Device for carbonization and cracking at high temperature and the pyrolysis method

A high-temperature dry distillation and thermal cracking technology, which is applied in the treatment of tobacco, tobacco, applications, etc., can solve the problems of large funds, data reliability discounts, and high equipment costs, and achieve the effects of enhanced representativeness, reduced equipment costs, and reasonable equipment configurations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

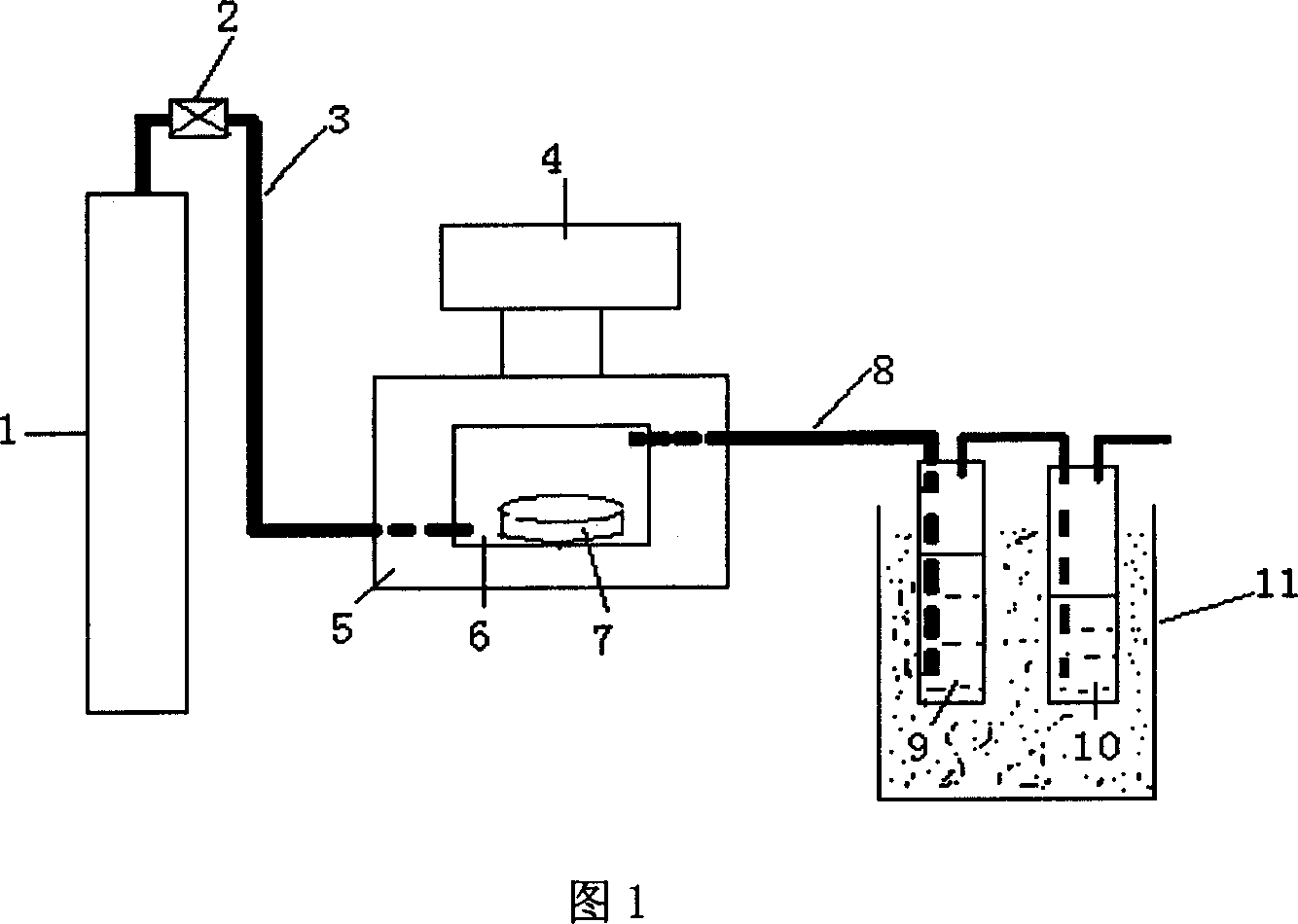

