Method of purifying montmorillonite, purified montmorillonite and composition thereof

A technology of montmorillonite and slurry, which is applied in the field of separation and purification of inorganic minerals, can solve the problems of difficult control of product quality, high cost, and long purification cycle, and achieve the effects of compact structure, improved purity, and difficult concentration and dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1 Purification of Montmorillonite

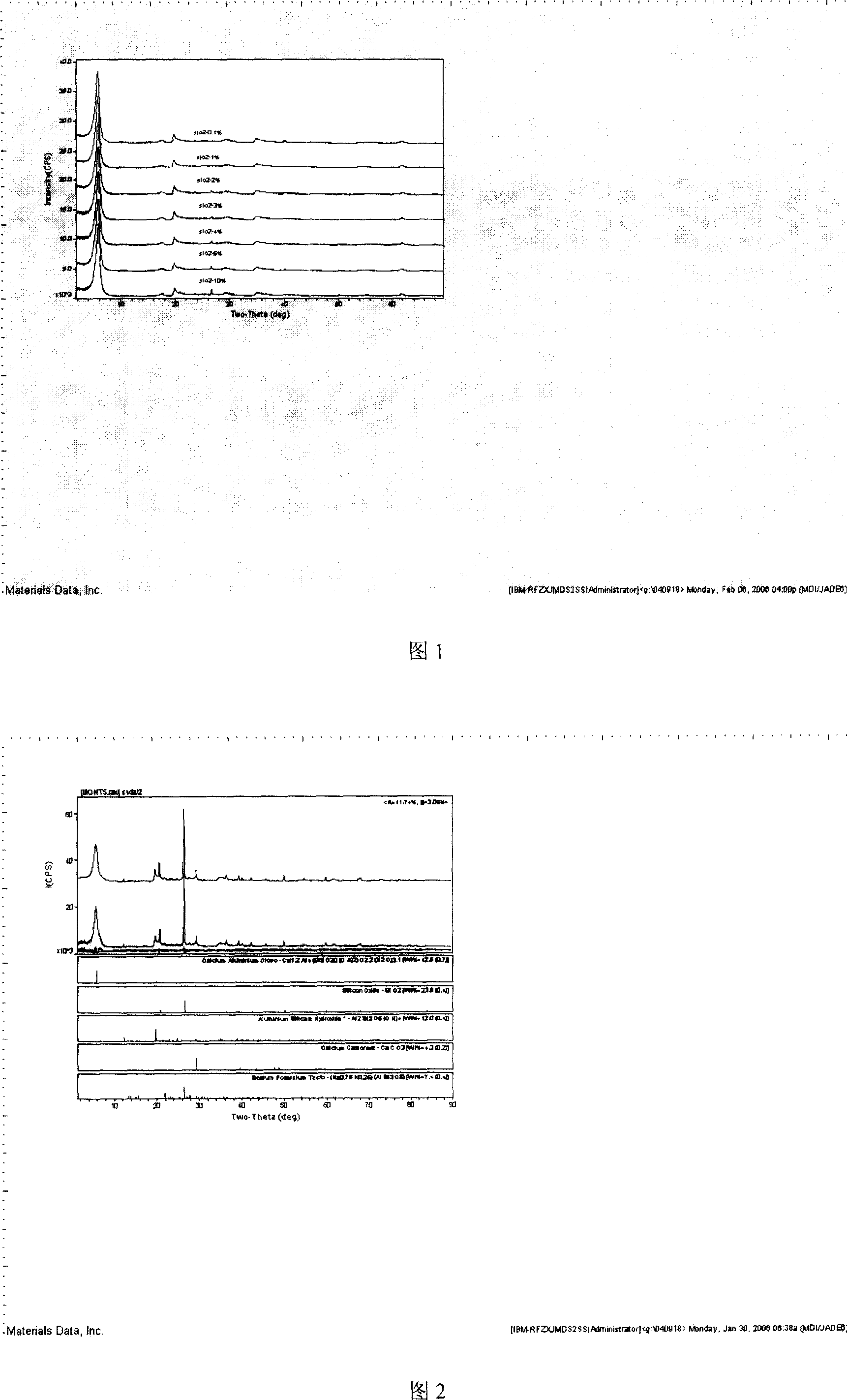

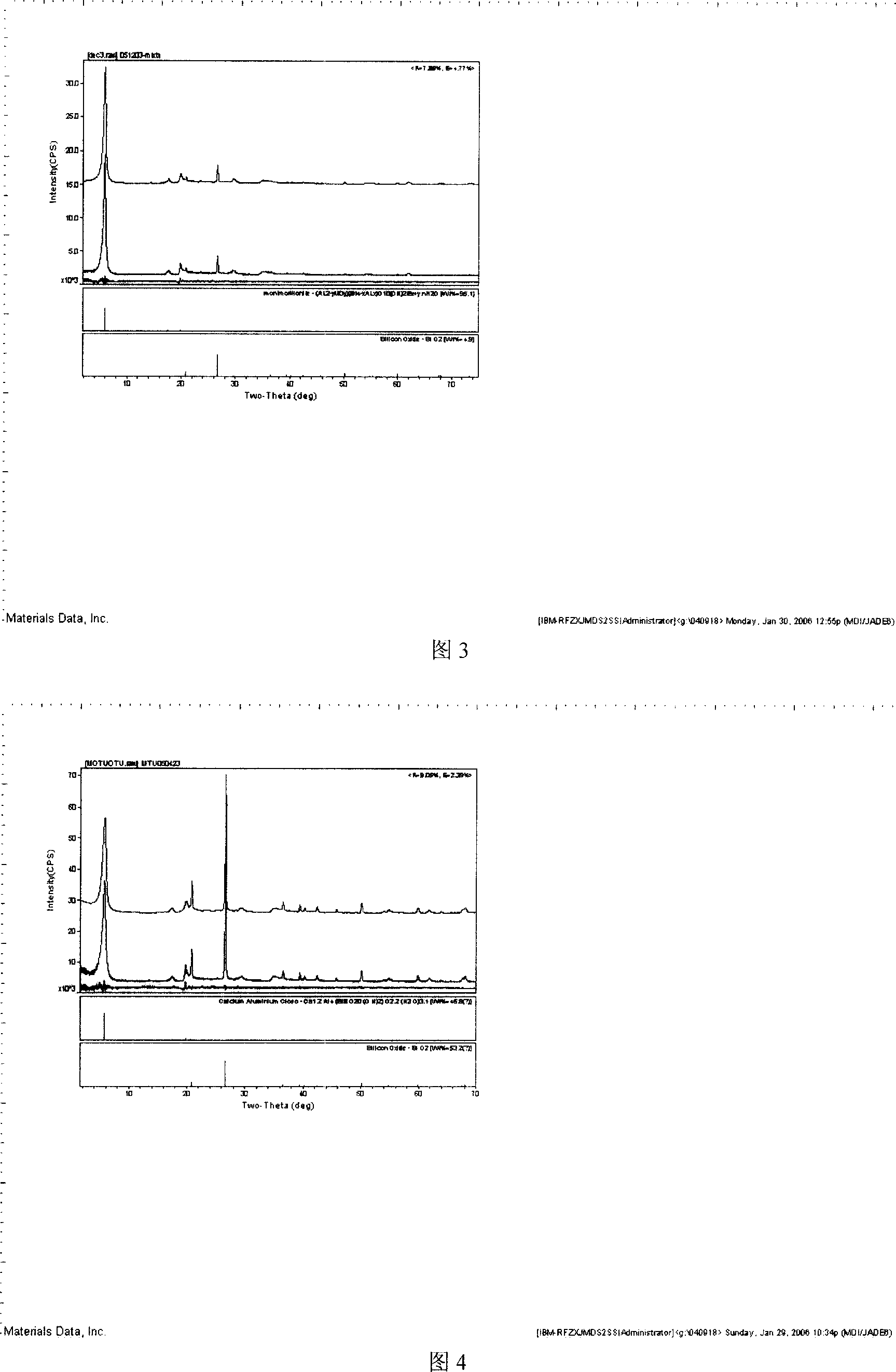

[0064] Mineral composition of raw bentonite: montmorillonite 42.5%, α-quartz 33.9%, kaolin 12.0%, feldspar 7.4%, calcite 4.3%, see Figure 2.

[0065] The raw ore is dried, crushed, passed through a 50-mesh sieve, added water and 0.3% sodium hexametaphosphate of raw ore powder to form a slurry with a solid content of 20%, stirred for two hours, passed through a three-stage hydrocyclone, and separated The slurry is mixed with water to make a thin slurry with a solid content of 3%, which is separated in a disc centrifuge, and the separated thin slurry is concentrated in another disc centrifuge, and the concentrated slurry is passed through a plate and frame filter press After pressure filtration, a filter cake with a solid content of 40-50% is obtained. The filter cake is dried at 120° C. and crushed to a size above 500 mesh.

[0066] The mineral composition of the purified montmorillonite is 95.1% montmorillonite and 5.1% α-...

