Method of slurry dewatering and conversion of biosolids to a renewable fuel

A biosolids, conversion technology, applied in the direction of biofuels, solid fuels, waste fuels, etc., can solve the problems of controversial and expensive disposal of biosolids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

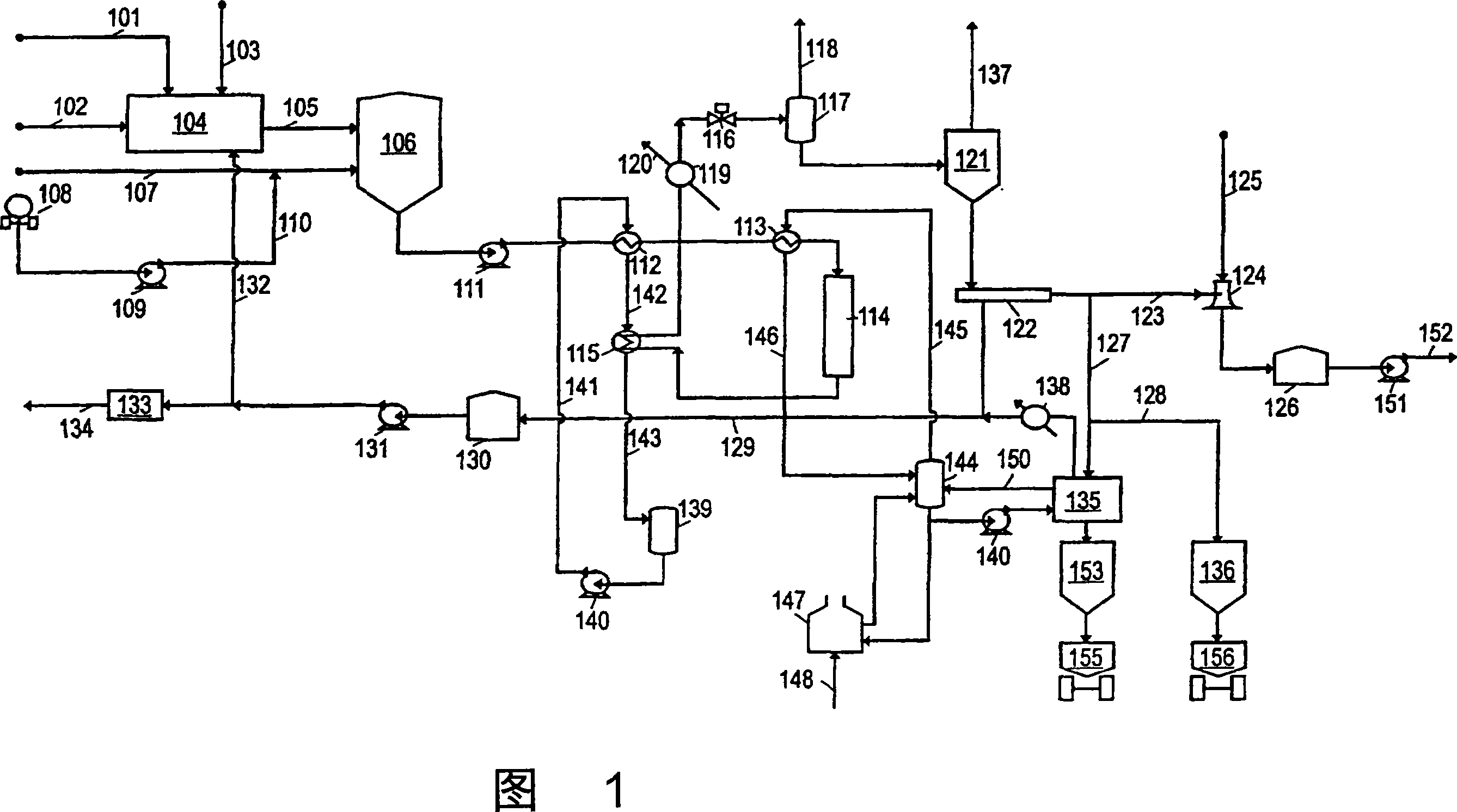

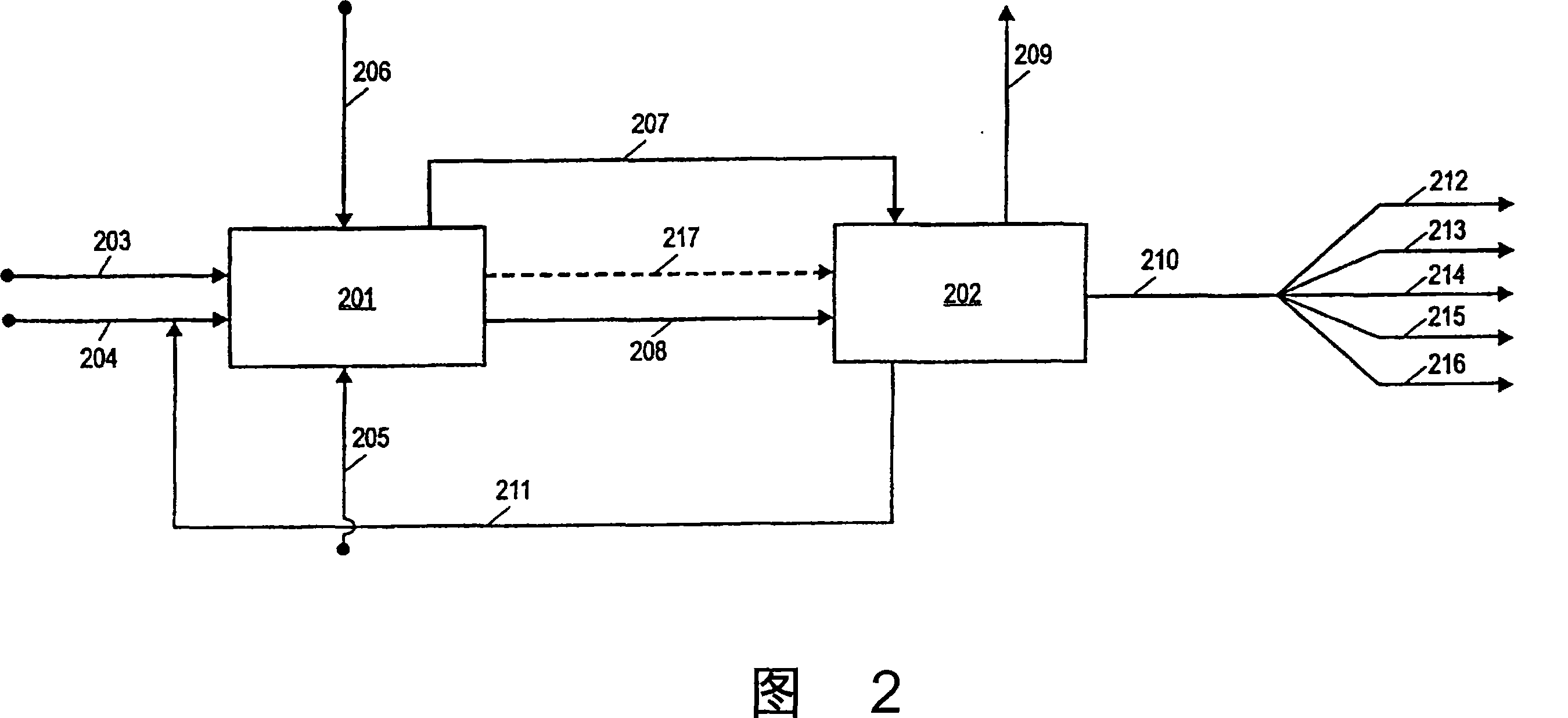

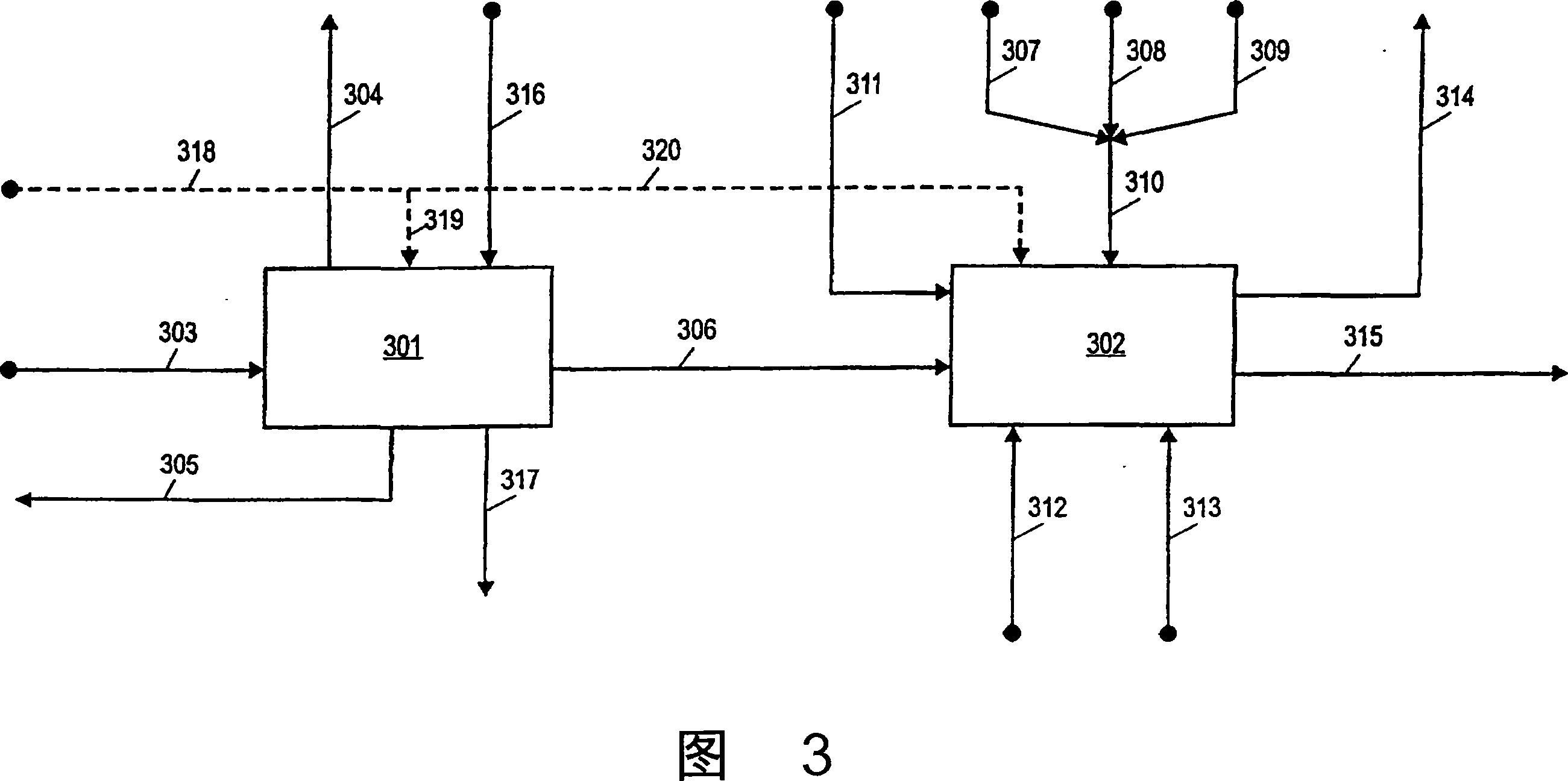

Method used

Image

Examples

Embodiment 1

[0115] Biosolids from two wastewater treatment plants (one located in Atlanta Georgia and the other located in Riverside California) were treated as previously described at a continuous pilot plant to produce and analyze the following products, the following results excluding moisture and ash:

[0116] Atlanta Biosolids Riverside Biosolids

[0117] Carbon 57.73 62.53

[0118] Hydrogen 7.48 9.26

[0119] Nitrogen 7.90 7.52

[0120] Sulfur 3.02 1.17

[0121] Oxygen 23.86 19.52

[0122] Total 100.00 100.00

[0123] Atlanta coke product Riverside coke product

[0124] Carbon 70.19 69.98

[0125] Hydrogen 8.85 7.68

[0126] Nitrogen 8.63 8.45

[0127] Sulfur 1.42 8.86

[0128] Oxygen 10.91 5.04

[0129] Total 100.00 100.00

[0130] As expected, the evolution of carbon dioxide leads to an increase in the carbon content and a correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com