SnAgCuNi series leadless soldering tin alloy

A lead-free solder and alloy technology, applied in the field of alloys, can solve the problems of increasing the production difficulty and cost of PCB boards and electronic components, and achieve the effects of good wettability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

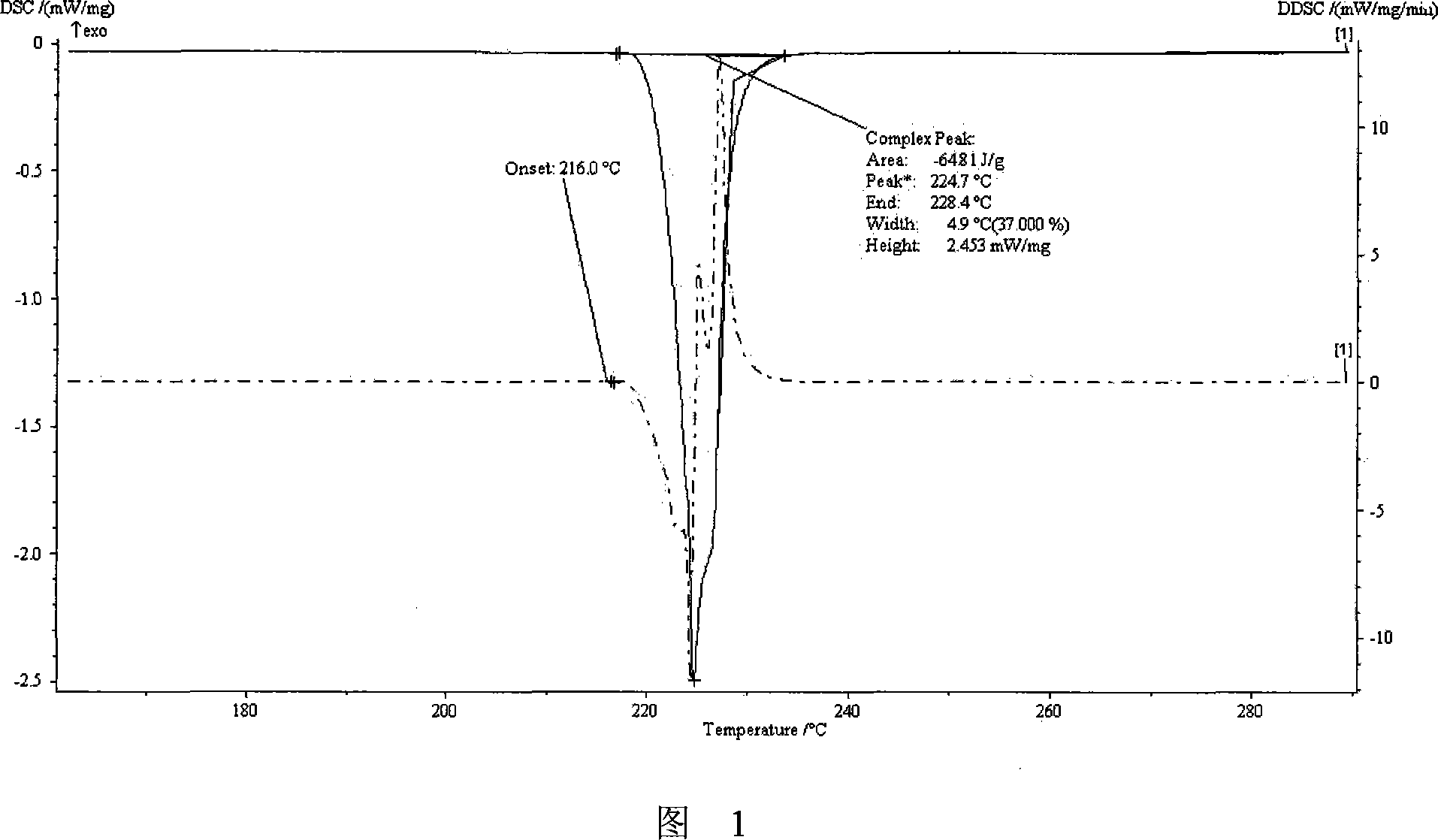

Embodiment 1

[0030] Example 1 SnAgCuNi lead-free solder alloy, its weight percent composition: 1.5% of Ag, 0.5% of Cu, 0.5% of Ni, 0.01% of Bi, 0.01% of P, and the balance of Sn and unavoidable of impurities. Its preparation method is as follows: first take the raw materials according to the following weight: 1.5 parts by weight of Ag, 0.5 parts by weight of Cu, 0.5 parts by weight of Ni, 0.01 parts by weight of Bi, 0.01 parts by weight of P, and 97.28 parts by weight of Sn.

[0031] The Sn-Ag alloy was prepared in a vacuum intermediate frequency induction melting furnace with a weight percentage ratio of 70:30, the temperature was raised to 1100°C and kept for 30 minutes, and the tin-silver alloy ingot was cast out of the furnace for cooling.

