Method for preparation of multifarious Sb2O3 nanostructure

A nanostructure and nanotechnology, which is applied in the field of high-temperature reduction of ATO nanoparticles to prepare various Sb2O3 nanostructures, can solve the problems of complex operation process, high production cost, and various drugs, and achieve simple process flow, good crystallization performance, and product shape. various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1. Sb 2 o 3 Preparation of branched structures

[0050] 3g of ATO nanoparticles and graphite powder mixture with a mass ratio of 6:1 was ground for half an hour and placed in a ceramic boat, and the ceramic boat was placed in the middle of the ceramic tube, and the Si sheet was placed downstream at a distance of 13 cm from the original position of the mixed powder. Before heating, pass high-purity Ar at a flow rate of 200 sccm into the system for 2 hours to exhaust the air in the system; then adjust the Ar flow rate to 100 sccm, start the tube furnace, and wait for the system to rapidly heat up to 1200°C (about 10 minutes) , the flow rate of 1sccm oxygen was introduced into the system, and the system began to cool down after 2 hours. At this time, the flow rate of Ar was kept constant, and the oxygen was turned off. After the system was naturally cooled to room temperature, the Si sheet was taken out.

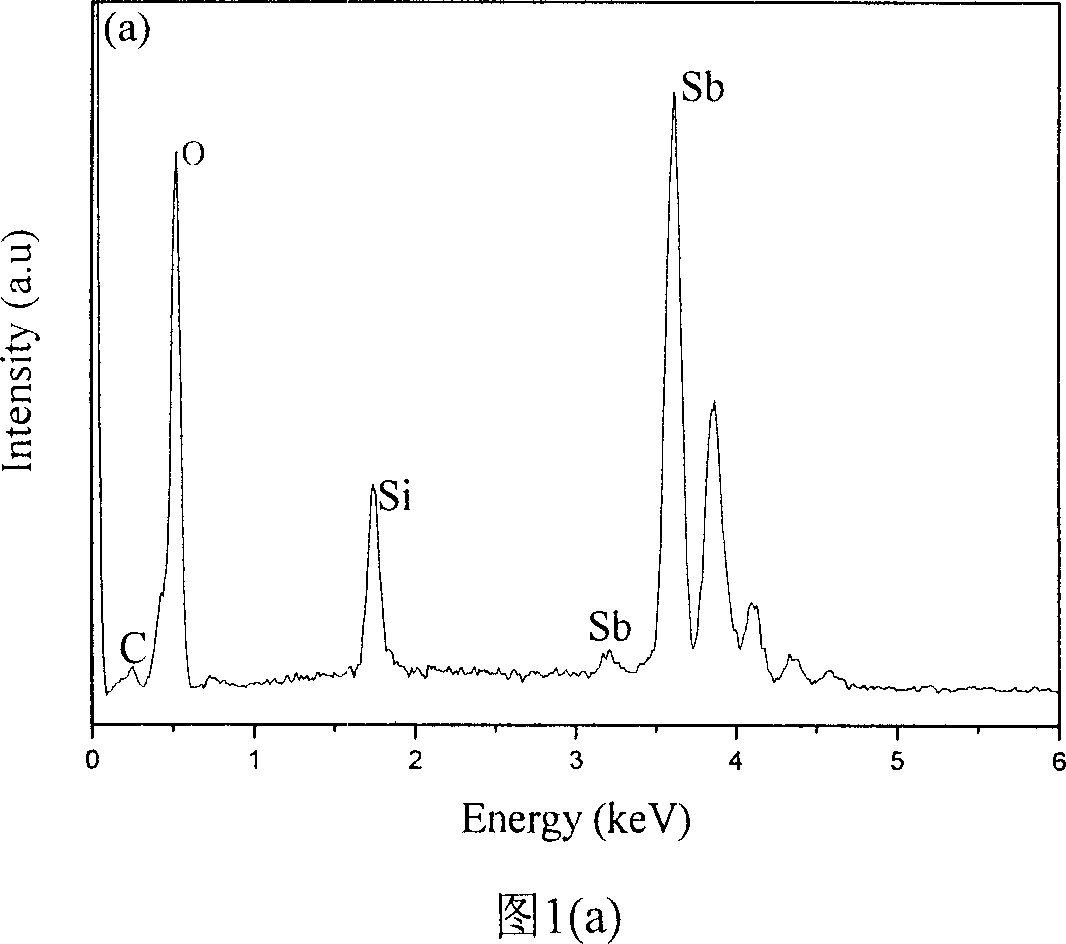

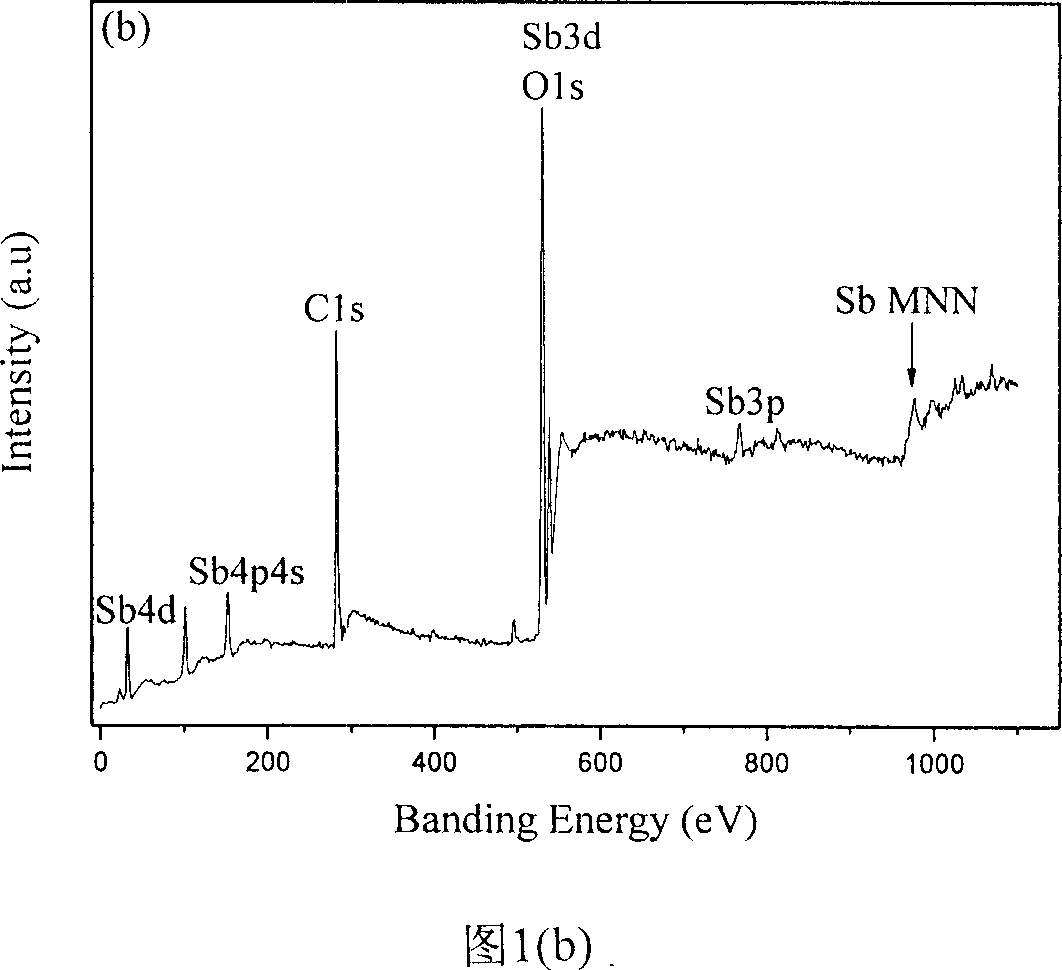

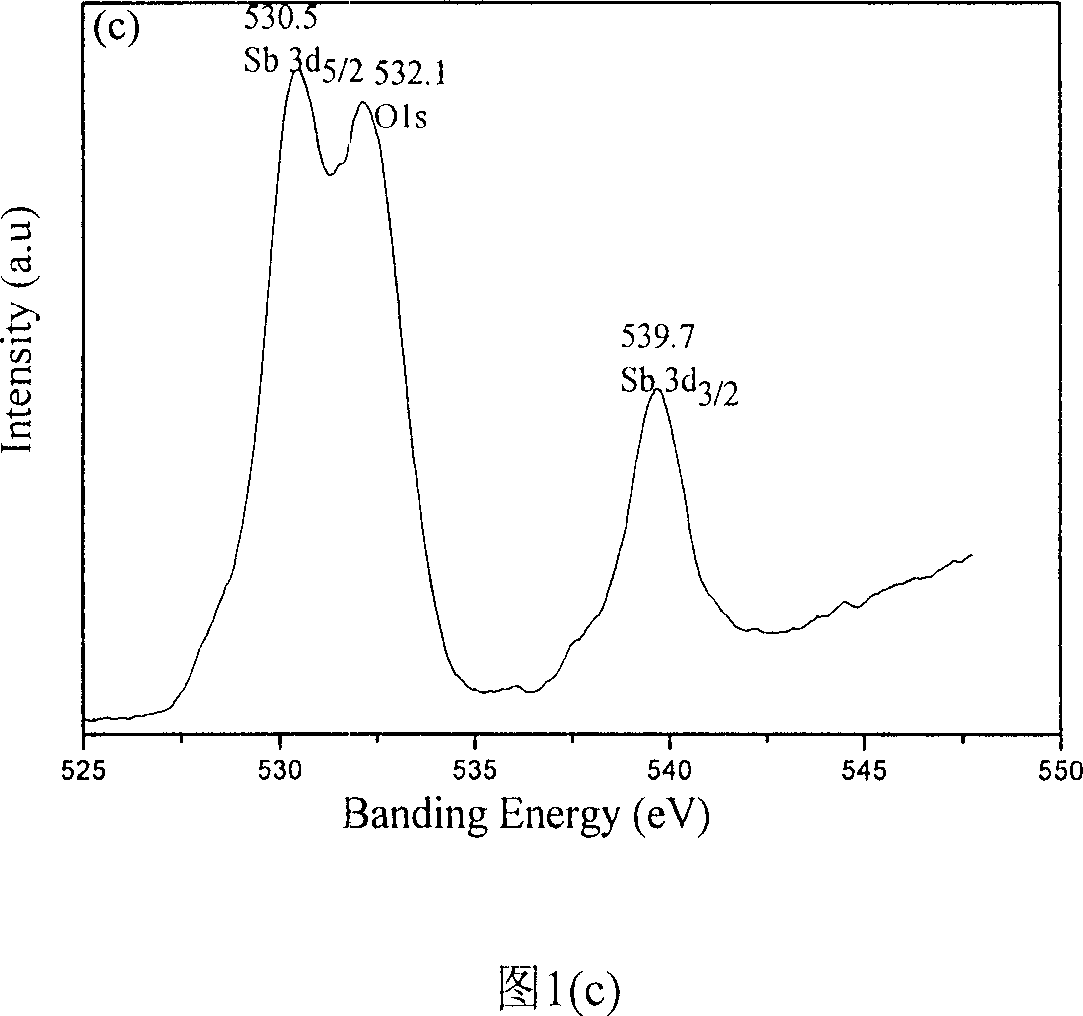

[0051] Its composition was investigated by electron spect...

Embodiment 2

[0052] Example 2. Sb 2 o 3 Fabrication of Nanorod Arrays

[0053] 3g of ATO nanoparticles and activated carbon mixture with a mass ratio of 4:1 was ground for half an hour and placed in a ceramic boat, and the ceramic boat was placed in the middle of the ceramic tube, and the Si sheet was placed downstream at a distance of 13 cm from the original position of the drug. Before heating, feed high-purity Ar2h with a flow rate of 200 sccm into the system to exhaust the air in the system; then adjust the Ar flow rate to 80 sccm, start the tube furnace, and wait for the system to rapidly heat up to 1150°C (about 10min). Introduce oxygen with a flow rate of 1 sccm into the system, and the system starts to cool down after 1.5 hours. At this time, keep the flow rate of Ar constant, turn off the oxygen, and take out the Si sheet after the system is naturally cooled to room temperature.

[0054] Its composition was investigated by electron spectroscopy (EDS) and X-ray photoelectron spec...

Embodiment 3

[0055] Example 3. Sb 2 o 3 Preparation of nanorods

[0056] 3 g of ATO nanoparticles and activated carbon mixture with a mass ratio of 2:1 were ground for half an hour and placed in a ceramic boat, and the ceramic boat was placed in the middle of the ceramic tube, and the Si sheet was placed downstream at a distance of 13 cm from the original position of the drug. Before heating, first pass high-purity Ar2h with a flow rate of 200 sccm into the system to exhaust the air in the system; then adjust the Ar flow rate to 50 sccm, start the tube furnace, and wait for the system to rapidly heat up to 1150°C (about 10min). Introduce oxygen with a flow rate of 1 sccm into the system, and the system starts to cool down after 1 hour. At this time, keep the flow rate of Ar constant, turn off the oxygen, and take out the Si sheet after the system is naturally cooled to room temperature.

[0057] Its composition was investigated by electron spectroscopy (EDS) and X-ray photoelectron spect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com