, and achieve the effect of rapid heating, simple process flow, and long-lasting heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

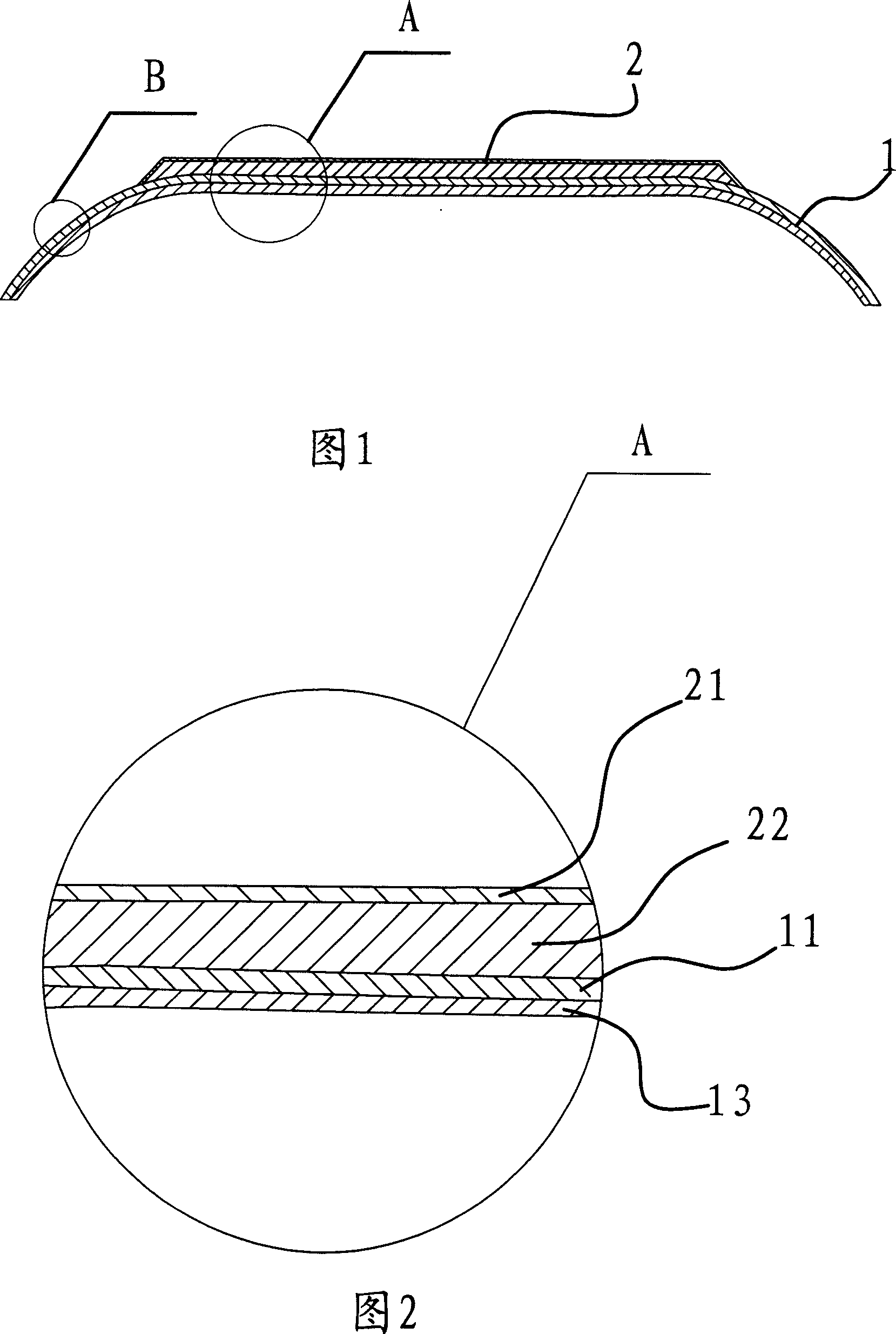

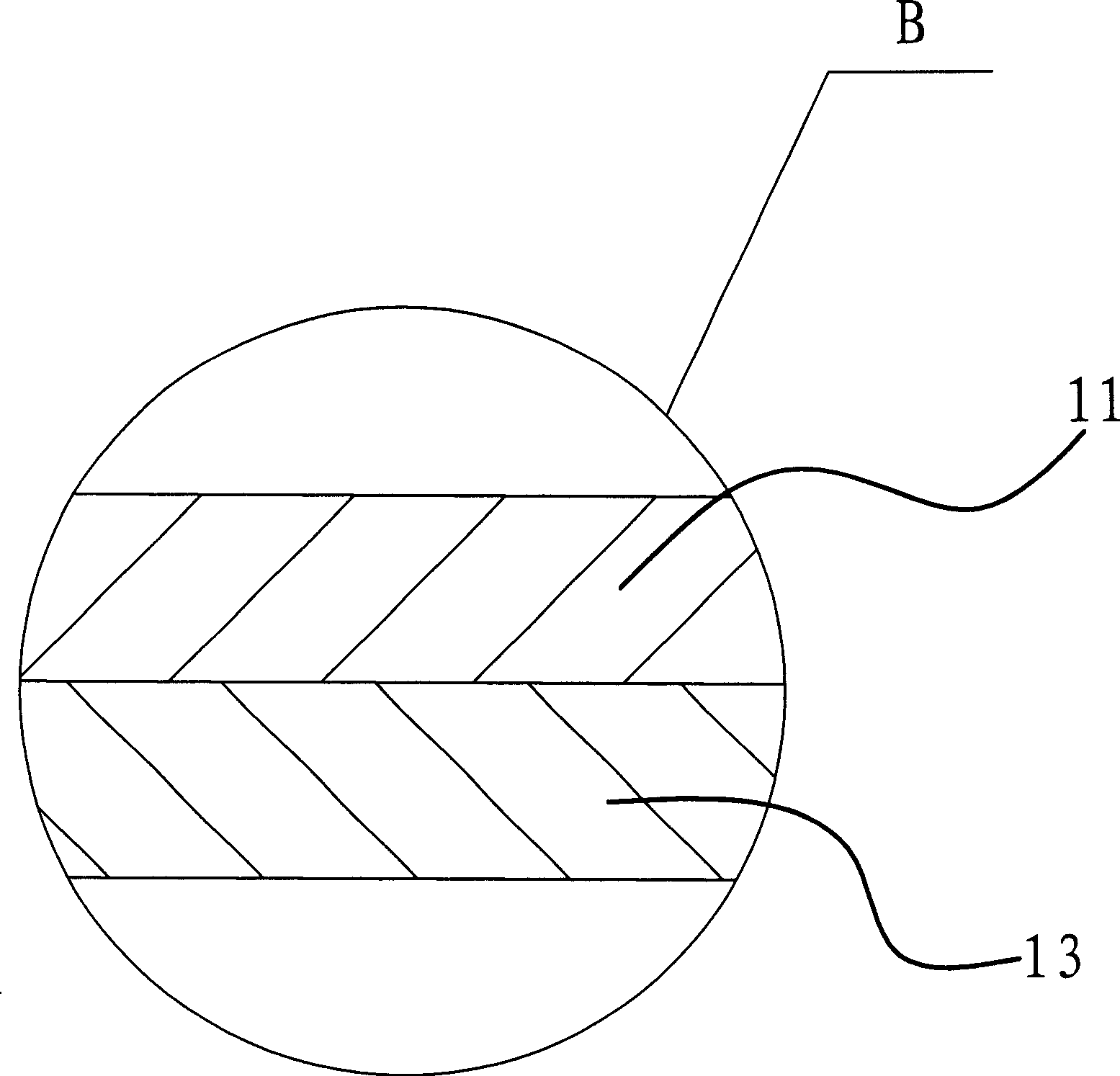

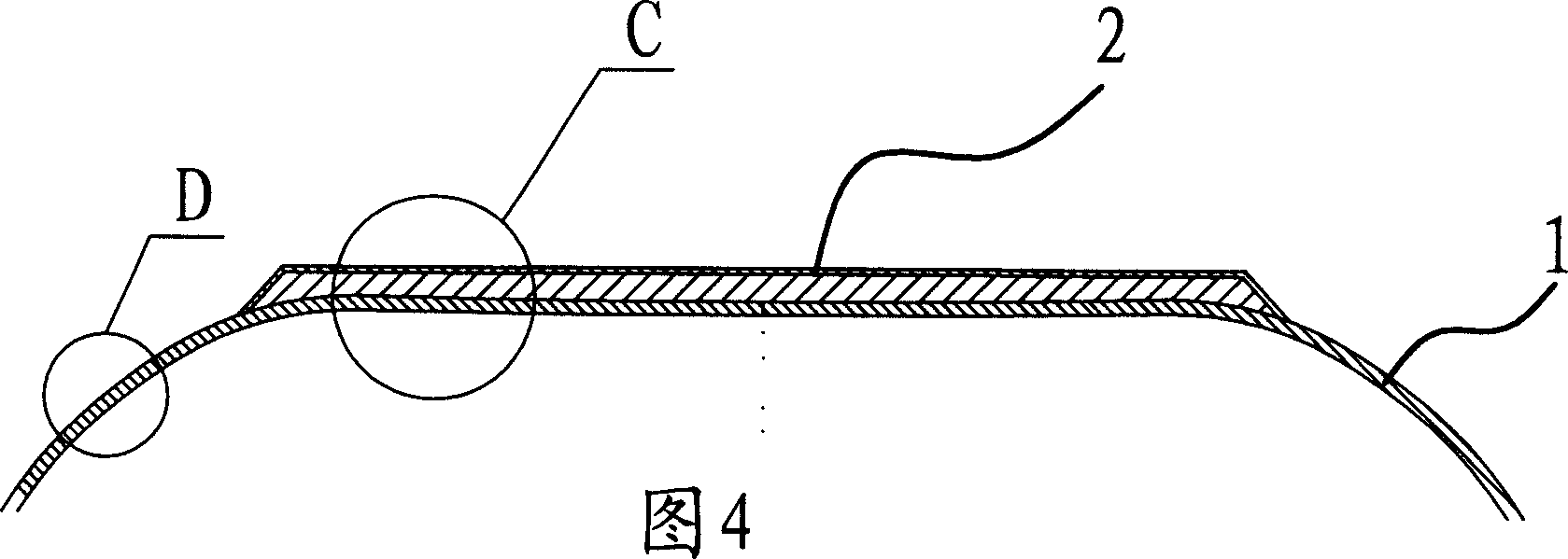

[0039]One: The production of two-layer composite cooking utensils

[0040] A. Production of cooking utensil body:

[0041] a, material selection, cold rolling: select the aluminum alloy and martensitic stainless steel that model is 1050 for use; Then carry out cold rolling into metal plate by two kinds of metal materials by rolling machine (model: RP170-110, manufactured by CITIC Heavy Machinery Co., Ltd.), The thickness of the aluminum alloy plate after cold rolling is 5.0mm, and the thickness of the martensitic stainless steel plate is 1.5mm;

