Electric polyaniline derivative surface modified water decentralized carbon nano-tube and preparation method

A technology of conductive polyaniline and aniline derivatives, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as low conductivity, achieve good water dispersibility, less environmental pollution, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

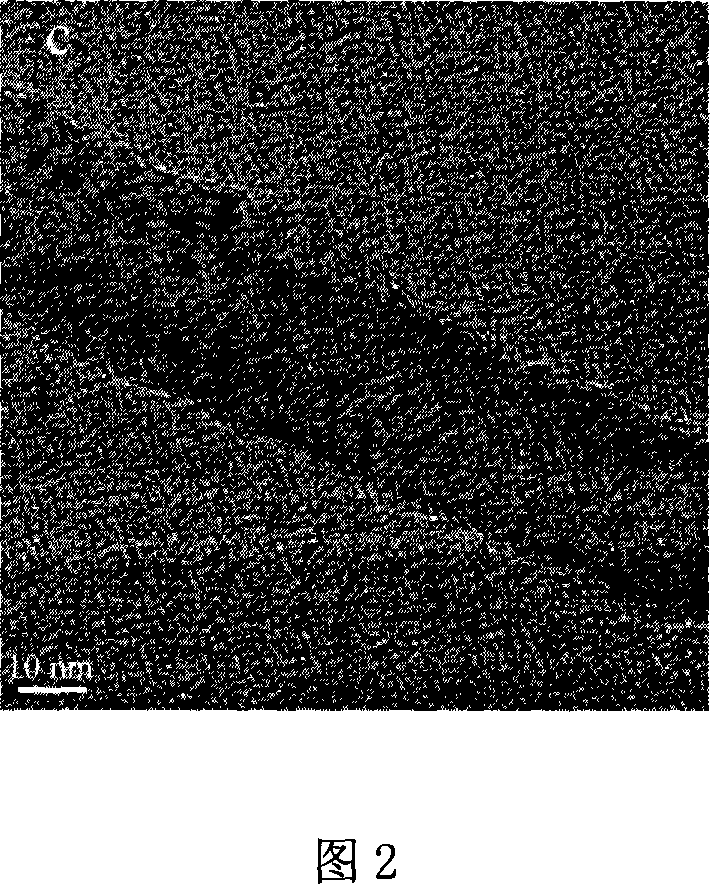

[0022] Dissolve 1 g of anthranilic acid monomer in 1 mol / L hydrochloric acid aqueous solution, then add 1 g of multi-walled carbon nanotubes (with a diameter of 10-20 nm) into the above aqueous solution, and ultrasonically treat for 2 hours to make carbon The nanotubes are evenly dispersed; take 1.3g of ammonium persulfate, make 10mL solution with deionized water, control the molar ratio of anthranilic acid to ammonium persulfate to be 1:1, and then slowly add the ammonium persulfate aqueous solution to the above In the reaction system, react at 25° C. for 24 hours, filter, wash and dry to obtain water-dispersible carbon nanotubes with conductive polyanthranilic acid surface-modified. Through elemental analysis, it was determined that the content of polyanthranilic acid on the surface of the modified carbon nanotubes was 36.8wt%.

