SnAgCuBi series leadless soldering tin alloy

A lead-free solder and alloy technology, applied in the field of alloys, can solve the problems of cracking of solder joints, damage of electronic products, small solid-liquid coexistence temperature range, etc., to achieve uniform alloy composition, no impurities, high heating efficiency, and good wettability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

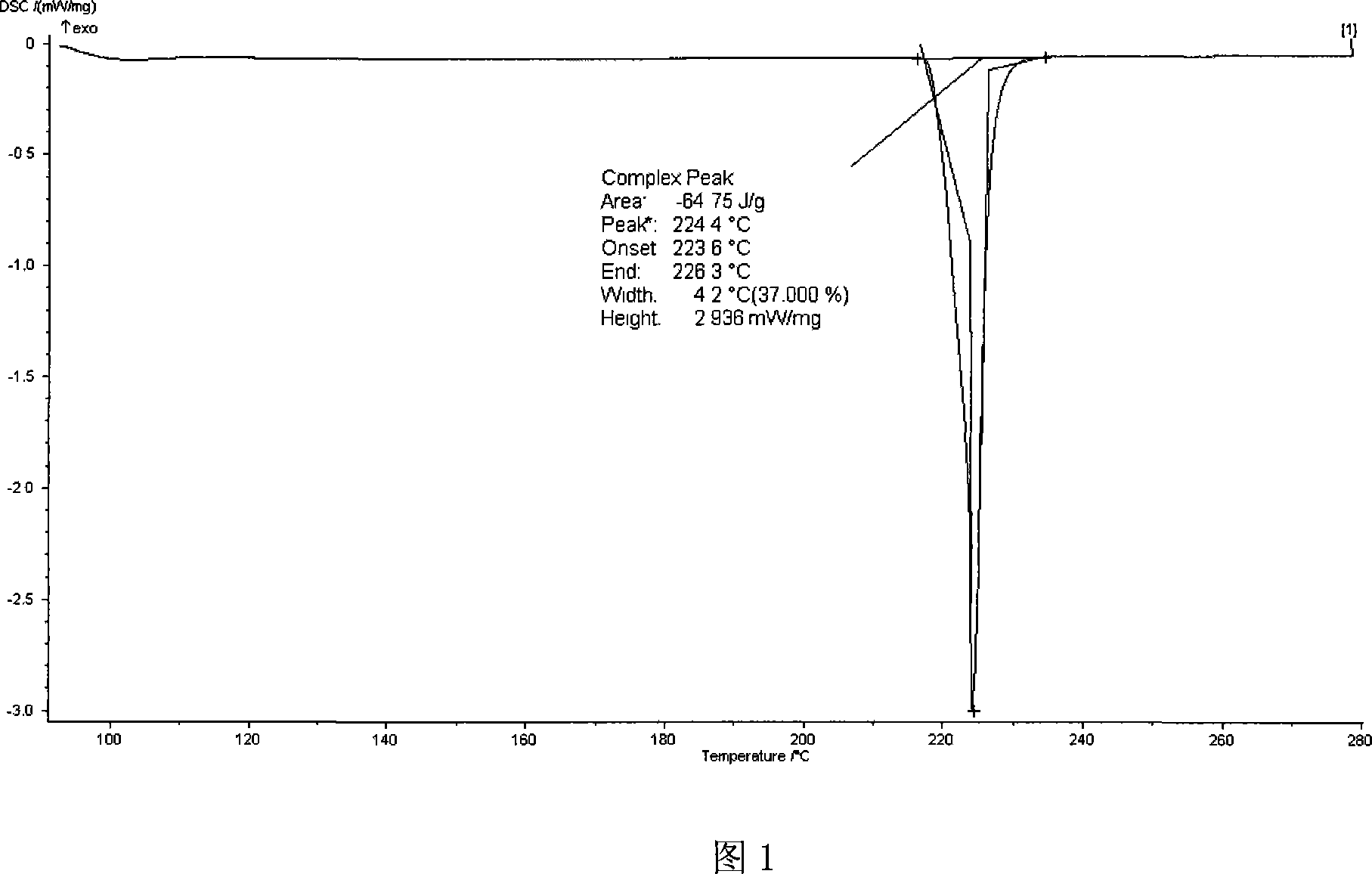

Embodiment 1

[0037] Example 1 The weight percent composition of the SnAgCuBi lead-free solder alloy is: Ag0.1%, Cu0.7%, Bi1.0%, Sb0.01%, Ni0.1%, La0.01%, P0.01% , and the rest are Sn.