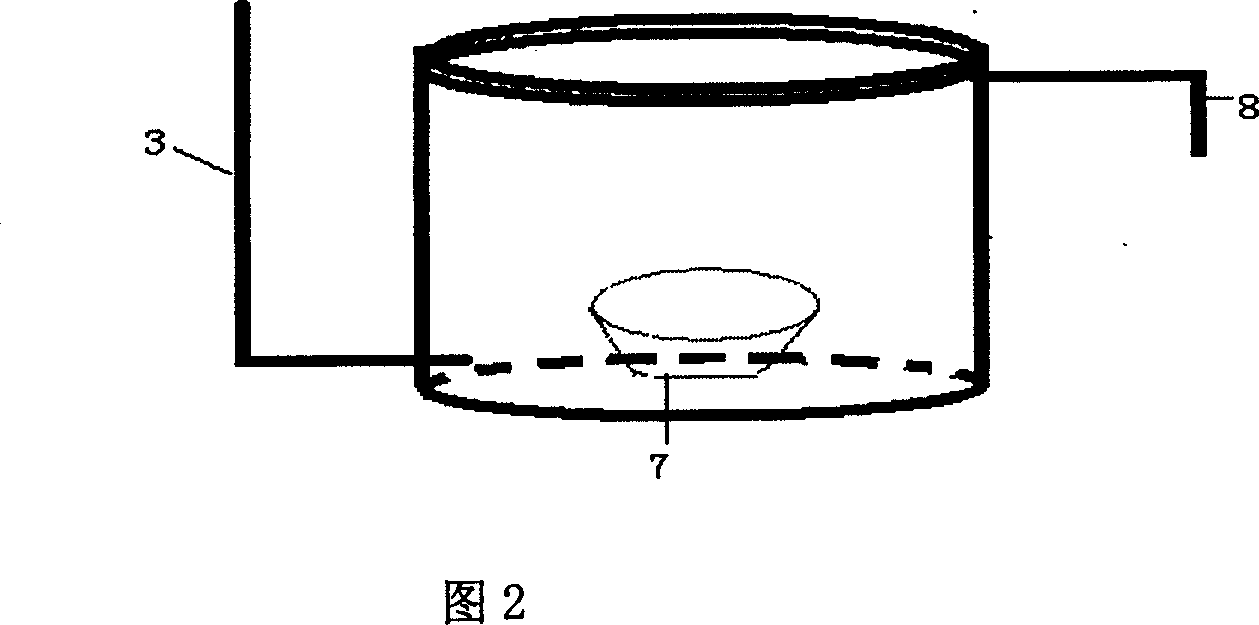

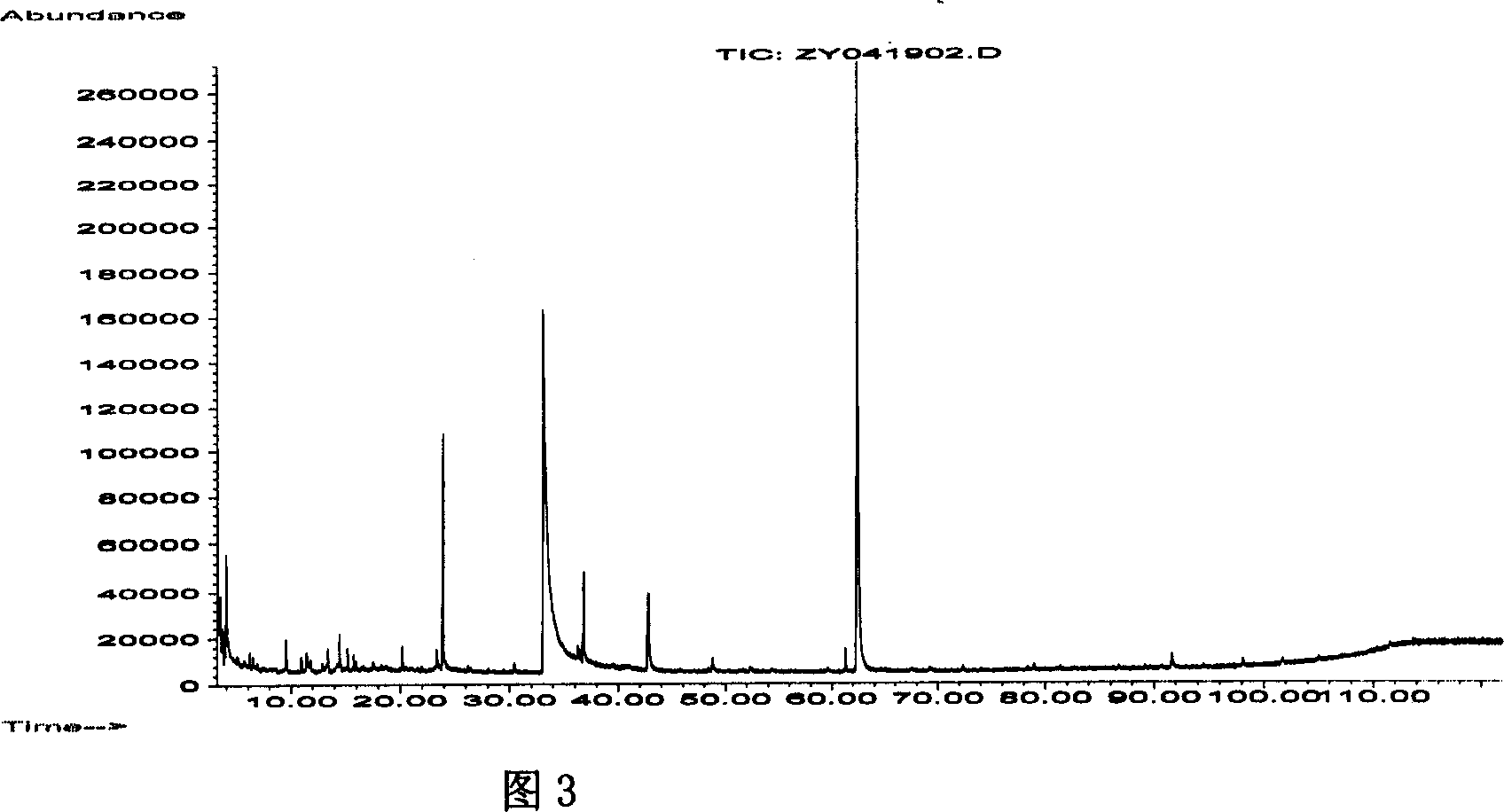

[0020] Refer to Figure 1 for specific connections. The tobacco leaves are ground into powder in advance and passed through a 80-100 mesh sieve. The temperature controller 4 is set at a certain temperature earlier, and the horse boiler 5 is heated to the specified temperature. Weigh 10 grams of the above smoke powder, put it into a cracking tank, cover it tightly and connect it to an inert gas cylinder, and check its airtightness with water in advance. After the collection solvents (such as dichloromethane, absolute ethanol or acetone, etc.) are installed in the first-stage collection bottle and the second-stage collection bottle respectively, they are connected with the cracking tank. Immediately put the cracking tank into the center of the horse boiling furnace and close the door immediately, and control the air flow precision regulating valve so that the cracking gas bubbles at a moderate speed in the first-stage collecting bottle. After 2-3 hours of lysis, wash the cracki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com