Process for preparing expanded product of thermoplastic resin

A technology for thermoplastic resins and foamed products, applied in the field of preparing thermoplastic resin foamed products, can solve the problems of poor appearance, mechanical properties, barrier properties, poor foaming ratio, uneven size distribution, fast diffusion speed, etc., and achieve good physical properties. Mechanical properties, effective cell diameter, high foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1, PMMA foamed product

[0030] The vacuum-dried polymethyl methacrylate (PMMA) was melted and pressed at 200° C., and quenched in cold water to prepare a 1 mm thick sample.

[0031] The above PMMA sample was placed in an autoclave, and 20°C / 12MPa CO 2 After 6 hours of constant temperature and pressure, the sample was taken out from the autoclave, and foamed in a water bath and a water bath with ultrasonic waves applied (ultrasonic power is 100W, ultrasonic frequency is 20kHz), the foaming temperature is 80°C, and the foaming time is 20s.

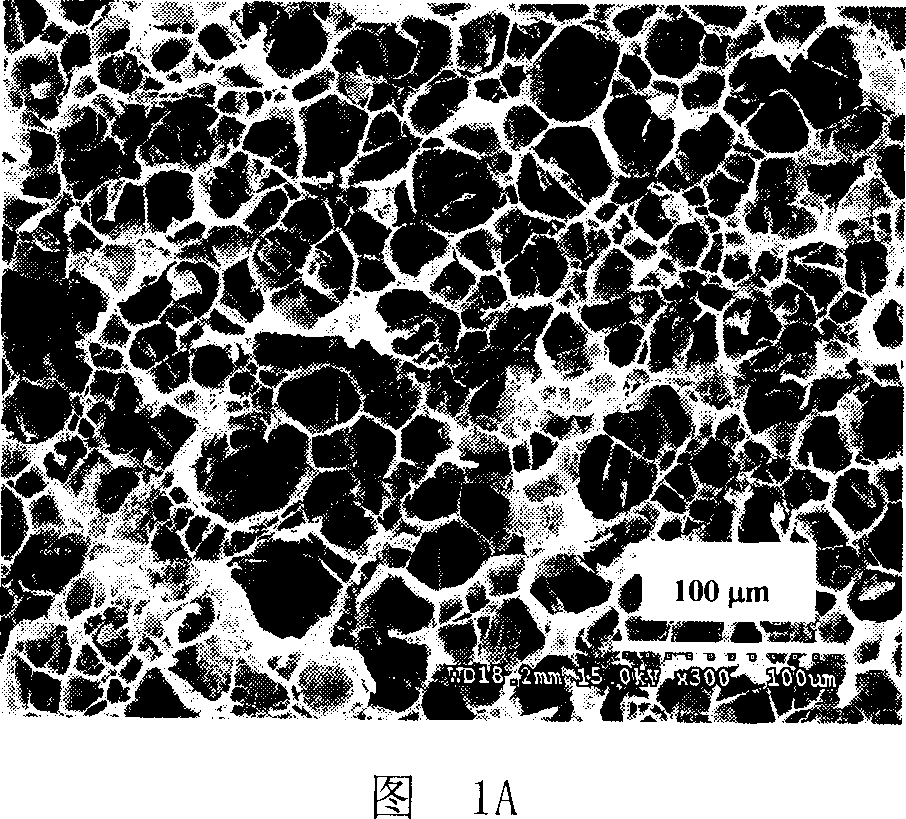

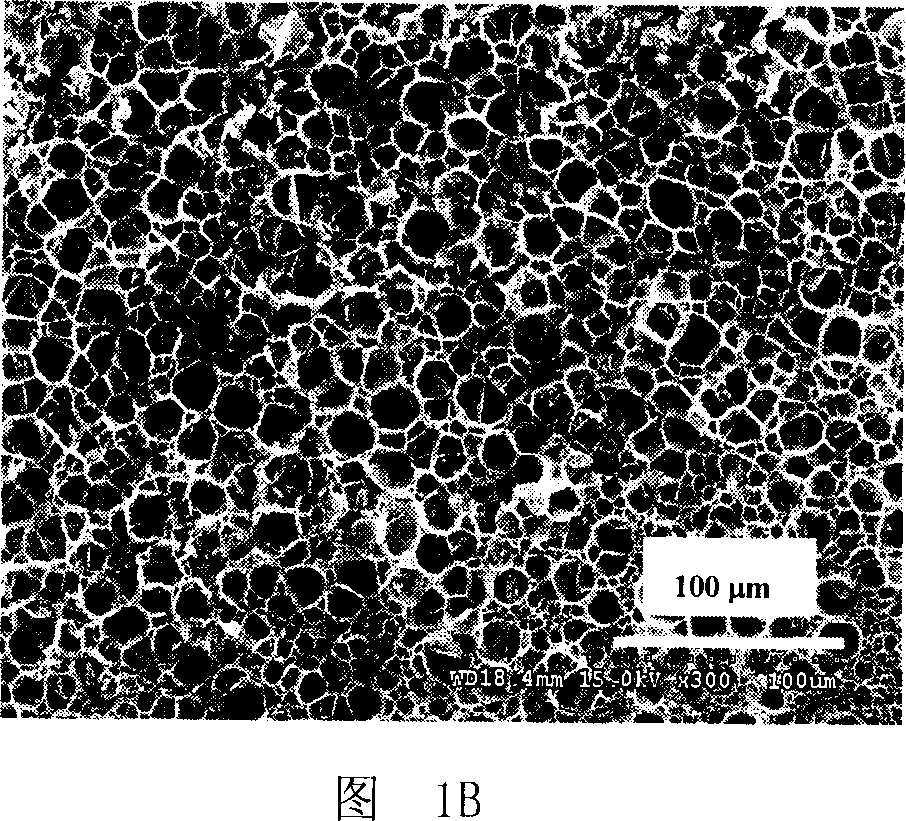

[0032] Figure 1A is an electron micrograph of the PMMA product section without ultrasonic waves, and Figure 1B is an electron microscopic photo of the PMMA product section with ultrasonic waves applied. The results show that after the ultrasonic waves are applied, the foaming ratio of the foamed PMMA increases from 2.3 without ultrasonic waves. to 4.6, the cell diameter is reduced from 14.0 μm to 4.2 μ...

Embodiment 2

[0033] Embodiment 2, the preparation of PS foamed product

[0034] The vacuum-dried polystyrene (PS) was heated to 200° C., kept for 3 minutes, and quenched in cold water to prepare a 1 mm thick sample.