[0038] The preparation method of the lead-free solder alloy is as follows: take each raw material according to the above weight percentage, and prepare the intermediate alloy first: configure a graphite crucible in a vacuum intermediate frequency induction melting furnace, put the raw materials into the graphite crucible according to the proportion, close the furnace body, and evacuate , intermediate frequency heating the metal to an appropriate temperature to keep it warm, and finally casting it into a corresponding alloy ingot.

[0039]a. Prepare a Sn-Ag alloy in a vacuum intermediate frequency induction melting furnace with a weight percentage of 70:30, raise the temperature to 1100° C. and keep it warm for 30 minutes, take it out of the furnace, cool and cast it into a tin-silver alloy ingot.

[0040] ...

Embodiment 2

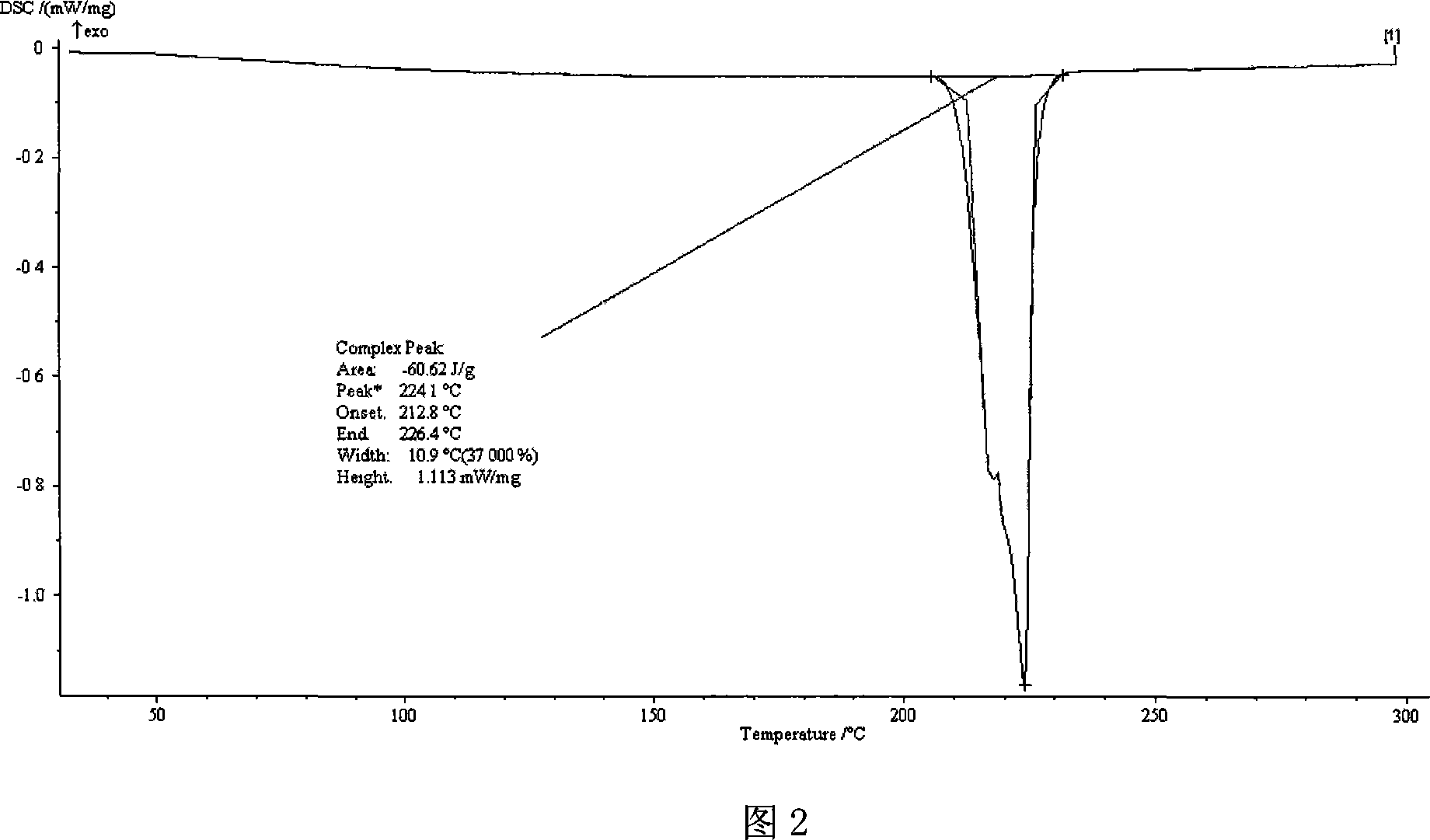

[0049] Example 2 The weight percent composition of the SnAgCuBi lead-free solder alloy is: Ag1.0%, Cu0.5%, Bi2.0%, Sb0.05%, Ni0.05%, La0.01%, P0.01% , the rest is Sn, and the preparation method is the same as in Example 1. The differential scanning calorimetry (DSC) curve during the heating process of the lead-free solder alloy measured by a thermal analysis instrument is shown in Figure 2, and its various performance test data are shown in the table below.