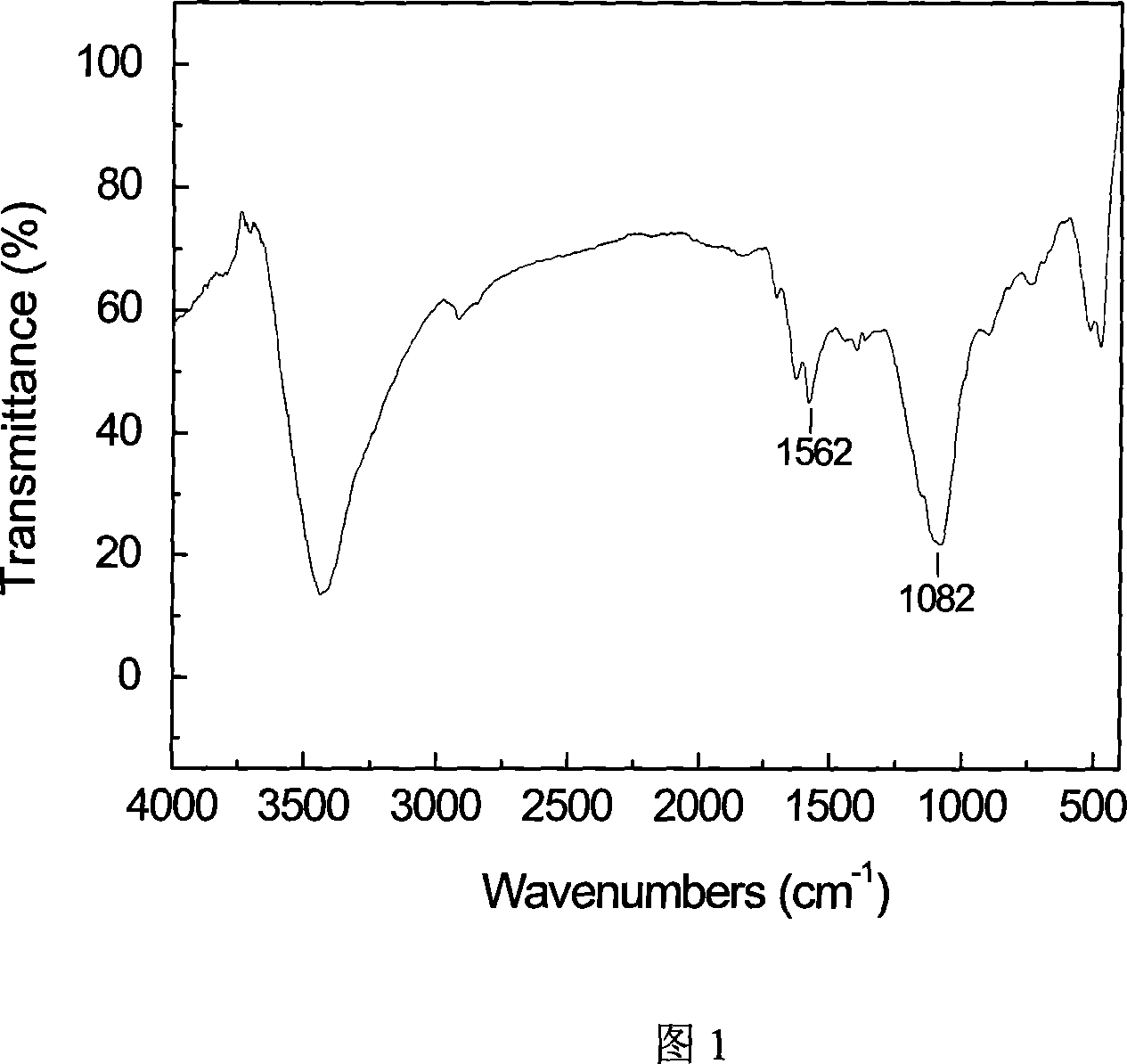

[0023] Figure 1 shows the infrared analysis results of polyanthranilic acid surface-modified carbon nanotubes, 1562cm -1 and 1082cm -1 The absorp...

Embodiment 2

[0027] 0.1g of anthranilic acid monomer is dissolved in 3mol / L hydrochloric acid aqueous solution, then 1g of multi-walled carbon nanotubes (its diameter is 10-20nm) is added in the above-mentioned aqueous solution, through ultrasonic treatment 1 hour, make Carbon nanotubes are uniformly dispersed; get 0.26g ammonium persulfate, make 5mL solution with deionized water, control the molar ratio of anthranilic acid and ammonium persulfate to be 1:2, then slowly add the ammonium persulfate aqueous solution to the In the above reaction system, react at 25° C. for 48 hours, filter, wash and dry to obtain water-dispersible carbon nanotubes surface-modified with conductive polyanthranilic acid. Through elemental analysis, it was determined that the content of polyanthranilic acid on the surface of the modified carbon nanotube was 4.2wt%.

[0028] Its conductivity was tested with a four-probe instrument to be 10.2 S / cm.

[0029] A sedimentation test was used to evaluate the water dispe...

Embodiment 3

[0031] Dissolve 5 g of anthranilic acid monomer in 2 mol / L hydrochloric acid aqueous solution, then add 1 g of multi-walled carbon nanotubes (with a diameter of 10-20 nm) into the above aqueous solution, and ultrasonically treat for 1 hour to make carbon The nanotubes are evenly dispersed; take 6.5g of ammonium persulfate, make 50mL solution with deionized water, control the molar ratio of anthranilic acid to ammonium persulfate to be 1:1, then slowly add the ammonium persulfate aqueous solution to the above In the reaction system, react at 25° C. for 24 hours, filter, wash and dry to obtain water-dispersible carbon nanotubes with conductive polyanthranilic acid surface-modified. Through elemental analysis, it was determined that the content of polyanthranilic acid on the surface of the modified carbon nanotube was 56.2wt%.

[0032] Its conductivity is 16.2S / cm measured with a four-probe instrument.

[0033] A sedimentation test was used to evaluate the water dispersion stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com