Water-base neutrality steel chromium-free strong passivator

A passivating agent, neutral technology, applied in the direction of metal material coating process, etc., can solve the problem of undiscovered film-forming and self-repairing ability, unable to completely maintain the original appearance of the workpiece, and the workpiece is not suitable for use, reaching the price Low cost, low cost, good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

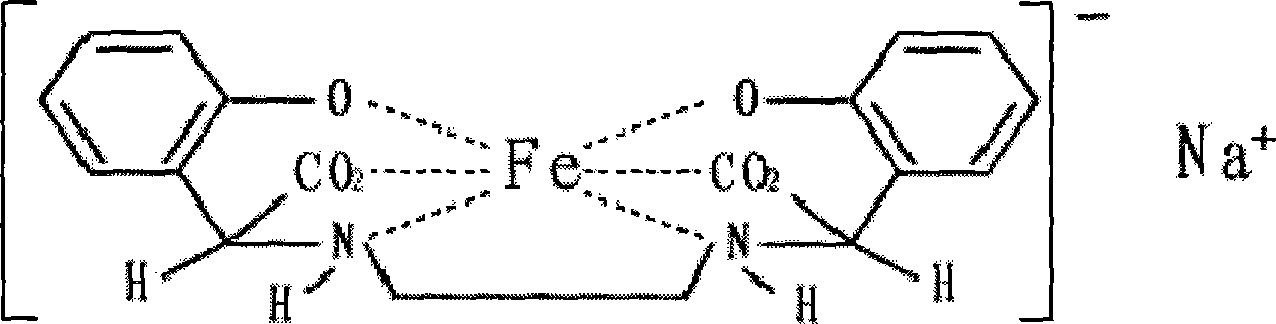

[0052] Weigh 40g of triphenylcyclic imidazoline quaternary ammonium salt and 200g of sodium molybdate respectively, put them into a 2400g water container and mix evenly until they are completely dissolved to make semi-finished products for later use. Weigh 6330g of water, put it into a container and heat it to 40°C, then add 500g of sodium ferric acetate diethylenediamine di-o-hydroxyphenyl macroacetate, 30g of light rare earth lanthanum (La), 200g of phytic acid ester, and 300g of hydroxylamine sulfate (HAS) It is sufficient to stir without particles, and 10kg of water-based neutral steel chromium-free strong passivator can be obtained.

example 2

[0054] Take by weighing 50g of triphenylcyclic imidazoline quaternary ammonium salt and 250g of ammonium molybdate, put them into a 3000g water container and mix evenly until they are completely dissolved to make semi-finished products for later use. Weigh 4990g of water, put it into a container and heat it to 40°C, add 1000g of ethylenediamine di-o-hydroxyphenyl macroacetate sodium ferric acetate, 60g of light rare earth cerium (Ce), 250g of phytic acid ester, and 400g of hydroxylamine sulfate (HAS) It is sufficient to stir without particles, and 10kg of water-based neutral steel chromium-free strong passivator can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com