[0035] The above PS sample was placed in an autoclave, and 40°C / 8MPa CO 2 After 6 hours of constant temperature and pressure, the sample was taken out of the autoclave, and foamed in a water bath and a water bath with ultrasonic waves (ultrasonic power 200W, ultrasonic frequency 20kHz), the foaming temperature was 80°C, and the foaming time was 20s.

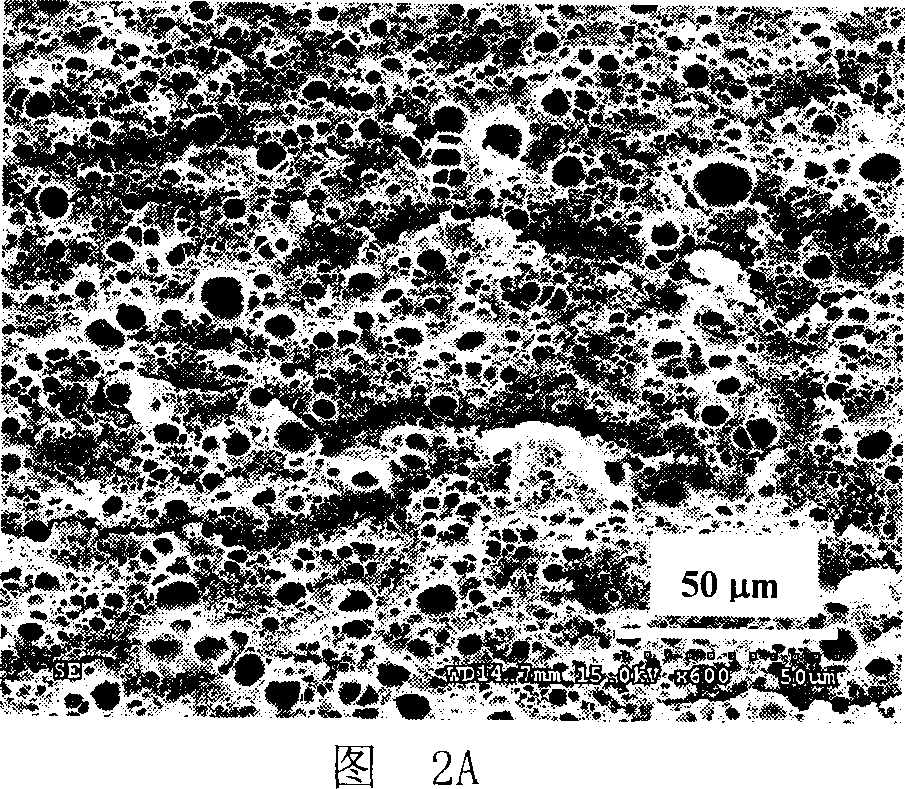

[0036] Figure 2A is an electron micrograph of the cross-section of PS products without ultrasonic waves, and Figure 2B is an electron microscopic photograph of the cross-sections of PS products with ultrasonic waves applied. The results show that after ultrasonic waves are applied, the foaming ratio of the foamed PS increases from 1.3 to 2.4, cell density from 7.5×10 10 cells / cm 3 Increased to 2.3×10 11 cells / cm 3 , the cel...

Embodiment 3

[0037] Embodiment 3, the preparation of PC foam product

[0038] The vacuum-dried polycarbonate (PC) was melted and pressed at 260° C., and quenched in cold water to prepare a 1 mm thick sample.

[0039] Put the above PC sample into an autoclave, and pass through CO at 20°C / 20MPa 2 After 10 hours of constant temperature and pressure, the sample was taken out from the autoclave, and foamed in a glycerin bath and a glycerin bath with ultrasonic waves (ultrasonic power 100W, ultrasonic frequency 20kHz), the foaming temperature was 100 ° C, and the foaming time was 30s.

[0040] Figure 3A is an electron micrograph of the PC product section without ultrasonic waves, and Figure 3B is an electron microscopic photo of the PC product section with ultrasonic waves applied. The results show that after ultrasonic waves are applied, the foaming ratio of the foamed PC increases from 1.1 without ultrasonic waves to 1.7, the cell diameter is reduced from 2.4 μm to 2.1 μm, and the cell densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell diameter | aaaaa | aaaaa |

| Cell density | aaaaa | aaaaa |

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com