High DNA type fatty ethyl ester in high purity, manufacturing method and preparation

The technology of a fatty acid ethyl ester and its manufacturing method is applied in the field of preparations for the treatment or prevention of hyperlipidemia, angina pectoris and cerebral infarction, which can solve the problems of lack of practicability and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

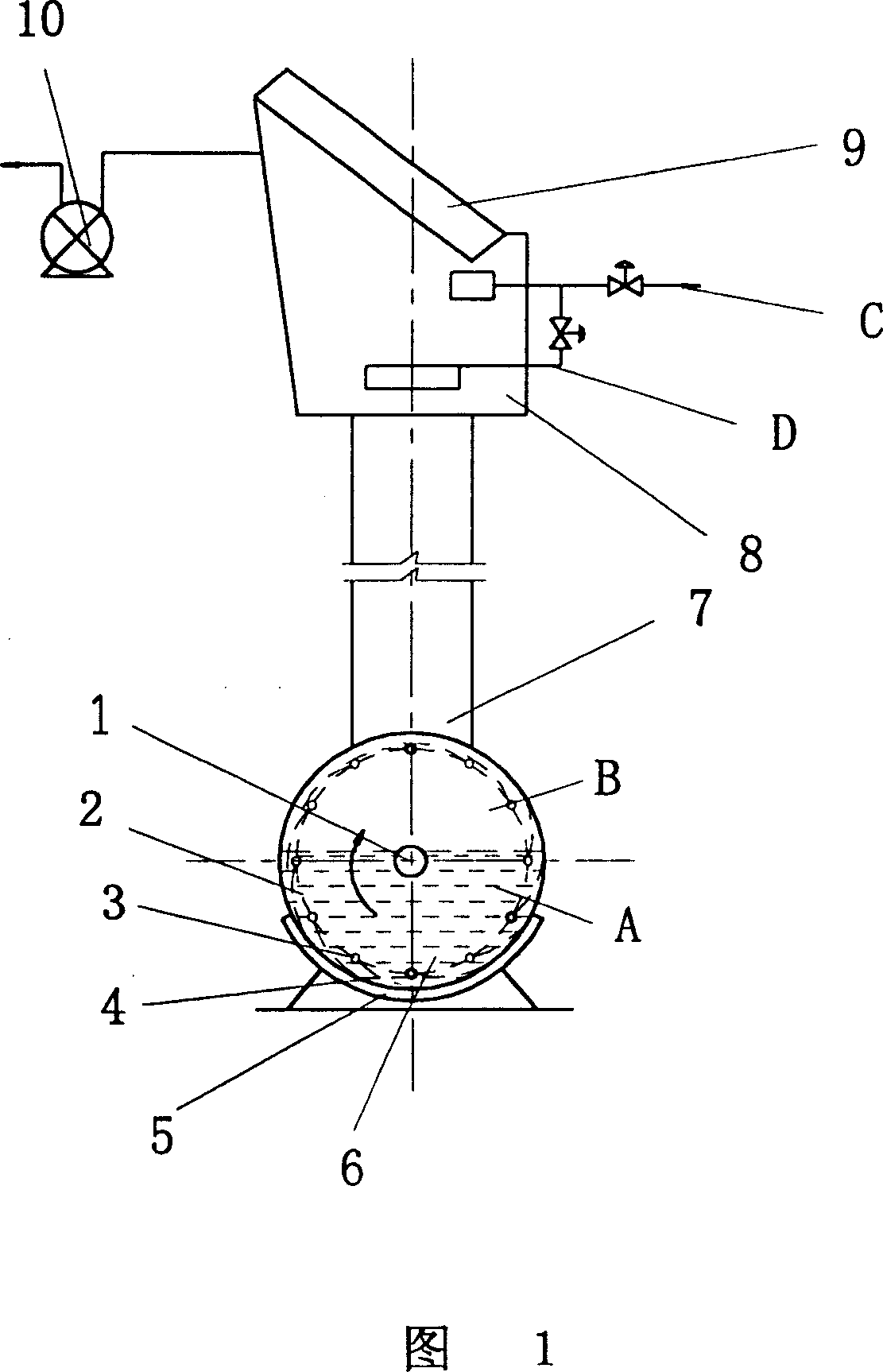

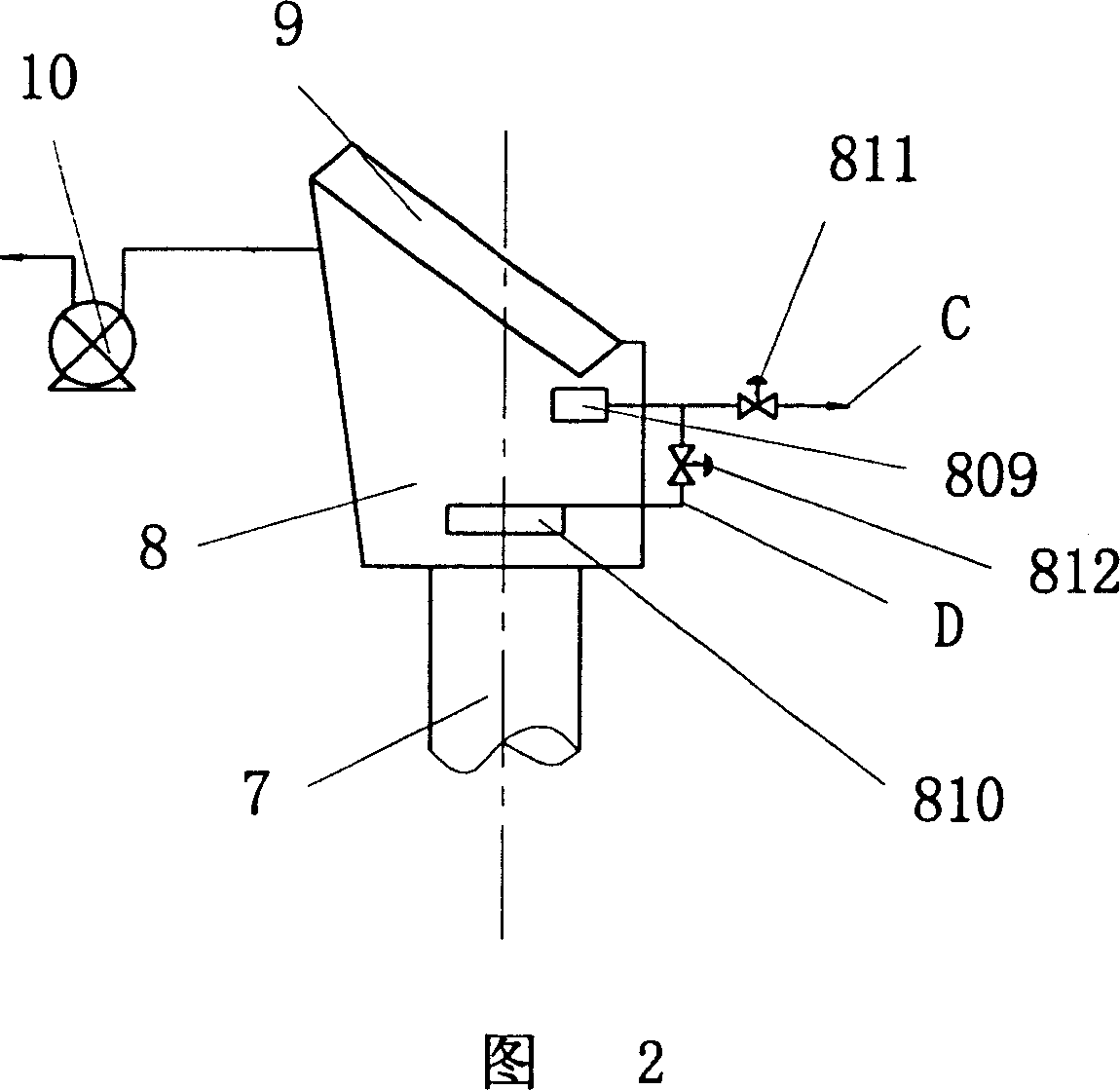

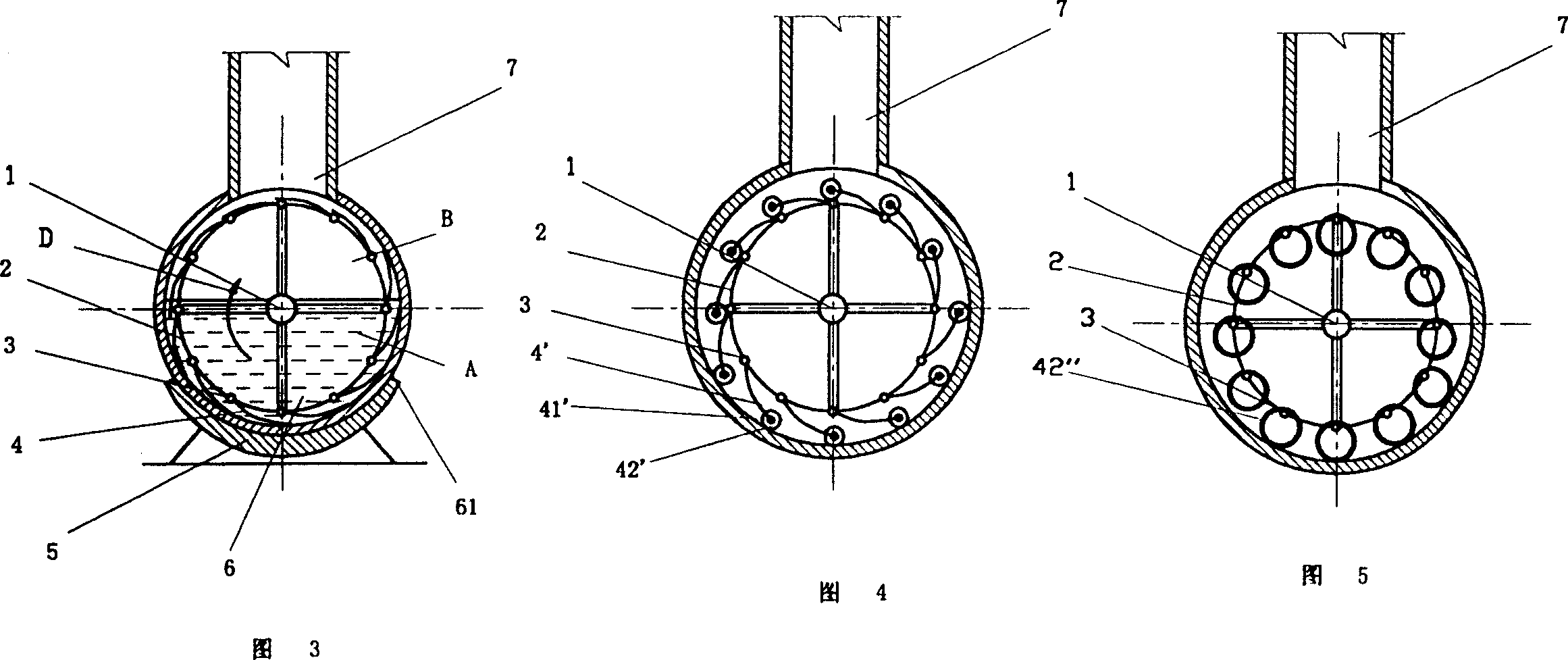

Image

Examples

Embodiment 1

[0044] The preparation method of high DHA-E type provided by the invention, EPA-E and DHA-E high-purity fatty acid ethyl ester is:

[0045] First, the fish oil whose total amount of EPA-E and DHA-E is about 25% by weight is ethyl-esterified, and then the ethyl-esterified fish oil ethyl ester is pretreated by the conventional urea inclusion method, the process of the urea inclusion method for existing technology. The process can adopt the urea inclusion method disclosed in the article (Author: Li Guowen, etc.) published in the first issue of "Agricultural Engineering Journal" in March, 1997 "Research on the Preconcentration of Fish