Varistor with novel short-circuit protection device

A technology of short-circuit protection and varistor, applied in the direction of varistor, current response resistor, etc., can solve the problems of complex structure, poor shock resistance, slow heat conduction, etc., and achieve the effect of complex structure, poor shock resistance and high inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

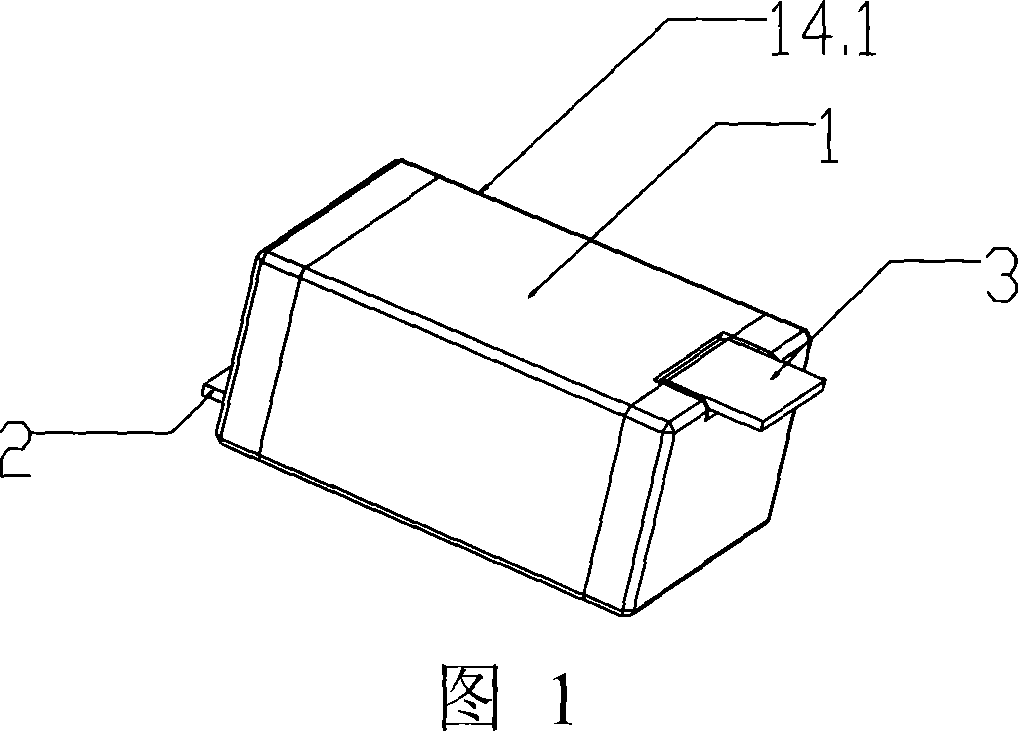

[0075] See Figure 1

[0076] Fig. 1 is a perspective view of a novel short-circuit protection device in the present invention. In Fig. 1, described a kind of piezoresistor 14 with novel short-circuit protection device 14.1 comprises insulator matrix 1, and electrode 2 and electrode 3 protrude from two ends in the body 1 of short-circuit protection device 14.1 respectively, and described electrode 3 has The function of heat transfer, conduction and fixed short-circuit protection device 14.1, the electrode 2 is used to connect with the lead-out pin 13 of the piezoresistor 14 (as shown in FIG. 4 ).

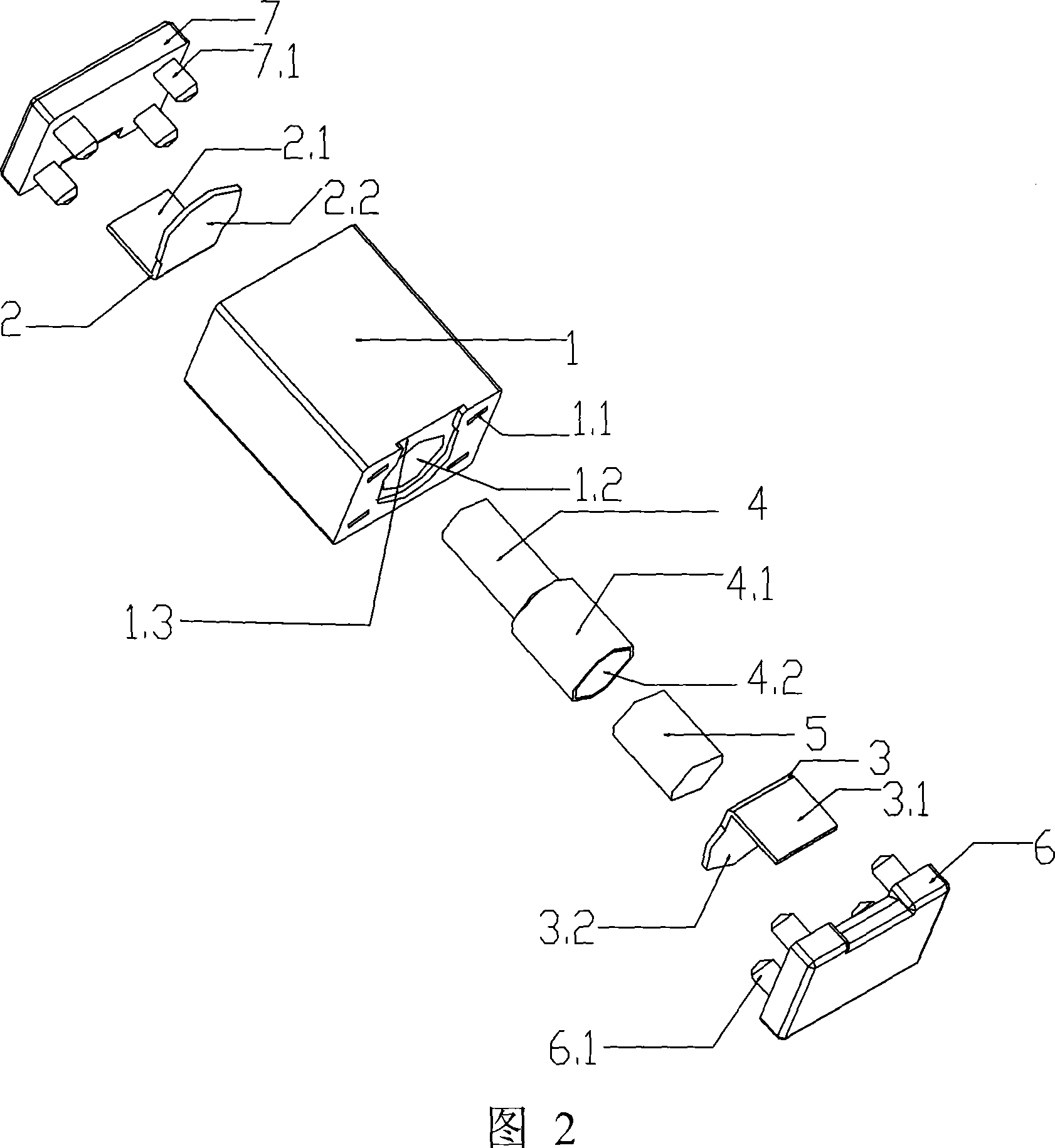

[0077] See Figure 2

[0078] Fig. 2 is an assembly drawing of parts of the novel short-circuit protection device of the present invention. In Fig. 2, the insulator matrix 1 and the insulator outer covers 6, 7 of the novel short protection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com