Method for producing food level liquid carbon dioxide product

A liquid carbon dioxide and production method technology, applied in chemical instruments and methods, food preparation, inorganic chemistry, etc., can solve the problems of high energy consumption, low recovery rate, and difficult liquefaction, etc., to reduce energy consumption and reduce external heat sources , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

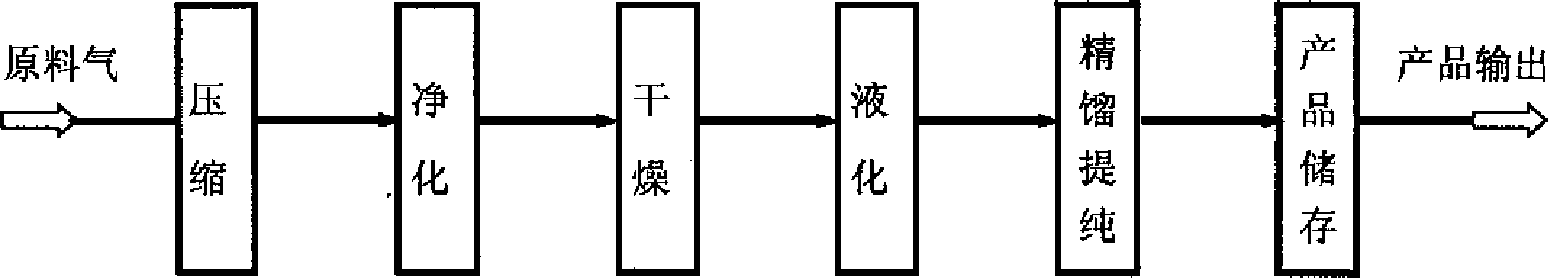

Method used

Image

Examples

Embodiment Construction

[0023] 1. Raw gas compression

[0024] According to the raw material gas, the carbon dioxide-rich raw gas sent from outside the boundary area is washed and pre-cooled, and the mechanical water is removed by the water separator, and then enters the raw gas compressor, and is compressed to 2.0-3.0MPa by three stages. A small part of the raw gas from the third stage of the compressor is sent to the purification tower of the condensation purification process as the heat source of the reboiler, and most of the gas is cooled by the aftercooler at the third stage of the compressor, and then sent to the oil removal and purification process.

[0025] The distribution of the gas at the third-stage outlet of the compressor is adjusted by the regulating valve, so that the compressed gas delivered to the purification tower can fully provide the heat source required for fractionation and purification. This is one of the characteristics of the present invention. Certainly also can adopt oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com