Fluid regulation type internal insulation structure and its prefabricated method

A regulating and fluid technology, applied in thermal insulation, building components, heating methods, etc., can solve the problems of difficult cooling and cooling methods, difficult to popularize and implement, long construction period, etc., and achieve significant energy saving effect, simple structure, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

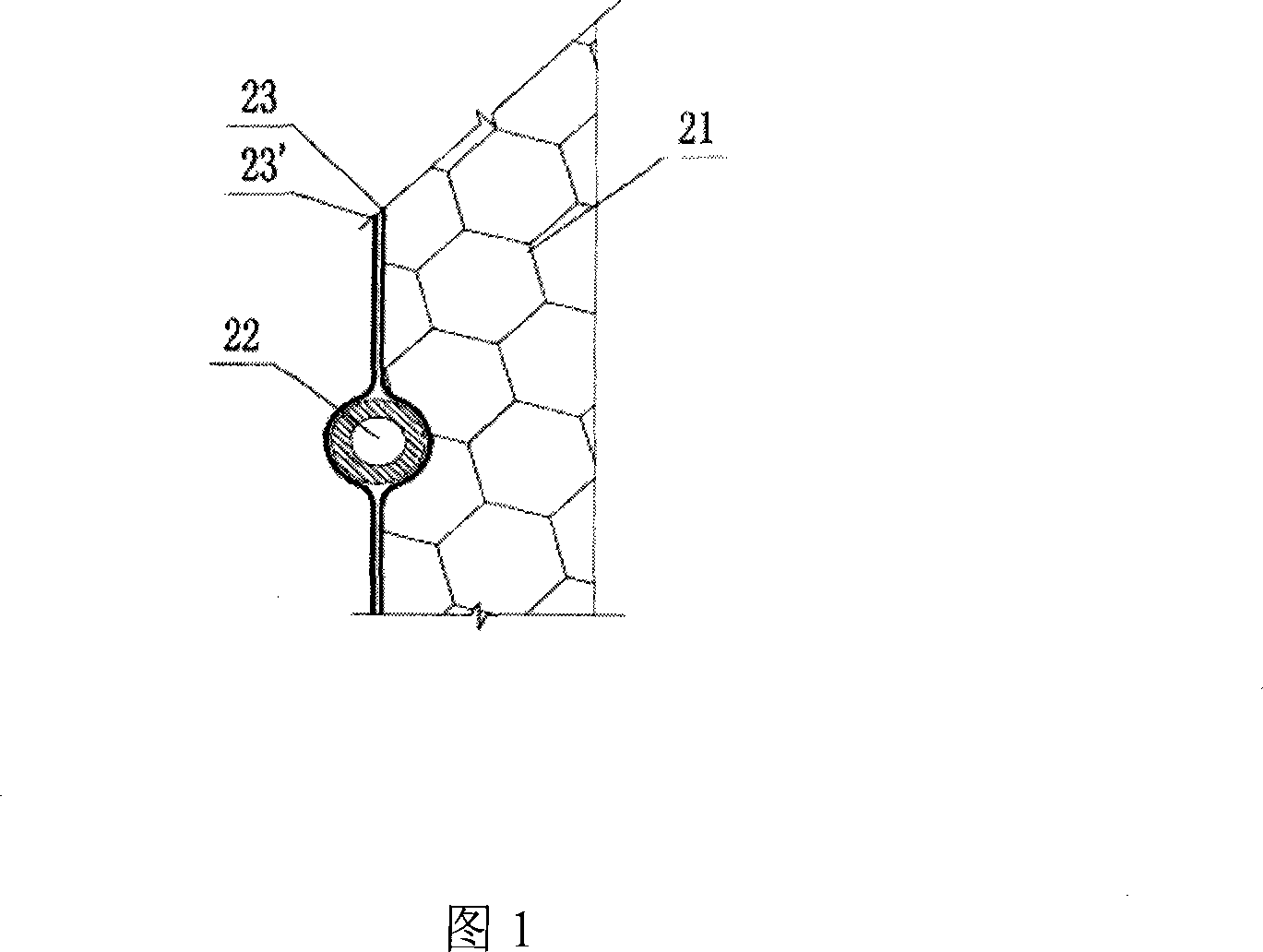

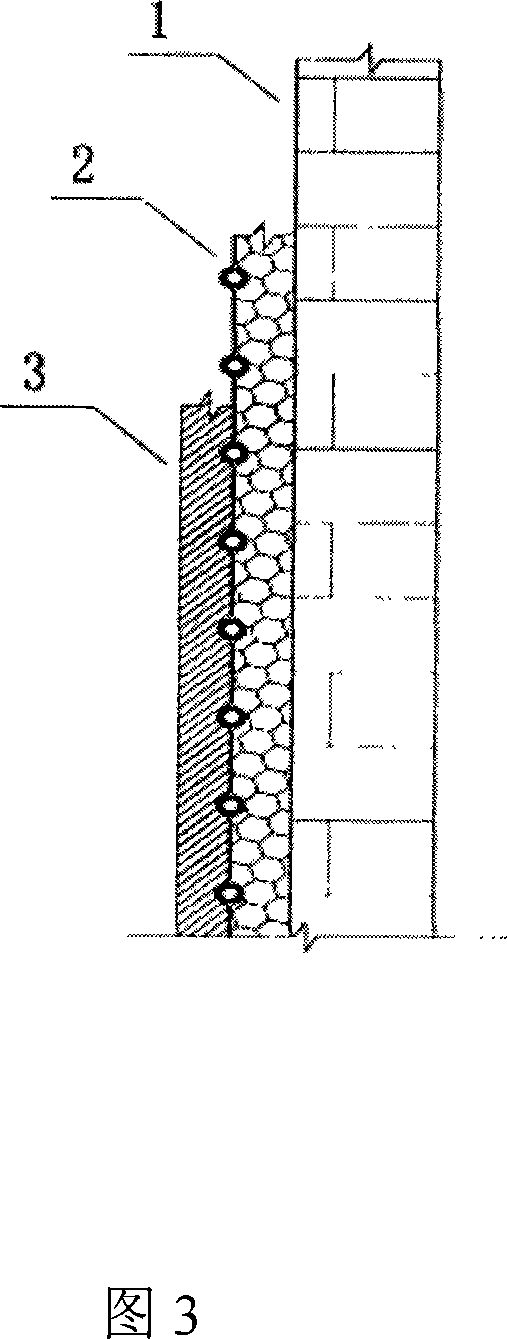

example 1

[0024] The thermal insulation layer is made of expanded benzene board or extruded benzene board, and the heat dissipation layer is made of metal foil with a thickness of 0.02-0.08mm; There are several grooves on the upper surface of the extruded styrene board, and the expanded styrene board or extruded board with grooves is laid flat; the metal foil is double-layered, and one side of each layer of metal foil is treated with self-adhesive or It is treated with an environmentally friendly adhesive; stick the self-adhesive surface of the first layer of metal foil on the groove surface of the expanded benzene board or extruded board, and then embed several capillaries of the water-collecting plastic pipe network on the surface attached to the surface. In the several grooves of the expanded benzene board or extruded benzene board of the metal foil, the self-adhesive surface of the second layer of metal foil is pasted on the upper surface of several capillaries, and the pasting surfa...