[0042] b. Cleaning and drying: place the above-mentioned cold-rolled aluminum alloy and martensitic stainless steel in a cleaning machine (manufactured by Zhaoqing Second Machine Tool Co., Ltd.) for 5 minutes, and then dry them at a temperature of 40°C Dry;

[0043] c. Roll pressing: The above-mentioned cleaned and dried metal plates are placed in the tunnel furnace (Shenzhen City Fengyu Electromechanical Equipment Manufacturing Co...

Embodiment 2

[0052] One: The production of three-layer composite cooking utensils

[0053] A. Production of cooking utensil body:

[0054] a. Material selection and cold rolling: select pure aluminum, martensitic stainless steel and ferritic stainless steel; Metal sheet, the thickness of pure aluminum sheet after cold rolling is 1.0mm, the thickness of martensitic stainless steel sheet is 0.3mm; the thickness of ferritic stainless steel sheet is 1.5mm;

[0055] b. Cleaning and drying: Place the above-mentioned cold-rolled pure aluminum plate, martensitic stainless steel plate and ferritic stainless steel plate in (manufactured by Zhaoqing Second Machine Tool Co., Ltd.) for 30 minutes, and then at a temperature of Dry at 75°C;

[0056] c. Spot welding and rolling: place the above-mentioned cleaned and dried metal plate through a spot welding machine (model: WL-SP-150K, manufactured by Huizhou Huashi Welding Equipment Manufacturing Factory) and place it in the tunnel furnace (manufactured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com