[0032] The Sn-Cu alloy was prepared in a vacuum intermediate frequency induction melting furnace with a weight percentage ratio of 70:30, the temperature was raised to 1200°C and kept for 30 minutes, and the tin-copper alloy ingot was cast out of t...

Embodiment 2

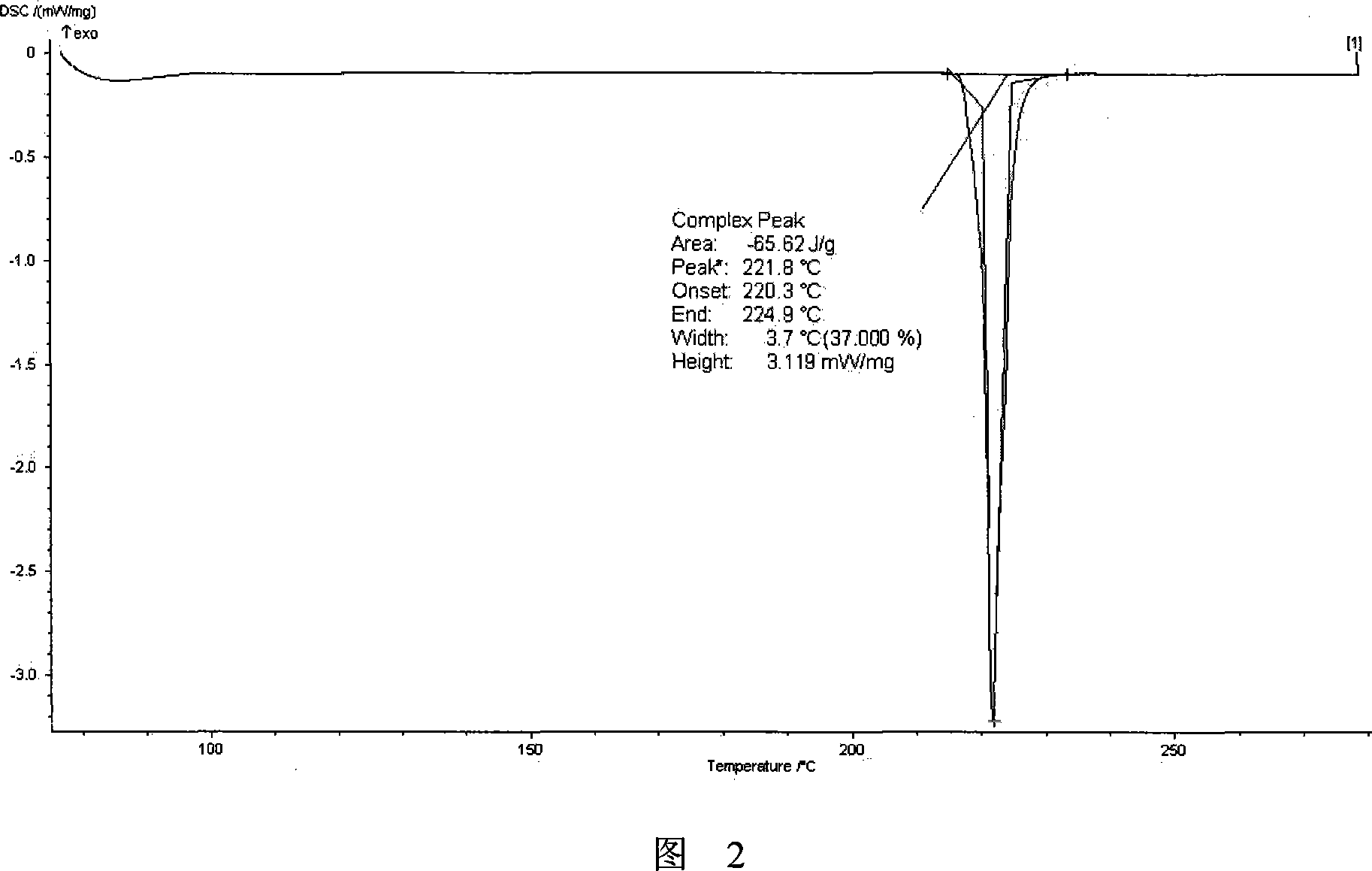

[0038] Example 2 The weight percent composition of the lead-free solder alloy is: 2.0% Ag, 0.5% Cu, 0.01% Ni, 0.01% Bi, 0.01% P, and the balance of Sn and unavoidable impurities, Its preparation method is with embodiment 1.

[0039] Adopt thermal analysis instrument to carry out thermal analysis to the lead-free solder alloy of preparation, obtain differential scanning calorimetry (DSC) curve and see accompanying drawing 2, find out from the figure, in the melting temperature of this lead-free solder alloy, solidus and The liquidus temperatures are 220.3°C and 221.8°C, respectively. The solder alloy is used for PCB component welding experiments, and has good wetting properties and oxidation resistance, and its mechanical properties are superior to the existing national standards for lead-containing solder alloys.