Embodiment 3

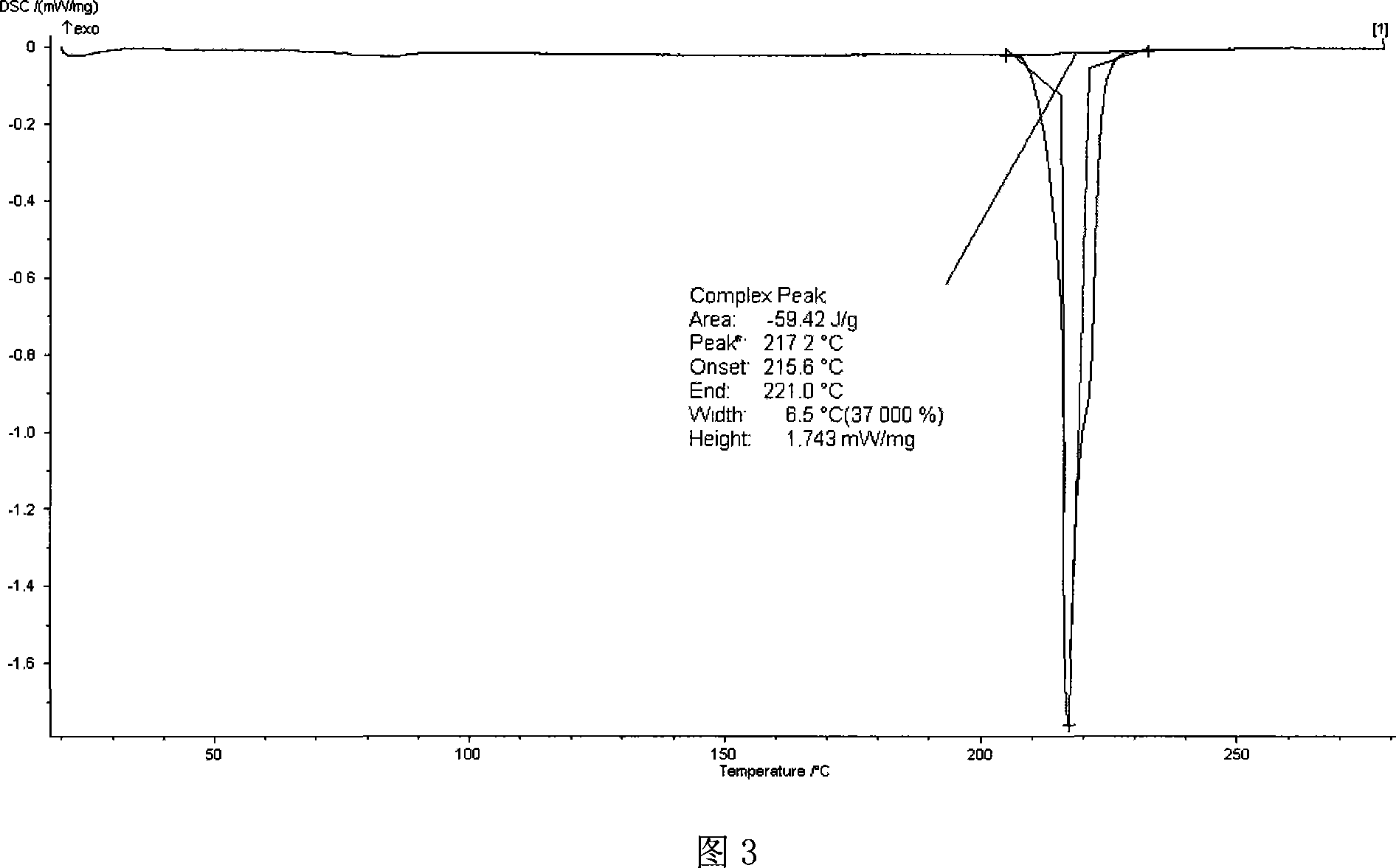

[0050] Example 3 The weight percent composition of the SnAgCuBi lead-free solder alloy is: Ag2.0%, Cu0.1%, Bi3.0%, Sb0.1%, Ni0.1%, La0.01%, P0.01% , and the rest are Sn. , the preparation method is the same as in Example 1. The differential scanning calorimetry (DSC) curve during the heating process of the lead-free solder alloy measured by a thermal analysis instrument is shown in Figure 3, and its various performance test data are shown in the table below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com