Surface modified coat of bracket of blood vessel, and preparation method

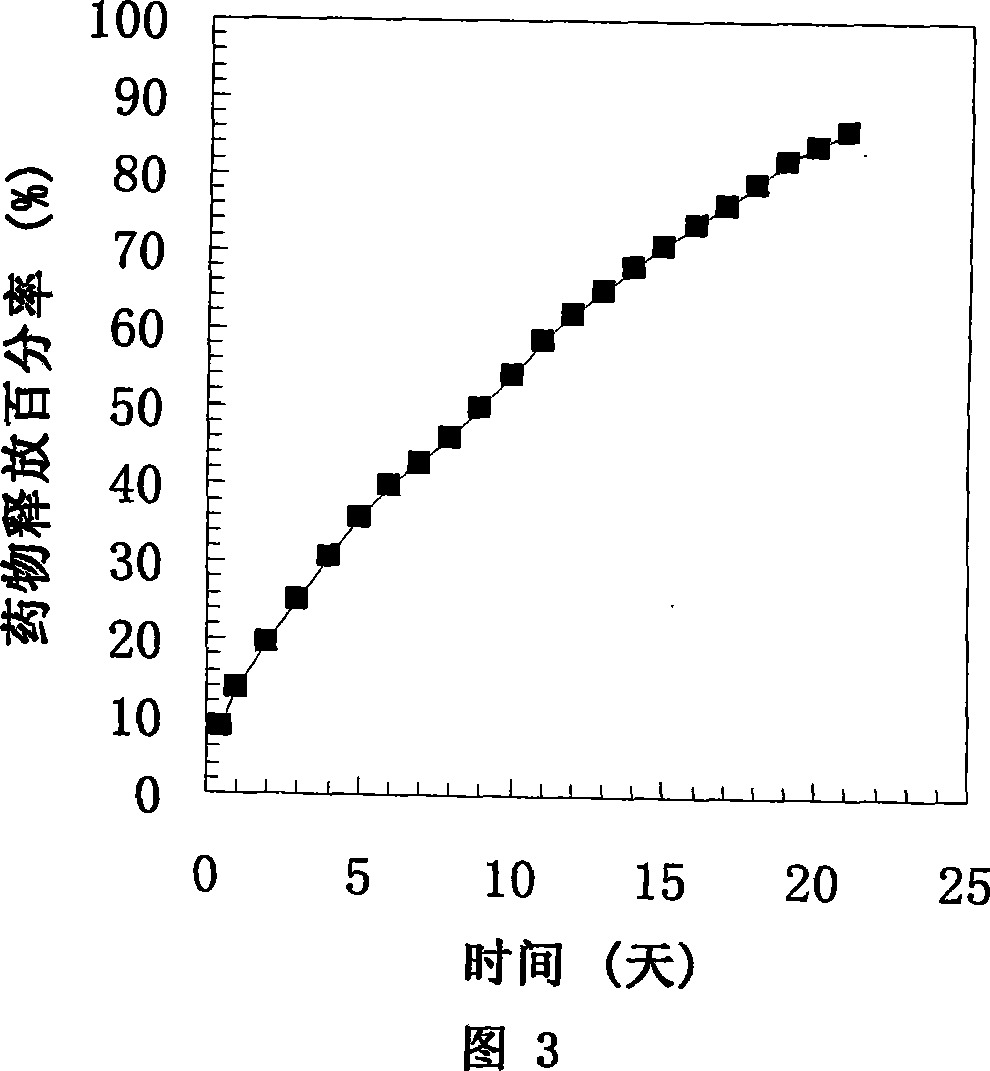

A vascular stent and surface modification technology, applied in the coating and other directions, can solve the problems of local inflammatory reaction and vascular occlusion caused by degradation products, and achieve the effect of large application value, smooth drug release rate and uniform coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Cleaning of the stent: Put the stent in acetone for 20 minutes for ultrasonic cleaning, then put it in hot water at 60-100 degrees Celsius for 20 minutes, then put it in medical disinfectant alcohol for 10 minutes, and finally take it out and dry it for later use.

[0044] 2) Preparation of coating solution: measure 15 milliliters of tetrahydrofuran and put it into a stoppered flask, then weigh 560 mg of polysulfone-polyoxyethylene block copolymer with a polyethylene oxide content of 35%, stopper the bottle tightly, and fix Shake on a shaker for 20-60 minutes until the copolymer is completely dissolved.

[0045] 3) Fix one end of the cleaned bracket on the rotating shaft of the stepper motor capable of rotating and moving back and forth.

[0046] 4) The syringe pump draws the solution prepared in step 2), atomizes it with an ultrasonic nozzle, and then coats it on the surface of the stent. Utilize the reciprocating movement of the support to complete its 10 spraying...

Embodiment 2

[0050] 1) Cleaning of the stent: Put the stent in acetone for 20 minutes for ultrasonic cleaning, then put it in hot water at 60-100 degrees Celsius for 20 minutes, then put it in medical disinfectant alcohol for 10 minutes, and finally take it out and dry it for later use.

[0051] 2) Preparation of the coating solution: measure 15 milliliters of tetrahydrofuran and put it into a stoppered flask, then weigh 600 mg of polysulfone-polyoxyethylene block copolymer with a polyethylene oxide content of 35%, stopper the bottle tightly, and fix Shake on a shaker for 20-60 minutes until the copolymer is completely dissolved; add 200 mg of drug rapamycin to the solution, then shake on a shaker until dissolved.

[0052] 3) Fix one end of the cleaned bracket on the rotating shaft of the stepper motor capable of rotating and moving back and forth.

[0053] 4) The syringe pump draws the solution prepared in step 2), atomizes it with an ultrasonic nozzle, and then coats it on the surface of...

Embodiment 3

[0057] 1) Cleaning of the stent: Put the stent in acetone for 20 minutes for ultrasonic cleaning, then put it in hot water at 60-100 degrees Celsius for 20 minutes, then put it in medical disinfectant alcohol for 10 minutes, and finally take it out and dry it for later use.

[0058] 2) Preparation of coating solution: measure 15 milliliters of tetrahydrofuran and put it into a stoppered flask, then weigh 500 mg of polysulfone-polyoxyethylene block copolymer with a polyethylene oxide content of 45%, stopper the bottle tightly, and fix Shake on a shaker for 20-60 minutes until the copolymer is completely dissolved; add 150 mg of ligustrazine to the solution and shake it on a shaker until dissolved.

[0059] 3) Fix one end of the cleaned bracket on the rotating shaft of the stepper motor capable of rotating and moving back and forth.

[0060] 4) The syringe pump draws the solution prepared in step 2), atomizes it with an ultrasonic nozzle, and then coats it on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com