Manufacture method of flexible electrochromic thin films and flexible electrochromic thin films thereof

A thin film preparation and color changing technology, applied in the field of optical materials, can solve problems such as difficulty in realizing large-scale continuous production and large-area operation, complex production process, etc., and achieve the effects of easy large-scale continuous production, simple process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

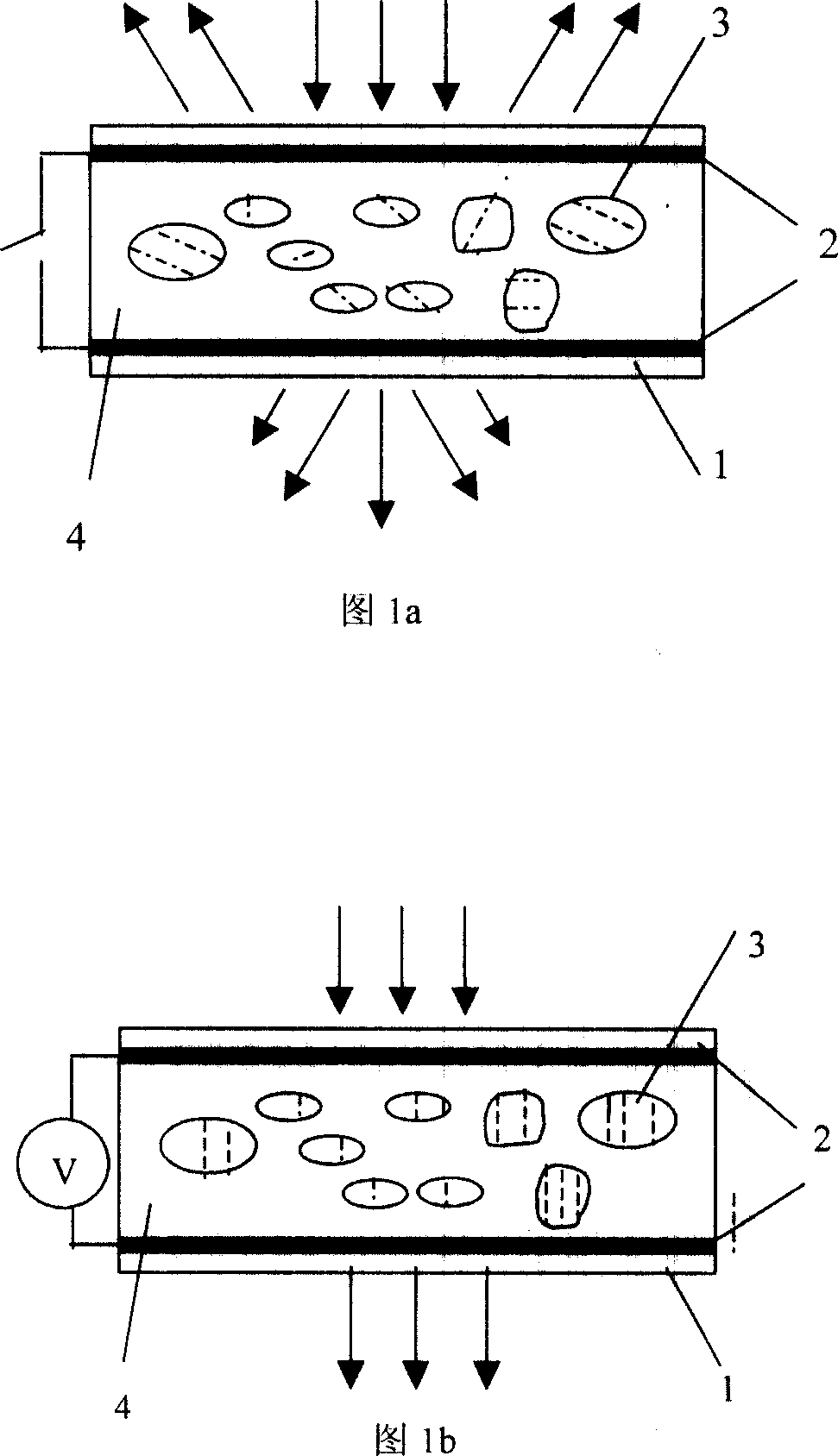

[0031] In a three-neck flask equipped with a condenser tube and a thermometer, add 20g of butyl methacrylate prepolymer, 77g of acetylene bridge liquid crystal and 3g of 1-hydroxycyclohexane phenyl ketone, and stir at 80°C for 30min to make the solution clarify.

[0032] Pour the above clarified solution into the coating roller, coat it on the surface of a polyester conductive film (20Ω / □) with a size of 10cm×10cm, control the speed of the roller to make the thickness of the solution layer 10μm, and then paste another layer through the roller For polyester conductive films of the same size, wires are drawn out from two layers of polyester conductive film layers through conductive graphite glue, and cured under ultraviolet light at 365nm for 2s to obtain a flexible electrochromic film.

Embodiment 2

[0034] In a three-neck flask equipped with a condenser tube and a thermometer, add 40g of butyl methacrylate prepolymer, 58g of acetylene bridge liquid crystal and 2g of 1-hydroxycyclohexane phenyl ketone, and stir at 80°C for 1h to make the solution clarify.

[0035] Pour the above clarified solution into a roller, coat it on the surface of a PI conductive film (100Ω / □) with a size of 20cm×20cm, control the speed of the roller to make the solution layer thickness 50μm, and then paste another layer of the same size through the roller PI conductive film, lead wires on the two layers of PI conductive film through conductive gold glue, and cure it under ultraviolet light at 365nm for 3s to obtain a flexible electrochromic film.

Embodiment 3

[0037] In a three-neck flask equipped with a condenser tube and a thermometer, add 8g of butyl methacrylate prepolymer, 90g of acetylene bridge liquid crystal and 2g of 1-hydroxycyclohexane phenyl ketone, and heat at 80°C under magnetic stirring 1.5h to clear the solution.

[0038] Pour the above clarified solution into a roller, coat it on the surface of a polyester conductive film (80Ω / □) with a size of 50cm×50cm, control the rotation speed of the roller to make the thickness of the solution layer 40μm, and then paste another layer of the same size through the roller The polyester conductive film is used, and the conductive silver glue is used to lead the wires on the two layers of the polyester conductive film for standby, and the ultraviolet light is cured at 365nm for 5s, and the flexible electrochromic film is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com