Method for manufacturing purple corn anthocyanin

A manufacturing method and technology of purple corn, applied in the field of extracting anthocyanins, can solve problems such as waste of resources, achieve efficient extraction, simple operation process, and reduce degradation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

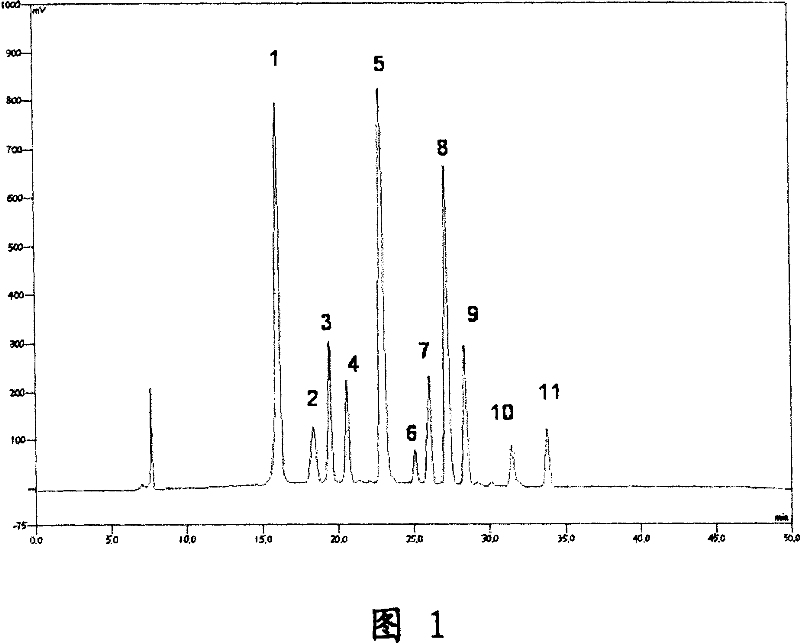

Image

Examples

Embodiment 1

[0032] The cobs of purple corn plants rich in anthocyanins are used as raw materials, and are dried with hot air under the condition of avoiding light, and the drying temperature is 45°C. The particle size of the dried materials after crushing is 50 mesh; then the materials are subjected to enzymatic hydrolysis treatment, The amount of water is preferably soaked in the material. The selected enzyme preparation is commercially available cellulase. The amount of the enzyme preparation is about 0.2% of the weight of the dry material. Adjust the pH value of the enzymolysis system to about 3; after the enzymolysis is completed, continue to add water and ethanol to the material to prepare an extraction system. The extractant in this system is ethanol aqueous solution, and the ethanol volume percentage is controlled at about 40%, An appropriate amount of citric acid is added to maintain an acidic extraction environment. The total amount of citric acid added is about 0.2% of the extrac...

Embodiment 2

[0038] Using fresh purple corn bracts as raw materials, firstly carry out enzymatic hydrolysis treatment on the material (properly dried), wherein the enzyme preparation used is a mixture of commercially available cellulase and hemicellulase, and the addition amount is about 0.8% of the weight of the leaf material (based on the content of cellulase), the reaction time is 50 minutes, the temperature is 50° C., and the pH of the enzymolysis system is adjusted to 3.5 by using citric acid. Carry out leaching after enzymatic hydrolysis, extractant is the ethanol aqueous solution of ethanol volume content 50%, is added with the citric acid of about 1% of extractant weight in the leaching system to maintain the acidic environment of leaching system, the material and extractant The ratio (material-to-liquid ratio) is 1:15; during the leaching process, ultrasonic-assisted extraction is used, and the power density of the ultrasonic wave is 1.2W / cm 2 , each ultrasonic treatment time is a...

Embodiment 3

[0042] Corn seed coats rich in anthocyanins are used as raw materials, and the seed coats are collected by corn seeds through a peeling machine. First, the raw materials are subjected to enzymatic hydrolysis treatment, and the selected enzyme is a mixture of commercially available cellulase and hemicellulase , the addition ratio of the enzyme preparation is 2% of the weight of the corn seed coat raw material, the reaction time is 15 minutes, the temperature is 60° C., and the pH is adjusted to 5 by citric acid. Add ethanol to the material after enzymatic hydrolysis to form an ethanol aqueous solution with an ethanol volume content of about 80% as an extractant for extraction. The ratio of solid to liquid is about 1:10, and about 1% by weight of the extractant is added to the extraction system of citric acid (to maintain the pH4 of the extraction system). The extraction process uses ultrasonic-assisted extraction, and the power density of the ultrasonic wave is 1W / cm 2, each u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com