Method for determining pyrazine compound in spirit

A compound, the technology of pyrazine, which is applied in the field of wine flavor research, can solve the problems of large sample consumption, cumbersome steps, and large loss of analytes, and achieve the effects of improved recovery, high sensitivity, and strong specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

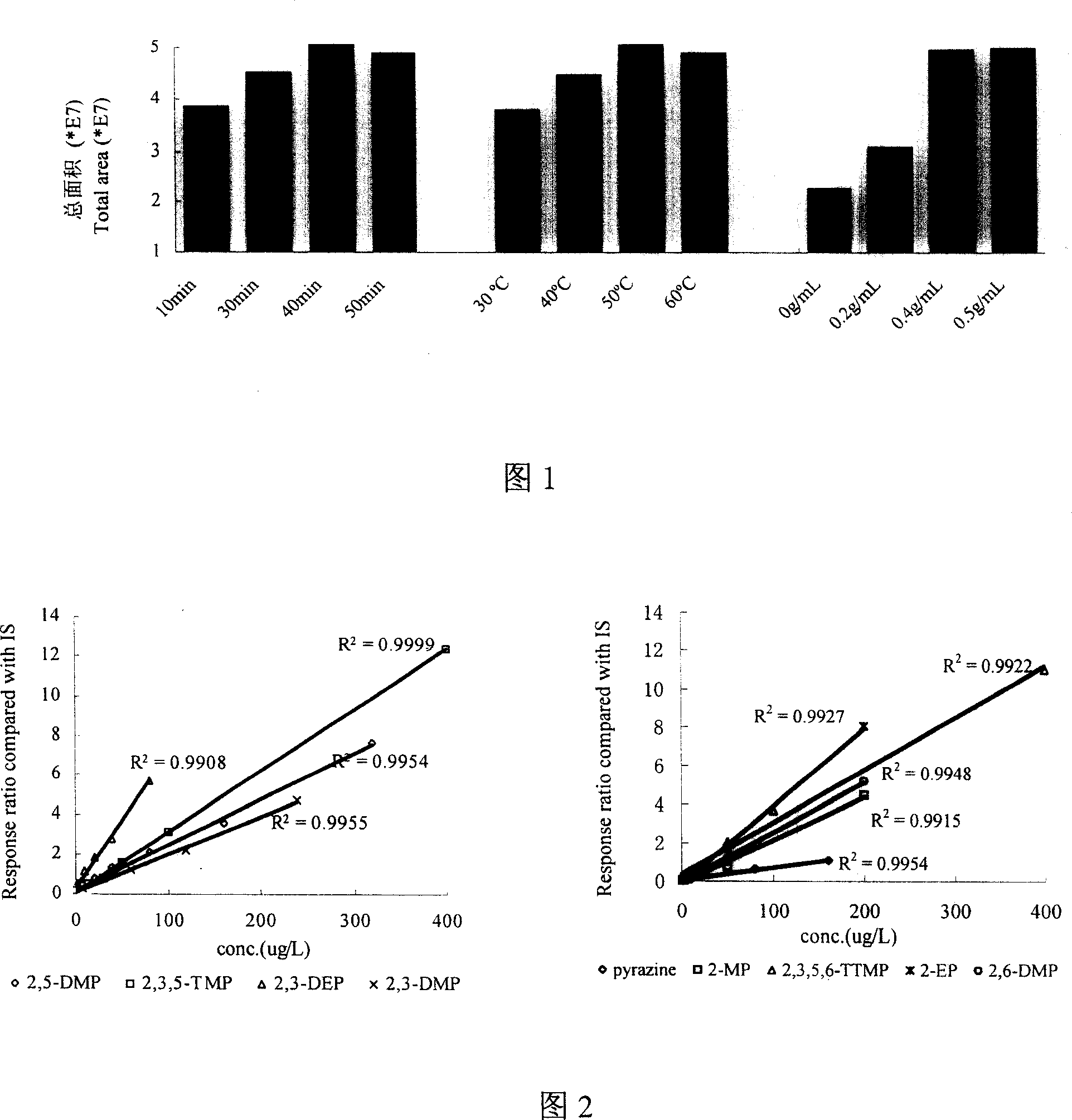

[0028] Optimization of solid phase microextraction conditions:

[0029] The effect of extraction temperature on adsorption sampling is two-sided: on the one hand, more analytes will escape from the matrix into the headspace when the temperature rises, which is beneficial to the headspace solid phase microextraction; on the other hand, the temperature Increasing will also reduce the ability of the extraction head to adsorb analysis components, resulting in a decrease in adsorption capacity. The present invention compares the extraction effects at 30°C, 40°C, 50°C and 60°C, and the result shows that the adsorption effect is the best at 50°C.

[0030] The solid phase microextraction process is a process of enrichment and equilibrium of the analyte between the sample matrix and the coating of the extraction head. Once the equilibrium is reached, the concentration of the analyte between the two phases becomes constant. The present invention compares the extraction effects of 10min, 30m...

