Method of manufacturing fire-resistant high-performance organic pulp-shape fibre

A manufacturing method and organic fiber technology, which is applied in the field of manufacturing high-temperature-resistant high-performance organic pulp-like fibers, can solve problems such as industrialization difficulties and low efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

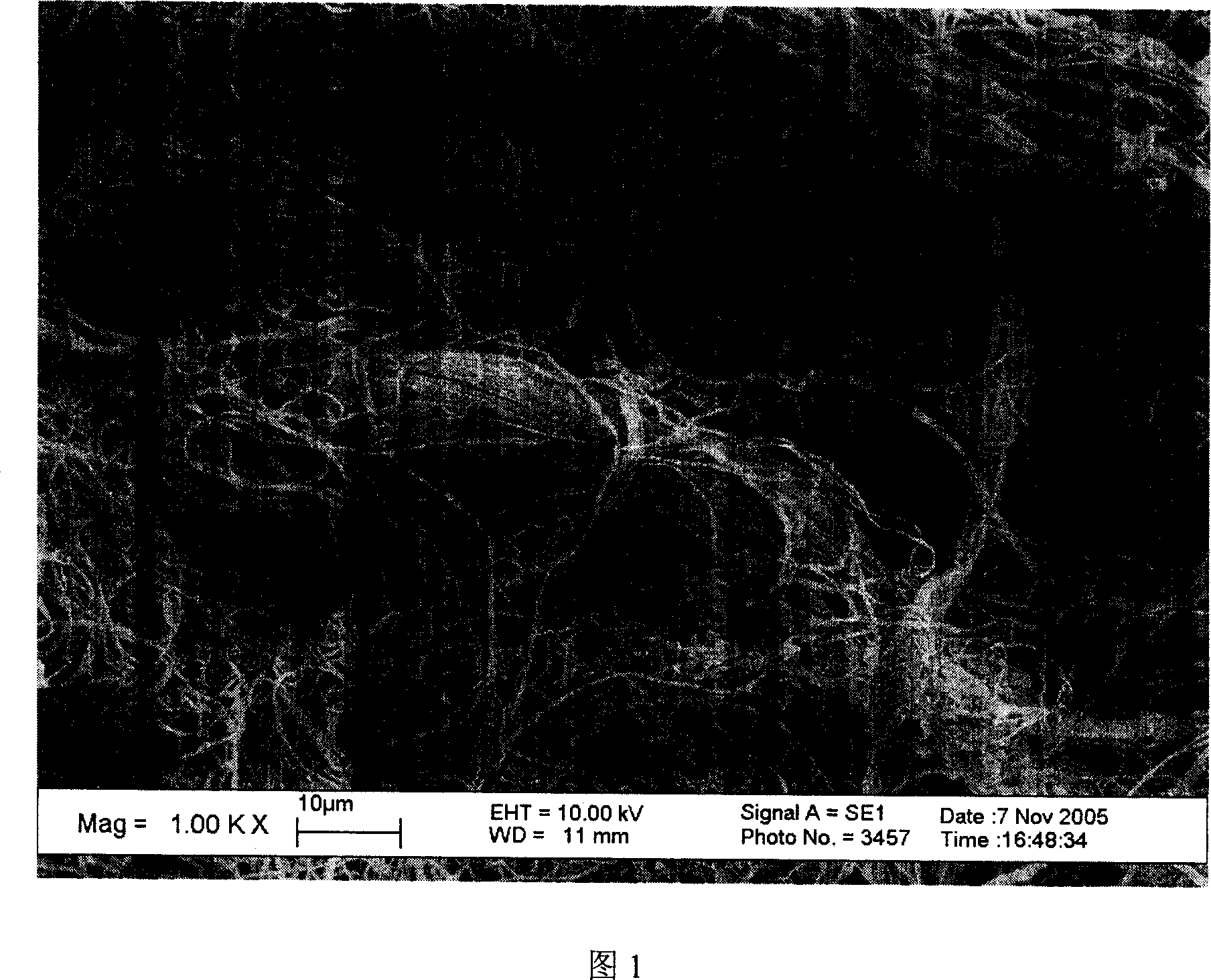

[0023] Punch a batch of aramid waste silk for optical cables into chopped fibers with a length of 4-6 mm on a punching machine with a nominal force of 63 tons, weigh 50 kg and disperse them in 5 tons of acrylamide copolymer containing 180 g of quaternary ammonium salt and 60 g of polyacrylic acid In the water of the polymer dispersant compounded by salt polymer, the suspension formed is pumped into a three-stage pipeline high-shear dispersing emulsifier at a flow rate of 5t / h for grinding, and the obtained slurry is centrifugally dehydrated and dried to obtain Aramid pulp-like fibers with a length distribution of 2.1±0.4mm and a specific surface area of 7±2m 2 / g.

example 2

[0025] Punch a batch of aramid waste silk for optical cables into short cut fibers with a length of 4-6 mm on a punching machine with a nominal force of 63 tons, weigh 75 kg and disperse them in 5 tons of acrylamide copolymer containing 240 g of quaternary ammonium salt and 80 g of polyacrylic acid In the water of the polymer dispersant compounded by salt polymer, the formed suspension is pumped into a three-stage pipeline high-shear dispersing emulsifier at a flow rate of 2.5t / h for grinding, and the obtained slurry is centrifugally dehydrated and dried. Obtain aramid pulp-like fibers with a length distribution of 2.0±0.4mm and a specific surface area of 11±2m 2 / g.

example 3

[0027] 150g of the PBO spinning test product was punched into short-cut fibers with a length of 3-5mm on a punching machine with a nominal force of 63 tons, dispersed in 20kg of water, and ground for 8min by a double-disk refiner, and the obtained slurry was centrifuged and dehydrated. After drying, PBO pulp-like fibers are obtained, the length distribution is 2.0±0.4mm, and the specific surface area is 9±2m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com