Non-filling type nucleic acid extraction device and its preparing method and application

A non-filled, nucleic acid technology, which is applied to non-filled nucleic acid extraction devices and its application in nucleic acid extraction, can solve the problems of high processing costs and difficult to make plastic substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1. Preparation of sandwich-type non-filled nucleic acid extraction device and detection of its nucleic acid extraction effect

[0048] 1. Preparation of sandwich-type non-filled nucleic acid extraction device

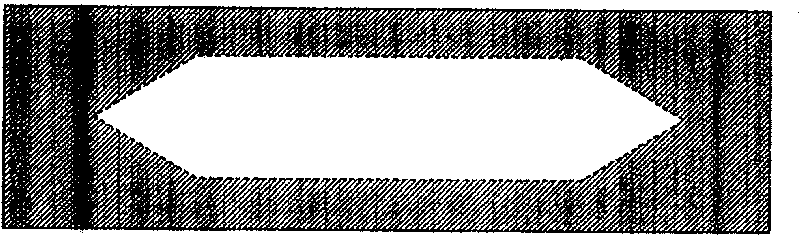

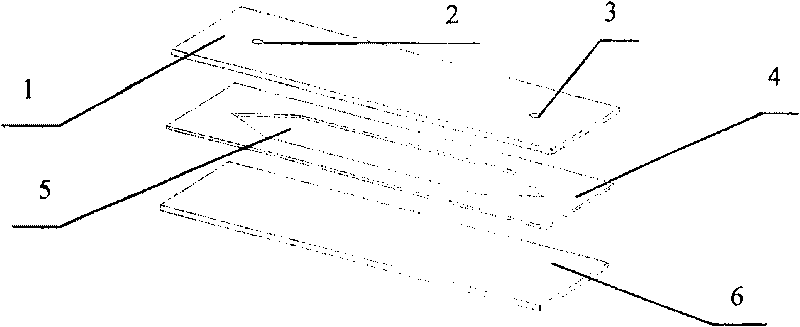

[0049] In this embodiment, the commonly used plastic material PMMA (polymethyl methacrylate) is used as a base material to prepare a sandwich-type non-filled nucleic acid extraction device. The sandwich-type non-filled nucleic acid extraction device consists of two plastic substrate layers (one layer is cover body, one layer is the bottom plate) and an intermediate layer in the middle, the three-dimensional view of its decomposed structure is shown in figure 2 , its preparation method comprises the following steps:

[0050] 1) First process the plastic substrate layer and the middle layer into such figure 2 The shape and size shown: The length of the plastic substrate layer is 75mm, the width is 25mm, and the thickness is 1mm. One of them is used as t...

Embodiment 2

[0061] Example 2. Preparation of Pipeline Non-Filled Nucleic Acid Extraction Device and Detection of Its Nucleic Acid Extraction Effect

[0062] 1. Preparation of pipeline-type non-filled nucleic acid extraction device

[0063] 1. Micromachining of pipes

[0064] Compared with other ways of processing pipelines with polymer materials (hot pressing, pouring, injection molding, LIGA, etc.), micromachining is a faster and cheaper way to process microstructures with polymer materials. In addition, since there is no need to make a mold, the produced graphics do not need to be limited by the mold graphics, so this method has the advantage of being flexible and easy to use, and the drawings can be modified at any time to produce different graphics. prepared by micromachining Image 6 The shown pipeline-type non-filled nucleic acid extraction device (also known as pipeline-type PMMA nucleic acid extraction chip) of the present invention has a size of 104mm×70mm. The production meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com