Electronic bubble surface low temperature depositional film manufacture method

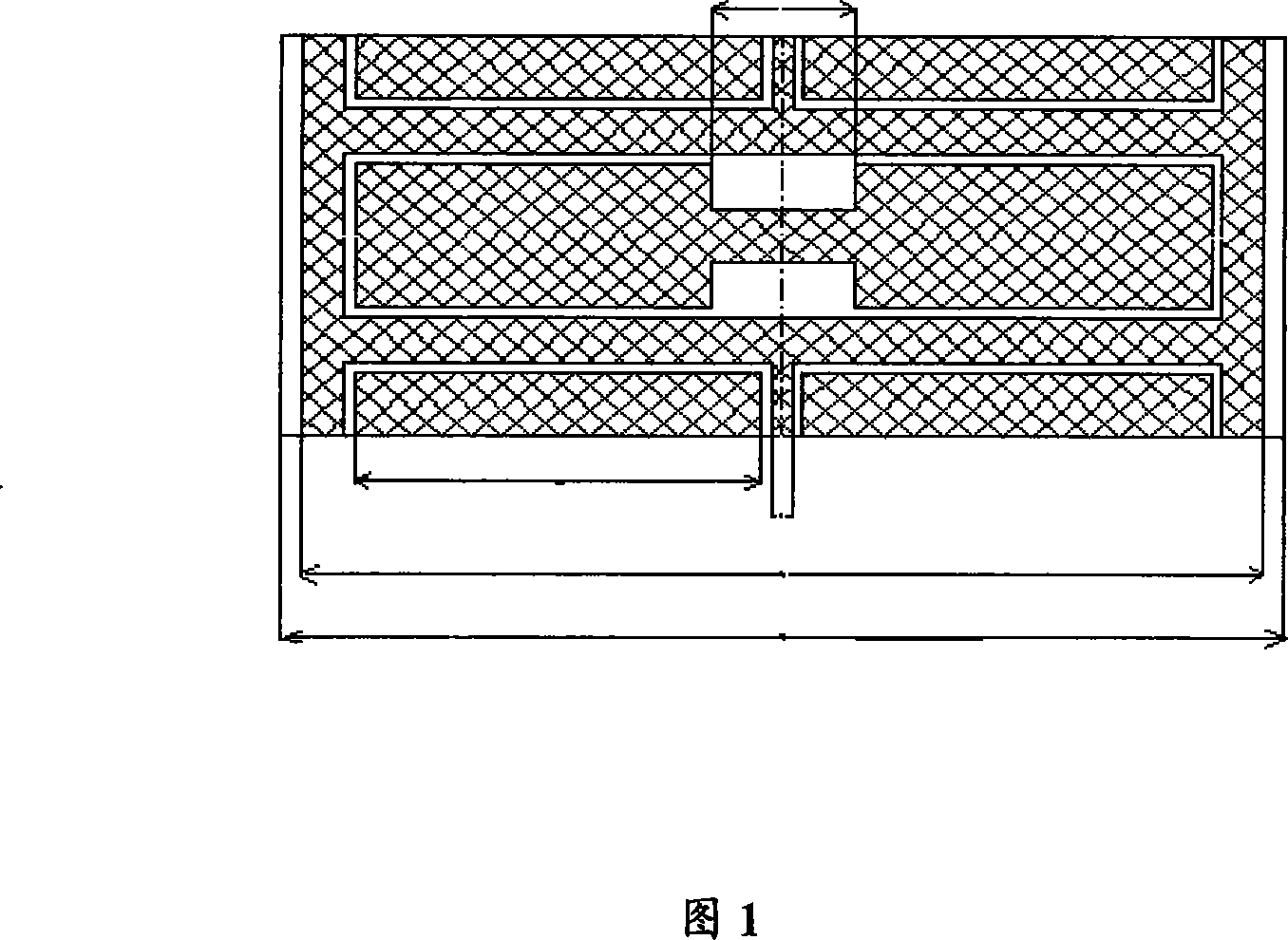

A technology of surface deposition and blisters, applied in stacked capacitors, thin film/thick film capacitors, etc., can solve the problems of uneven conductive layer thickness, inaccurate measurement results, damage to electronic blisters, etc., to achieve smooth peeling off and high sensing sensitivity , the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] First clean the glass surface:

[0024] Soak in a mixture of analytical ethanol and ether at a ratio of 3:1 to remove oil stains; then use ultrasonic cleaning; finally wipe dry with analytical ethanol and dry the glass surface with a dry hot air blower and a flat nozzle.

[0025] Apply photosensitive glue on the blank part of the surface of the electronic blister and cure it with ultraviolet light.

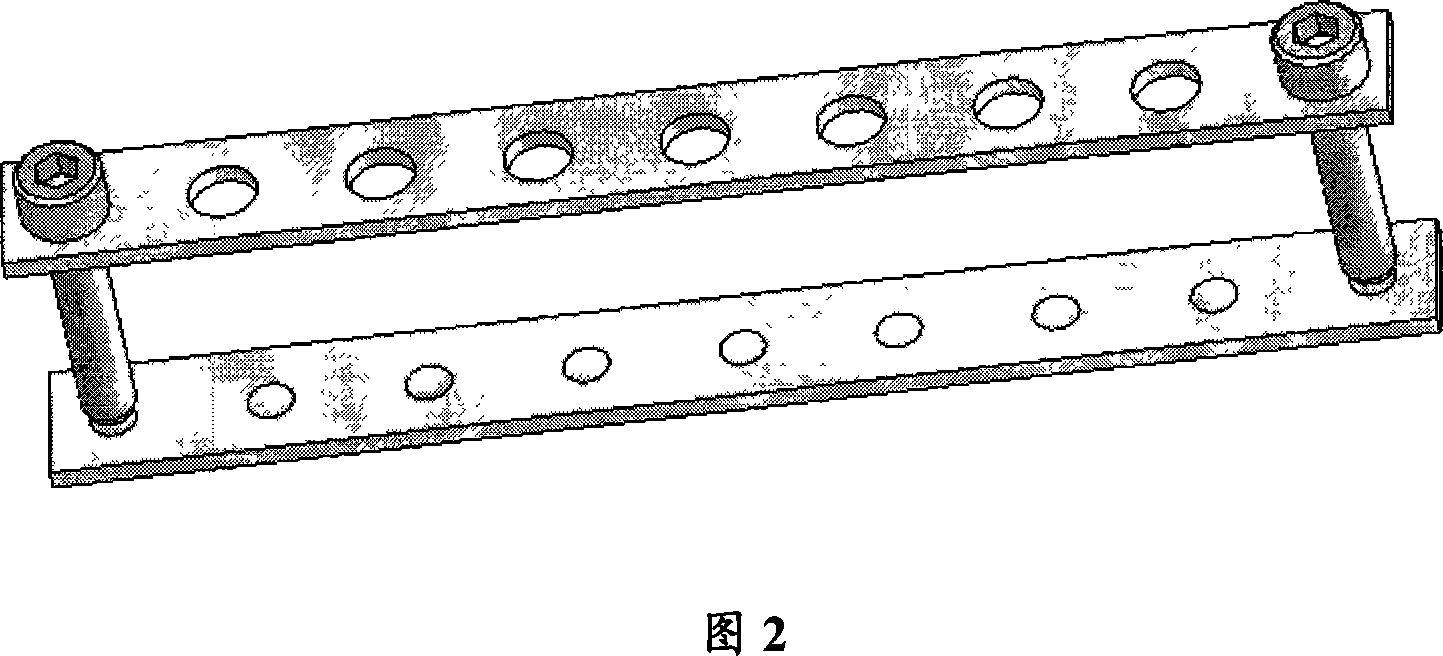

[0026] Install the fixture:

[0027] As shown in Figure 2, put the electronic water bubbles into the holes of the fixture 4 one by one, clamp the fixture 4 and put it into the vacuum chamber 8, and connect it to the rotating motor 1;

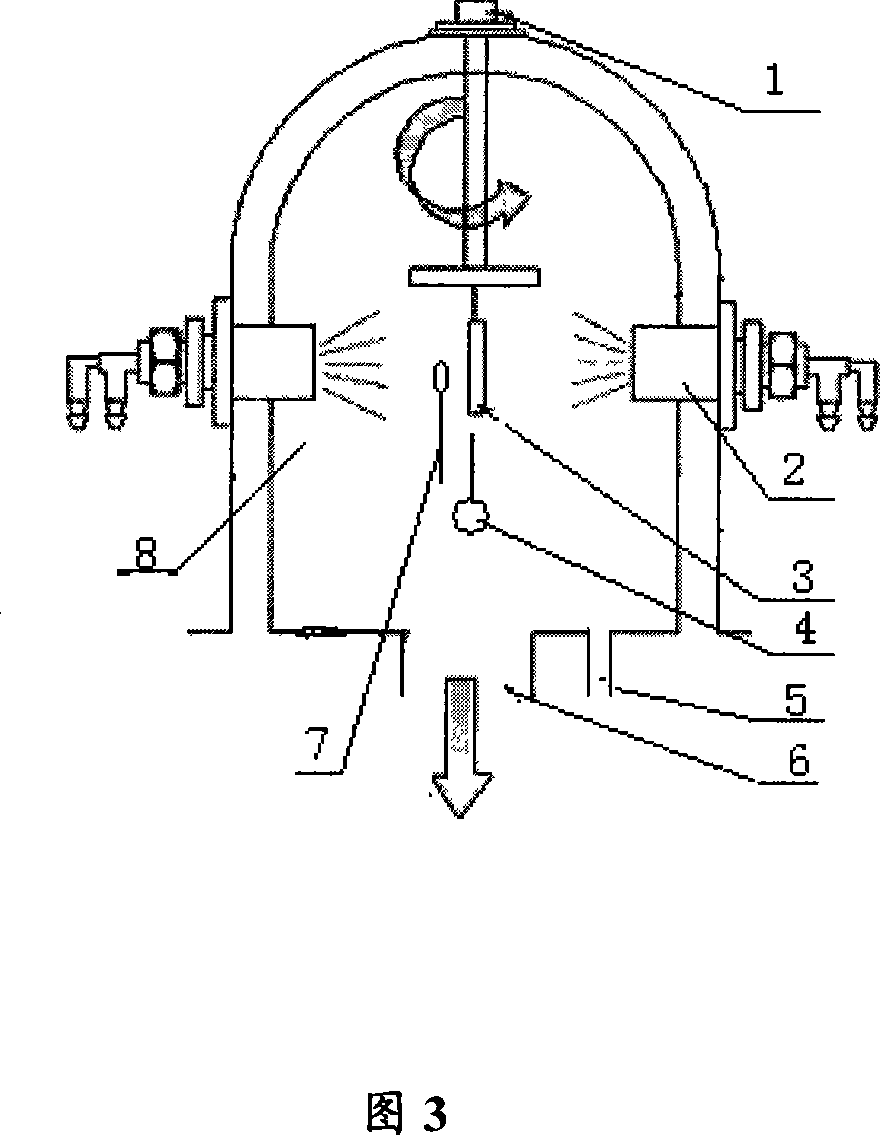

[0028] DC magnetron sputtering:

[0029] As shown in Figure 3, put the clamp 3 shown in Figure 2 into the vacuum chamber 8 after being clamped, and vacuumize the vacuum chamber 8 through the vacuum port 6 to obtain a background vacuum degree of 10 -3 Pa, then fill argon into the vacuum chamber 8 through the argon gas inlet 5; control the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com