Embodiment 3

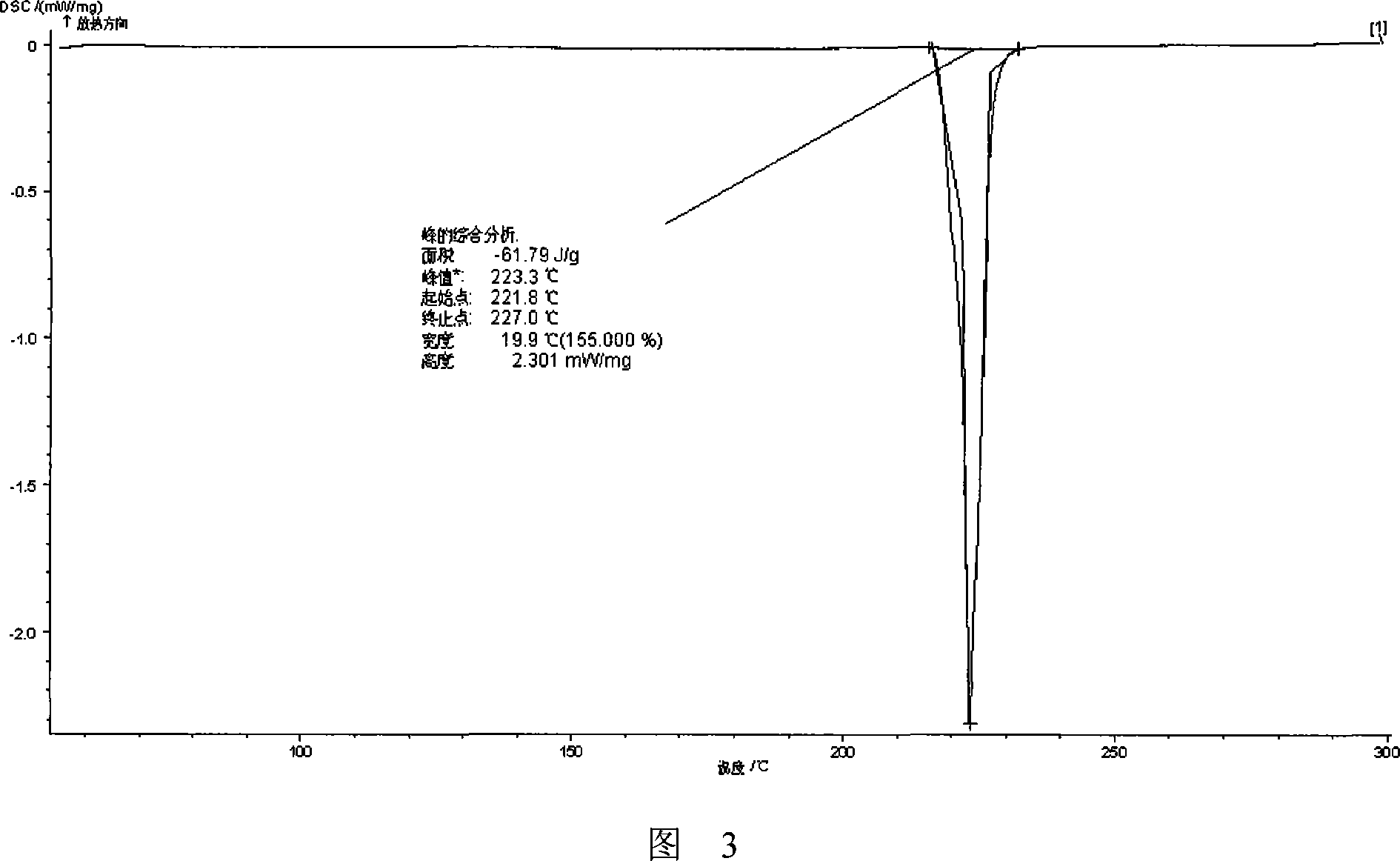

[0040] Embodiment 3 The weight percent composition of the lead-free solder alloy is: 2.0% Ag, 0.5% Cu, 0.2% Ni, 0.01% P, and the balance of Sn and unavoidable impurities. Its preparation method is the same as in Example 1, and no Sn-Bi intermediate alloy is added to the solder alloy.

[0041]Adopt thermal analysis instrument to carry out thermal analysis to the lead-free solder alloy of preparation, obtain differential scanning calorimetry (DSC) curve and see accompanying drawing 3, find out from the figure, in the melting temperature of this lead-free solder alloy, solidus and The liquidus temperatures are 221.8°C and 223.3°C, respectively. The solder alloy is used for circuit component welding experiments, and has good wetting performance and oxidation resistance, and its mechanical properties are superior to the existing national standards for lead-containing solder alloys.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com