example 2

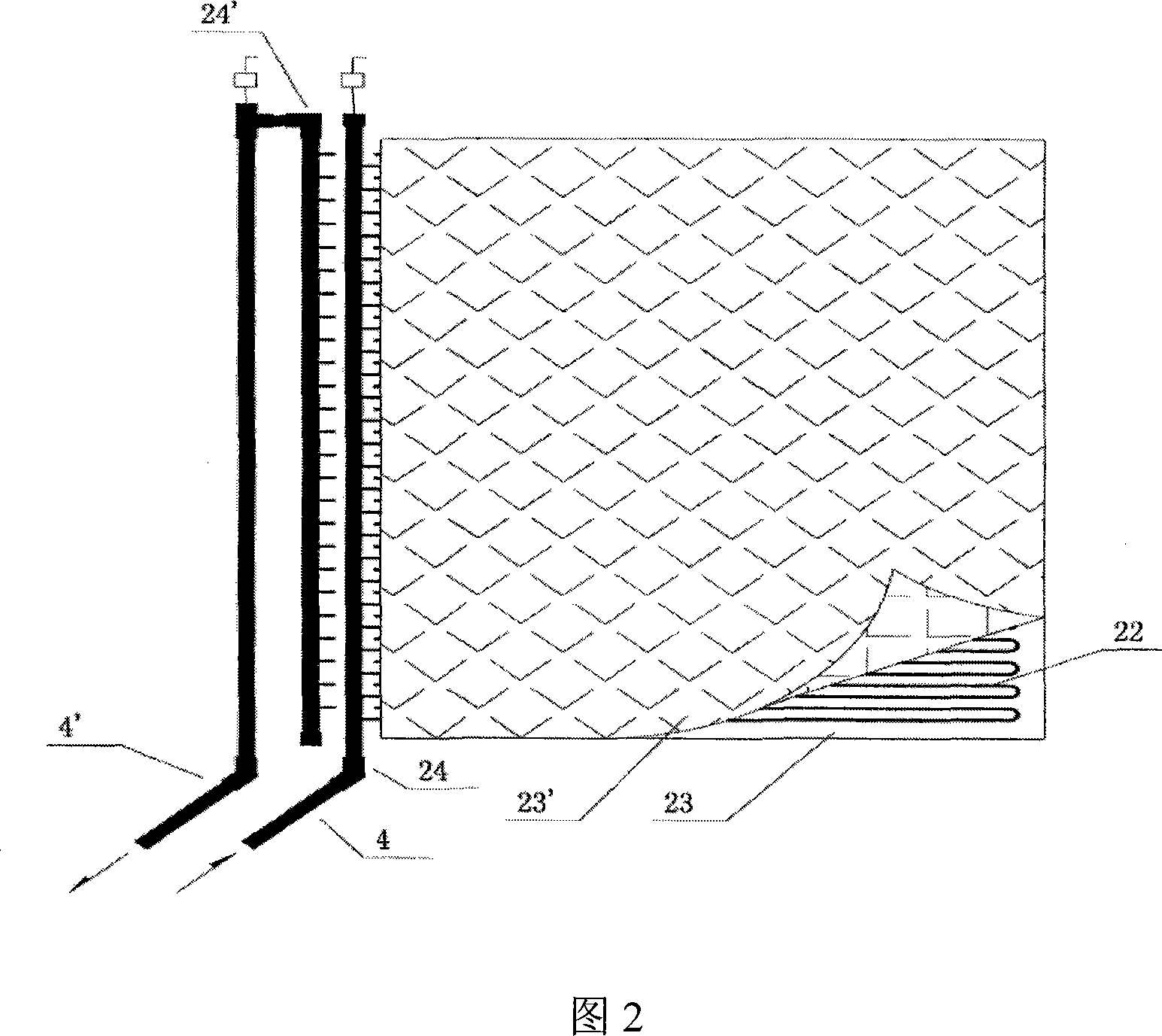

[0026] Use polyethylene film or rubber-plastic sponge for the insulation layer; use metal plates for the heat dissipation layer, with a thickness of 0.5-1.2mm; first spread the heat insulation film flat, and paste it on the self-adhesive surface of the first metal plate; Several capillaries of the water-collecting plastic pipe network are placed on the heat dissipation layer, and then the self-adhesive surface of the second layer of metal plate is pasted on the upper surface of several capillaries, and the paste surface connects several capillaries with the first layer. The surface of the metal plate is tightly bonded to eliminate the air partition; then seal and paste the metal plate and the periphery of the polyethylene film or rubber-plastic sponge, and leave the two main pipes of the water-collecting plastic network pipe outside the seal. The way of processing the self-adhesive surface of the metal plate, the connection and use of the input end and output end reserved by th...

example 3

[0028] The thermal insulation layer is made of thermal insulation board, such as any one of expanded benzene board or extruded benzene board, and the heat dissipation layer is made of metal plate with a thickness of 0.5-1.2mm; Pipe diameter and spacing: Several grooves are set on the surface of the expanded benzene board or extruded plastic board, and the expanded benzene board or extruded board with grooves is laid flat, and then the multiple capillaries of the water-collecting plastic pipe network are separated Embedded in several grooves of expanded benzene board or extruded benzene board, and then paste the self-adhesive surface of the metal plate on the upper surface of several capillaries, the metal plate connects several capillaries with expanded benzene board or extruded benzene The surface of the plate is tightly bonded to eliminate the air partition; then the metal plate and the periphery of the expanded benzene plate or extruded styrene plate are sealed and pasted, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com