Embodiment 2

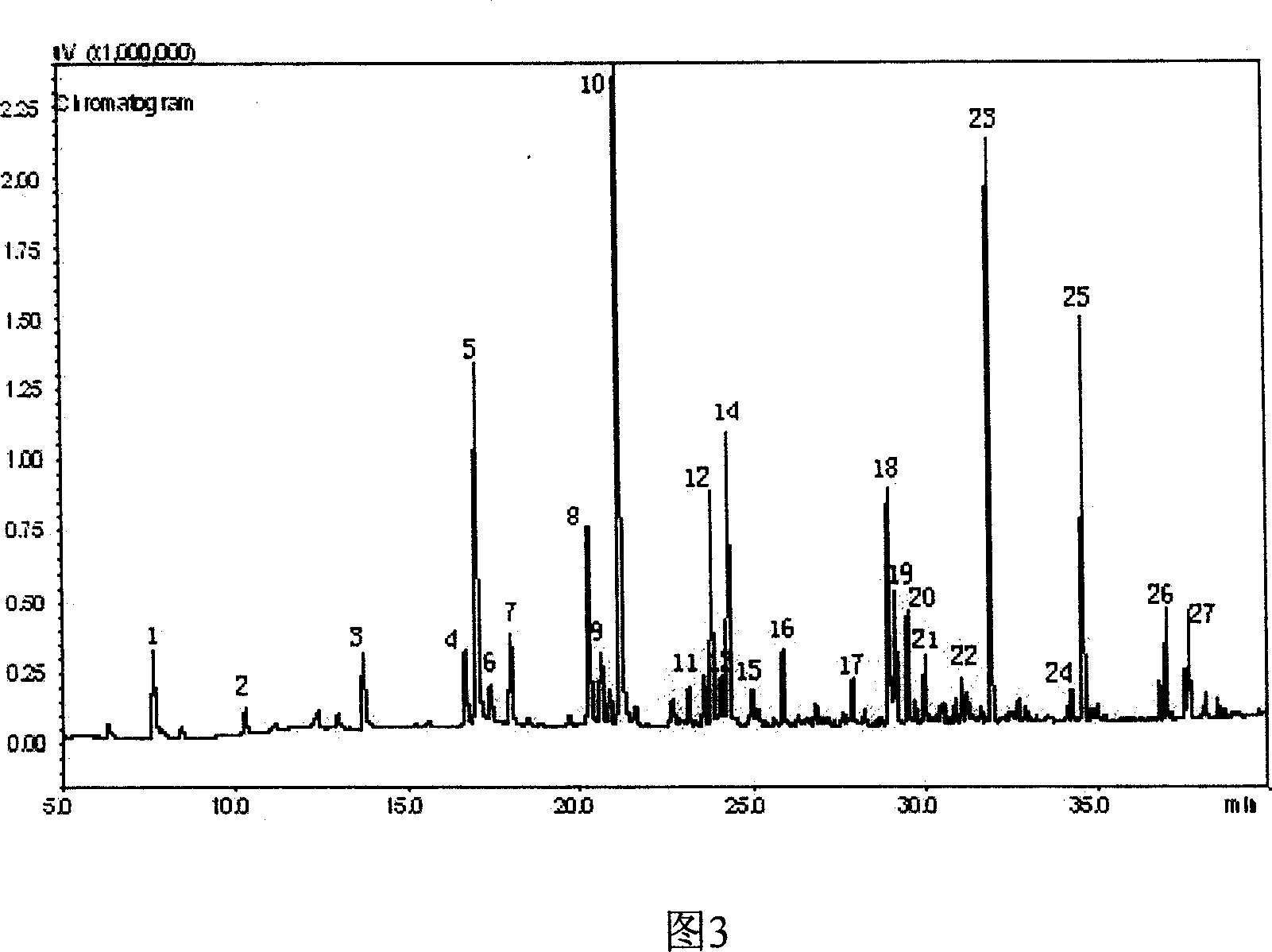

[0033]Evaluation of the method: Using 2-acetylpyridine as the internal standard, the linear correlation coefficient R2 of 9 pyrazine compounds varies from 0.9908 (2,3-dimethylpyrazine) to 0.9999 (2,3,5-tri Between methylpyrazine), the linearity of the obtained standard curve is good, see Figure 2. At the same time, the linear range of the standard curve includes the concentration range of nitrogen compounds in the wine. The detection limit of 9 pyrazine compounds was less than 1μg / L, among which the detection limit of 2,3-DEP was 62.50ng / L. The overall accuracy of this method is good, and the relative standard deviation is mostly within 10%, which can meet the requirements of analysis. The present invention has done the determination of the recovery rate, and the result shows that the recovery rate of this method is all greater than 80%, as shown in Table 1.

[0034] Table 1 Recovery rate of pyrazine compounds in liquor (%, n=3)

[0035] Item

[0036] N.D.: Not detected ...

Embodiment 3

[0038] Determination of actual wine samples:

[0039] The present invention selects Moutai, Langjiu, and Gujing Gongjiu as target wine samples, dilutes the three kinds of liquor to 12% (v / v), adds 500 μL of internal standard, and determines the content of pyrazine compounds in it according to the above method. Attached Table 2 lists the content of pyrazine compounds in the tested wine samples, and Figure 3 shows the GC-FTD chromatogram of Langjiu wine samples.

[0040] Table 2 Contents of various pyrazine derivatives in different liquors (Mean±Stdev, μg / L, n=3)

[0041] Item

[0042] N.D.: Not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com