Process of extracting and preparing deer nerve growth factor (DEER NGF)

A nerve growth factor and deer antler technology, applied in the directions of nerve growth factor, growth factor/inducing factor, nervous system diseases, etc., can solve the problems of no elution peak map, complex production process, harsh conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the pretreatment of deer antler

[0026] Take 0.5kg of fresh velvet antler, use a cryostat to cut the velvet antler into slices with a thickness of 1-2mm, then add an appropriate amount (200mL) of pre-cooled deionized water to pulverize with a homogenizer at 4°C, and perform the homogenization operation until homogenized End when no tissue clumps are visible in the slurry. The homogenate was centrifuged at 5000 revolutions per minute (rpm) for 20 minutes, and the supernatant was collected. Add 200 mL of pre-cooled deionized water to the pellet, resuspend the pellet, centrifuge again at 5000 rpm for 20 minutes, and take the supernatant. Then, repeat the above resuspension and centrifugation process once, and take the supernatant. Combine the supernatants obtained from each centrifugation, put them into a dialysis bag with a molecular weight cut-off of 10,000 Da (purchased from Sigma Company), and dialyze against 0.02mol / L potassium phosphate buffer (pH6.8...

Embodiment 2

[0027] Example 2, Chromatographic Purification of Antler Nerve Growth Factor and Preparation of Freeze-dried Agent

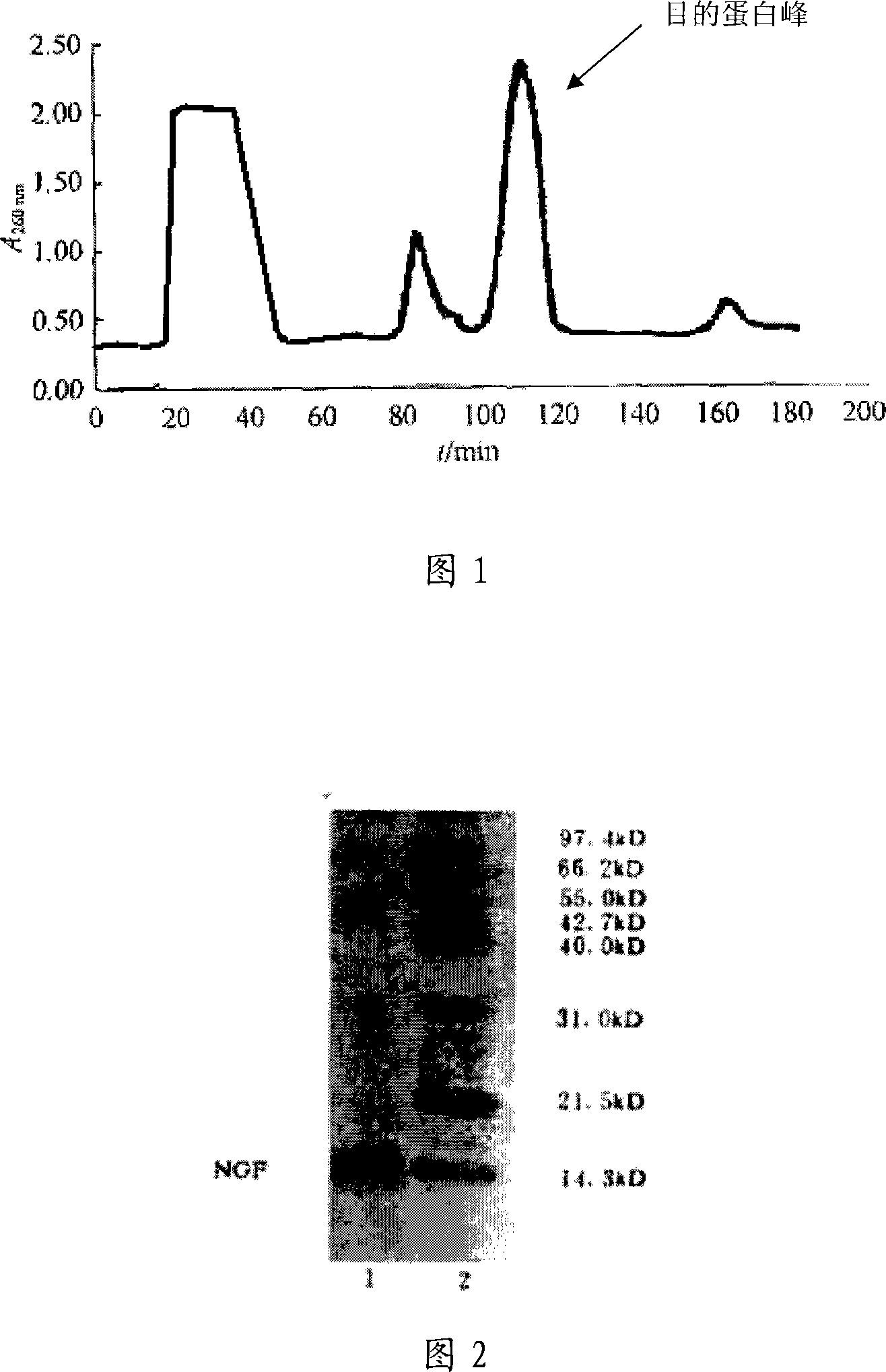

[0028] Add 95mL 0.5mol / L HAc-NaAc damping fluid (pH4.0) to the velvet antler extract solution that obtains in 850mL embodiment 1, make the pH value of solution down to 4.0, then add solid NaCl to wherein again, make in solution The final concentration of NaCl is 0.4 mol / L, mix well and let stand for 10 minutes, then centrifuge at 5000rpm for 5 minutes. Take 900mL supernatant and load it on CM-Cellulose32 column (5.5cm×10cm) (purchased from Pharmacia Company), and then carry out stepwise gradient elution. During stepwise gradient elution, use 400 mL of 0.5 mol / L HAc-NaAc buffer solution (pH4.0) containing 0.8 mol / L NaCl and 350 mL of 0.5 mol / L potassium phosphate containing 0.8 mol / L NaCl at a flow rate of 10 mL / min. Buffer (pH7.0) and 500mL 0.5mol / L potassium phosphate buffer (pH7.0) containing 1mol / L NaCl were eluted and detected at a wavelength of 280nm by an...

Embodiment 3

[0029] Embodiment 3, the detection of nerve growth factor

[0030] Antler nerve growth factor was detected according to the "Molecular Cloning Test Guide" (Science Press, 2002) and the test method of Zhai Lei et al. (Progress in Microbiology and Immunology, 1999, 27(1): 43-46). The antler nerve growth factor solution obtained in Example 2 is carried out to SDS-PAGE (15% polyacrylamide separating gel, 4% stacking gel, 10mA constant current electrophoresis), after the electrophoresis is finished, it is stained with Coomassie brilliant blue, and the photo of the electrophoresis gel is as follows: As shown in Figure 2, there is a single band of nerve growth factor at a molecular weight of about 14kD, and its purity reaches 96% through image analysis. The biological activity of NGF is detected by the growth of the dorsal root ganglion of the chicken embryo: in the blank control group with buffer solution, the dorsal root ganglion of the chicken embryo has no process growth; In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com