Embodiment 2

[0067] Example 2 Purification of Montmorillonite

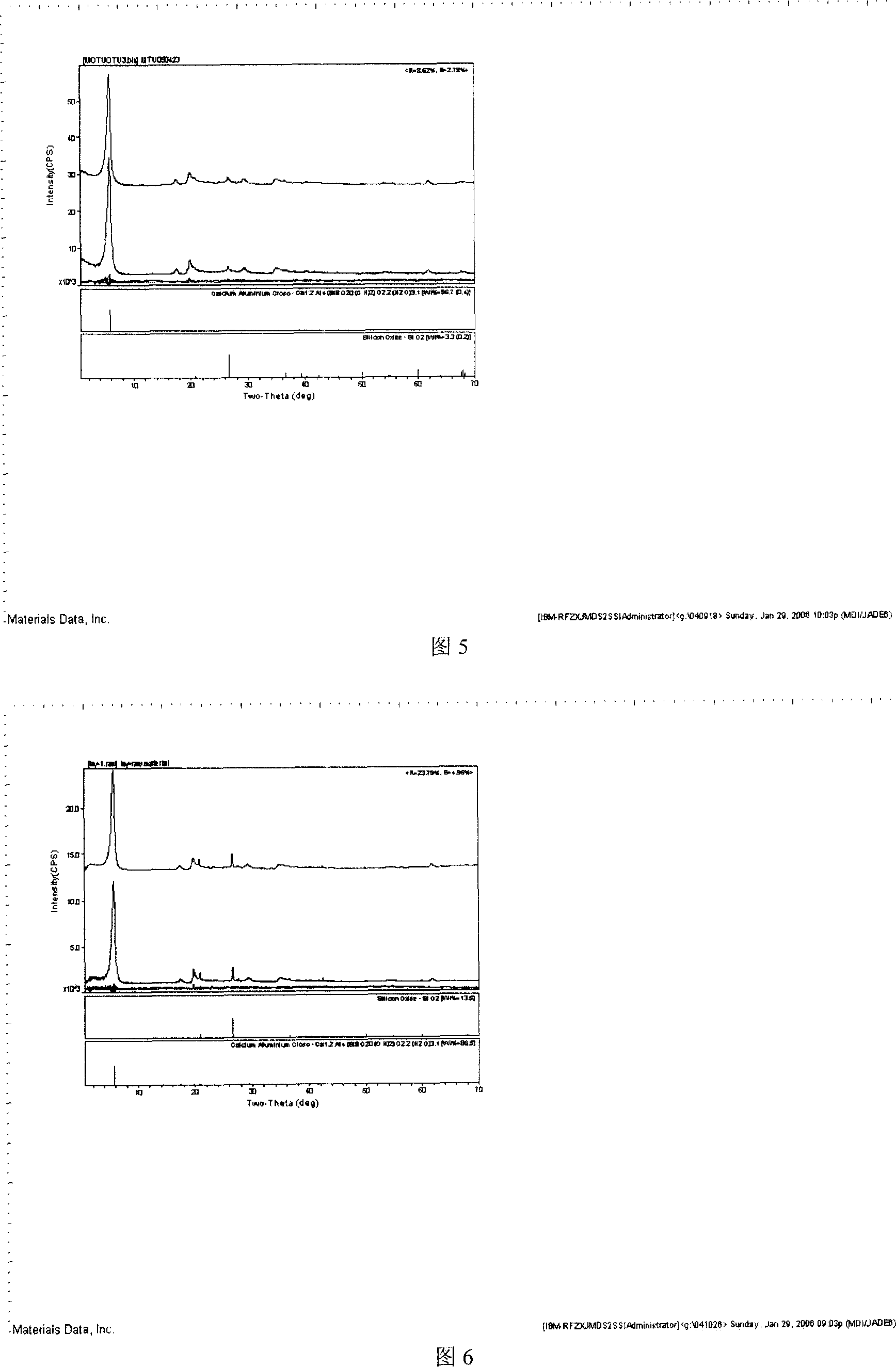

[0068] Mineral composition of raw bentonite: montmorillonite 46.8%, α-quartz 53.2%, see Figure 4.

[0069] The raw ore is dried, crushed, passed through a 50-mesh sieve, added water and 0.5% sodium polyacrylate powder of the raw ore to make a slurry with a solid content of 15%, stirred for two hours, passed through a four-stage hydrocyclone, and separated Add water to the slurry to make a thin slurry with a solid content of 3%, enter the disc centrifuge for separation twice, and the separated thin slurry enters another disc centrifuge to concentrate, and the concentrated slurry is pressed through the plate and frame After pressing by the filter machine, a filter cake with a solid content of 40-50% is obtained. The filter cake is dried at 120° C. and crushed to a size above 500 mesh.

[0070] The mineral composition of the purified montmorillonite: 96.7% montmorillonite, 3.3% α-quartz, see Figure 5. The recovery rate is 6...

Embodiment 3

[0071] Example 3 Purification of Montmorillonite

[0072] Mineral composition of raw bentonite: 86.5% montmorillonite, 13.5% α-quartz, see Figure 6.

[0073] The raw ore is dried, crushed, passed through a 50-mesh sieve, added water and 0.8% sodium hexametaphosphate of raw ore powder, and made into a slurry with a solid content of 25%. After stirring for two hours, it passes through a three-stage hydrocyclone, The separated slurry is mixed with water to make a thin slurry with a solid content of 3%, and it is separated once in a disc centrifuge, and the separated thin slurry is concentrated in another disc centrifuge, and the concentrated slurry passes through the plate frame After pressing by a filter press, a filter cake with a solid content of 40-50% is obtained. The filter cake is dried at 120° C. and crushed to a size above 500 mesh.

[0074] Mineral composition of purified montmorillonite: 97.0% montmorillonite, 3.0% α-quartz, see Figure 7. The recovery rate is 75%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com