Highly efficient treatment process for waster water with high content of salt

A treatment process, high salt content technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problem of poor resistance to salinity impact, long-term guarantee of treatment effect, Low efficiency and other problems, to achieve the effect of improving the ability to resist salinity shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

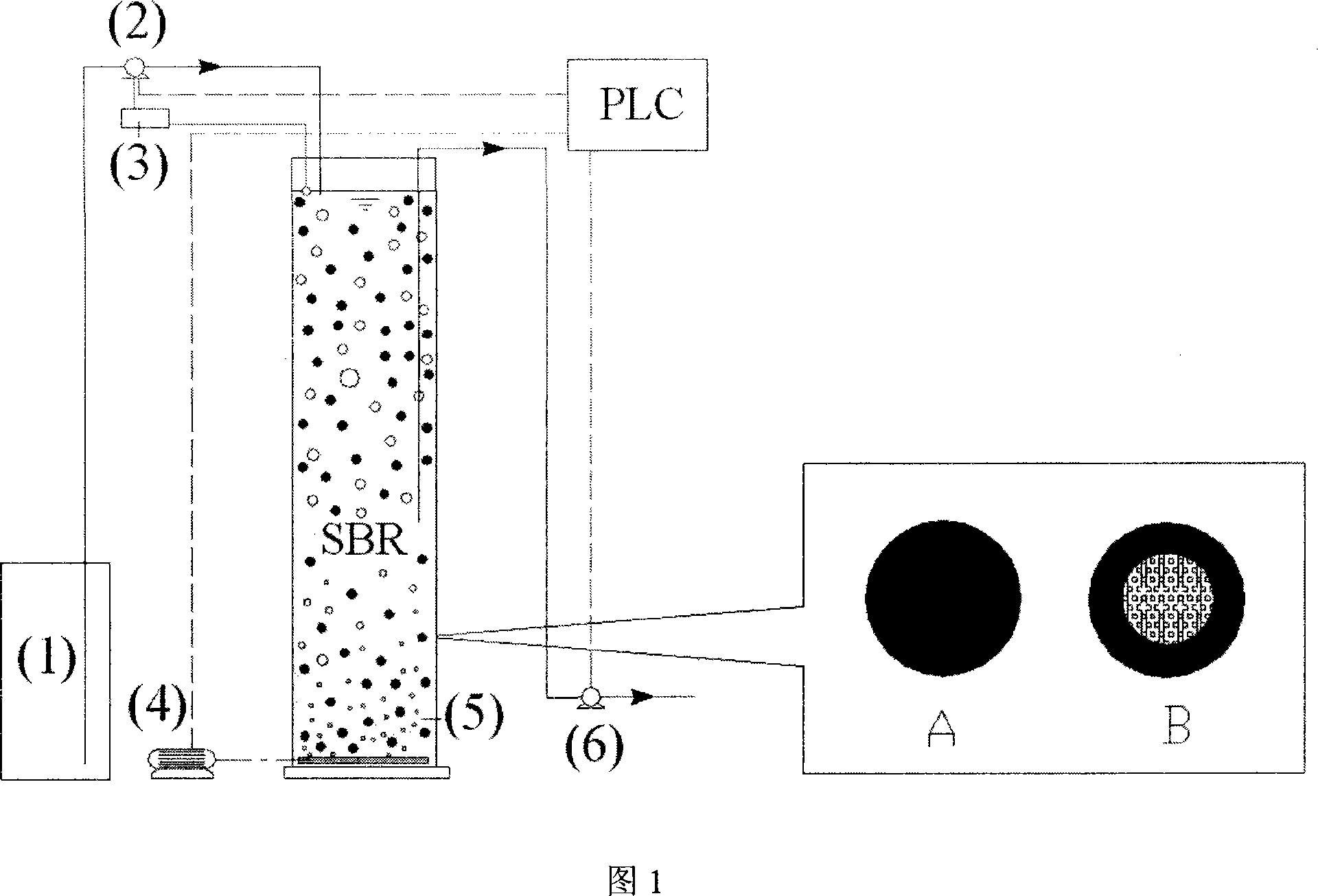

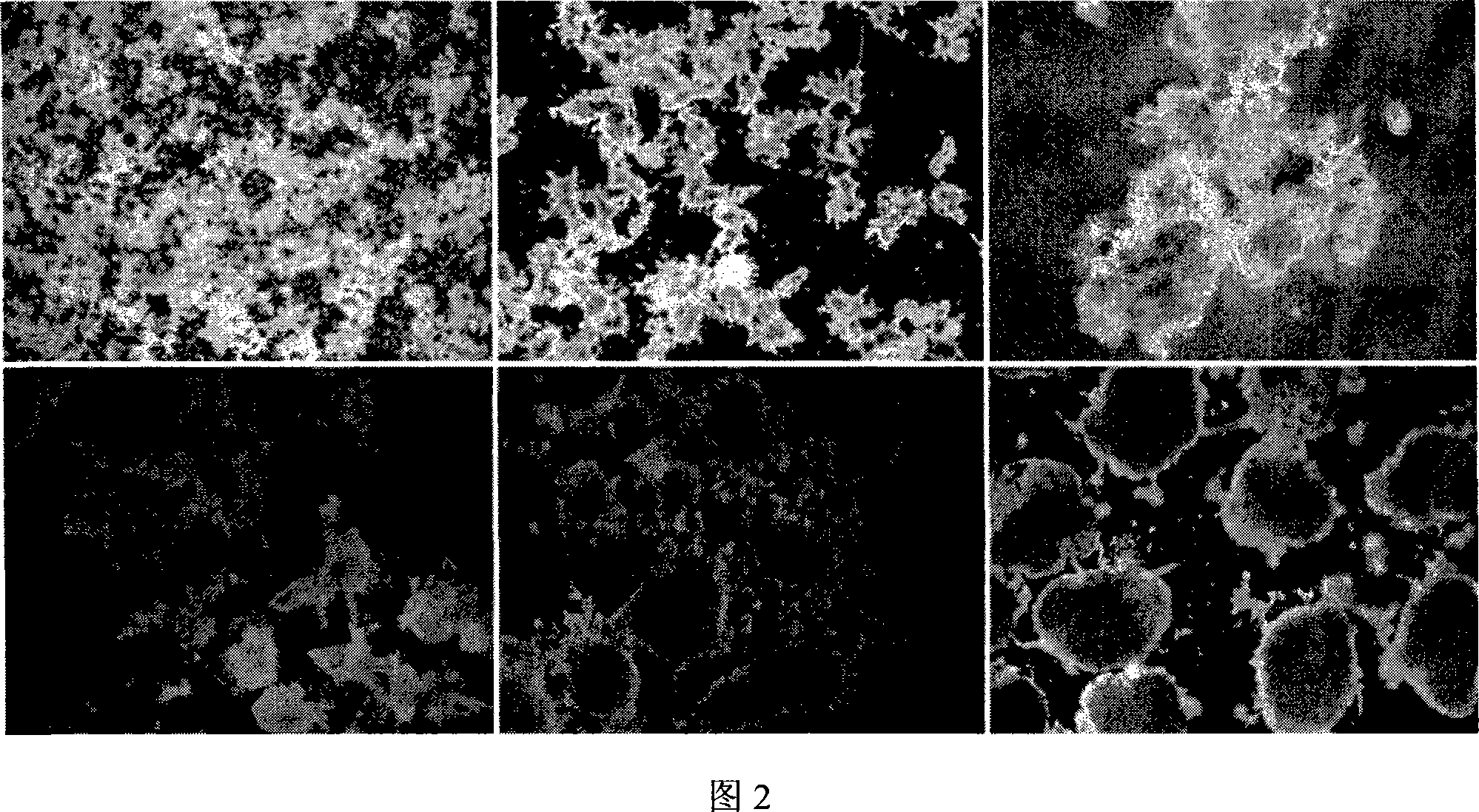

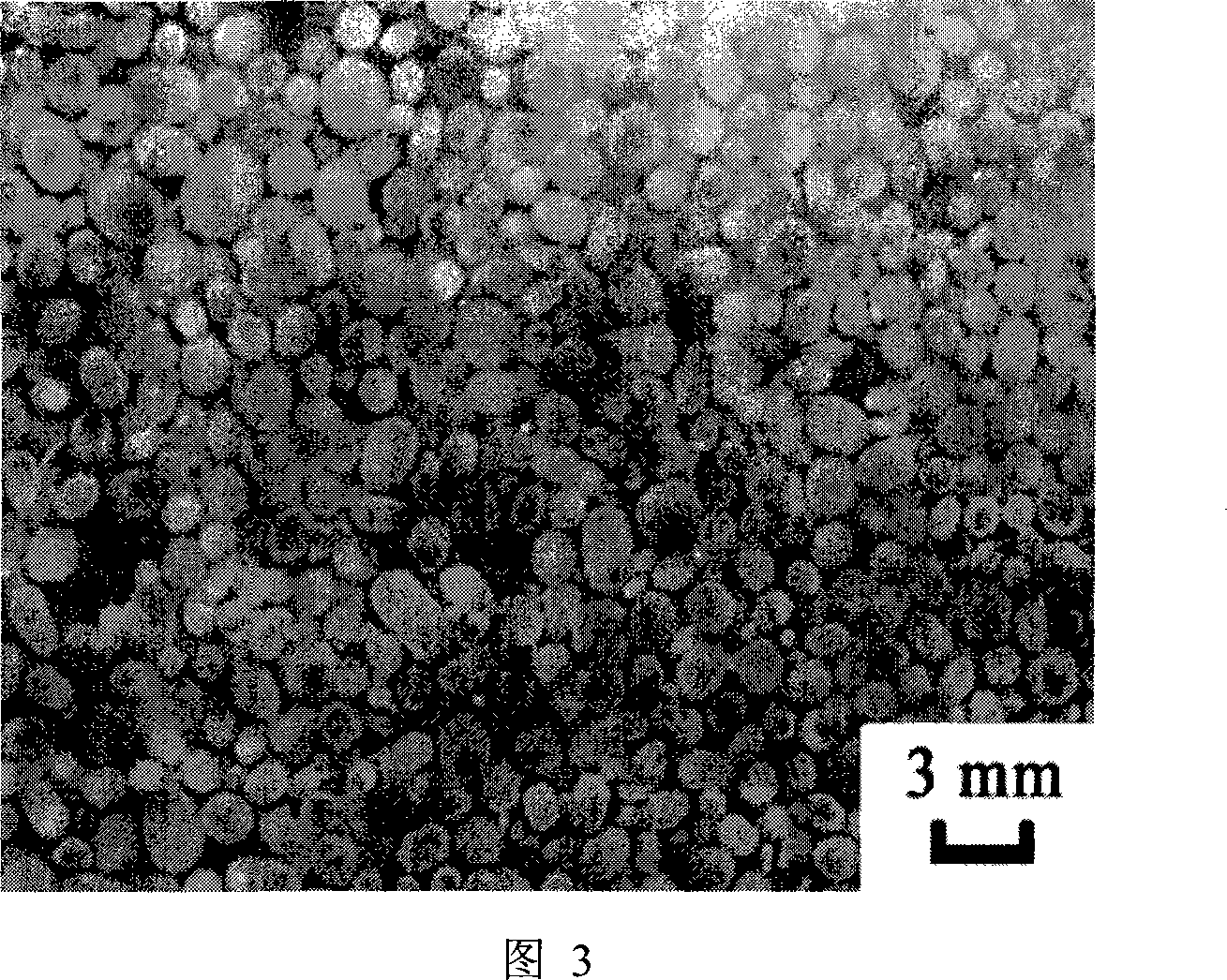

[0011] Figure 1 is an enlarged schematic diagram of the aerobic granular sludge formed in the high-saline wastewater treatment device and its reactor. During the start-up period of the system shown in the figure, gradually increase the salinity of the influent. When the salinity is less than 10g / LNaCl, the gradient of each salinity change is 2g / LNaCl, and at least 8 cycles are run under each salinity condition. The aerobic sludge granulation control in the treatment system is realized under the condition that the salinity is less than 10g / LNaCl, and the granulation degree is more than 75%. When better sludge granulation is achieved in the reactor and the salinity reaches 10g / LNaCl, the gradient of each salinity increase gradually changes to 3g / LNaCl and 4g / LNaCl, and when the salinity reaches 30g / LNaCl, the salinity changes The gradient is 5g / L NaCl. The start-up period ends after the aerobic granular sludge cultivation and domestication in high-salt wastewater is achieved s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com