Method for extracting buckwheat flavone from buckwheat shell

A technology for buckwheat flavonoids and buckwheat hulls is applied in the field of preparation of non-alcoholic beverages, and can solve the problems that sodium carbonate has not been found to extract buckwheat flavonoids or rutin, and there is no buckwheat flavonoids or rutin. high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

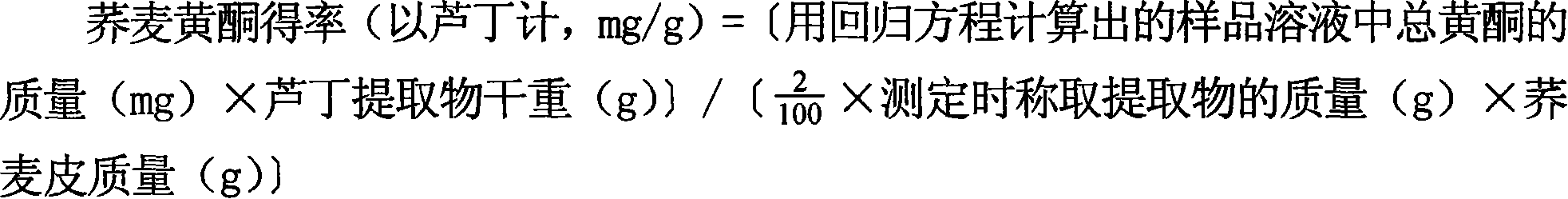

Method used

Image

Examples

Embodiment 1

[0022] Take the 50g sweet buckwheat husk raw material as an example, other raw materials used and the preparation process steps are as follows:

[0023] 1. Take 50 g of sweet buckwheat husks, dry them at 60° C., grind them to a particle size of 0.3 mm, and prepare buckwheat husk powder.

[0024] 2. Sodium carbonate is prepared with pure water to make a sodium carbonate aqueous solution with a concentration of 0.1mol / L.

[0025] 3. Put the buckwheat husk powder into the ultrasonic extractor, add 400 g of sodium carbonate aqueous solution with a concentration of 0.1mol / L, let it stand for 10 minutes, add 600 g of pure water, that is, buckwheat husk powder: 0.1mol / L sodium carbonate solution: The weight ratio of pure water is 1:8:12, the frequency is 40kHz, and the power is 0.4W / cm 2 Ultrasonic extraction, the extraction temperature is 40 ° C, the extraction time is 20 minutes, and the extract is taken out. In residue, adding concentration is 200g of sodium carbonate aqueous so...

Embodiment 2

[0032] Take the 50g sweet buckwheat husk raw material as an example, other raw materials used and the preparation process steps are as follows:

[0033] In the process step 1, sweet buckwheat husks are crushed to a particle size of 0.21 mm to prepare buckwheat husk powder. In process step 3, buckwheat husk powder is put into the ultrasonic extractor, adding concentration is 300g of sodium carbonate aqueous solution of 0.1mol / L, standing for 10 minutes, adding 450g of pure water, buckwheat husk powder: 0.1mol / L of carbonic acid The weight ratio of sodium solution: pure water is 1:6:9, the frequency is 40kHz, and the power is 0.3W / cm 2 Ultrasonic extraction, the extraction temperature is 50 ° C, the extraction time is 30 minutes, and the extract is taken out. In residue, adding concentration is 200g of sodium carbonate aqueous solution of 0.1mol / L, leave standstill 10 minutes, add pure water 300g, the sodium carbonate solution of buckwheat flour: 0.1mol / L: the weight ratio of p...

Embodiment 3

[0035] Take the 50g sweet buckwheat husk raw material as an example, other raw materials used and the preparation process steps are as follows:

[0036] In process step 1, sweet buckwheat husks are crushed to a particle size of 0.59 mm to prepare buckwheat husk powder. In process step 3, buckwheat husk powder is loaded into the ultrasonic extractor, adding concentration is 600g of sodium carbonate aqueous solution of 0.1mol / L, standing for 10 minutes, adding pure water 900g, buckwheat husk powder: 0.1mol / L carbonic acid The weight ratio of sodium solution: pure water is 1:12:18, the frequency is 40kHz, and the power is 0.5W / cm 2Ultrasonic extraction, the extraction temperature is 30 ° C, the extraction time is 15 minutes, and the extract is taken out. In residue, adding concentration is 200g of sodium carbonate aqueous solution of 0.1mol / L, leave standstill 10 minutes, add pure water 300g, the sodium carbonate solution of buckwheat flour: 0.1mol / L: the weight ratio of pure wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Grinding particle size | aaaaa | aaaaa |

| Grinding particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com