Oil Physiologically Active Components by Urea Inclusion Method". Or adopt the technology in the "Research on the Enrichment of EPA and DHA in Fish Oil by Urea Inclusion Method" published in the fifth issue of volume 22 of "China Oils and Fats" in 1997. After treatment, the content of EPA-E and DHA-E in the fish oil ethyl ester is increased to 74.3% ...

Embodiment 2

[0062] The same medium-content raw material 100Kg obtained by pretreatment in the same way as in Example 1 is added to the volatilization still of the same vacuum distillation tower as in Example 1 for rectification. The structure of its vacuum film-attached volatilization device is the same as that of Example 1. The specific operating conditions are as follows: the rotational speed of the main shaft is 60 rpm, the number of trays is 4, and corrugated wire mesh packing is used. The temperature at the bottom of the tower is 160-180°C, the temperature at the top of the tower is 55-100°C, the degree of vacuum is 8-12Pa, the reflux ratio is 0.6:1, and the rectification time is 28 hours.

[0063] Rectification obtains 56Kg product, wherein the total content of (EPA-E) and (DHA-E) accounts for 84.72% by weight of product total amount, and the weight ratio of (EPA-E) and (DHA-E) is 1: 1.86 , becoming a high-purity fatty acid ethyl ester product of high DHA-E type.

Embodiment 3

[0065] 100 kilograms of the same middle-content raw material that pretreatment obtains by the same method of embodiment 1 adds in the volatilization kettle of the vacuum rectification column identical with embodiment 1 and carries out rectification, and the implementation structure of vacuum attached film volatilization device is the same as embodiment 1, The specific operating conditions are as follows: the rotating speed of the main shaft is 100 rpm, the number of trays is 2, and corrugated packing with rolled orifice is used. The temperature at the bottom of the tower is 170-185°C, the temperature at the top of the tower is 65-110°C, the degree of vacuum is 3-8Pa, the reflux ratio is 1:1, and the rectification time is 30 hours.

[0066] Rectification obtains 60 kilograms of products, wherein (EPA-E) and (DHA-E) total content account for the weight percent of product total amount and be 82.44%, (EPA-E) and (DHA-E) weight ratio are 1: 1.09 , becoming a high-purity fatty acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com