Filtering liquor treating process for urban consumer waste landfill

A technology for municipal solid waste and landfill leachate, which is applied in water/sewage multi-stage treatment, degassed water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of poor removal of heavy metal pollutants and adsorption materials. The problems of high price and high cost of sewage treatment can achieve the effect of easier control of process parameters, obvious removal effect and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

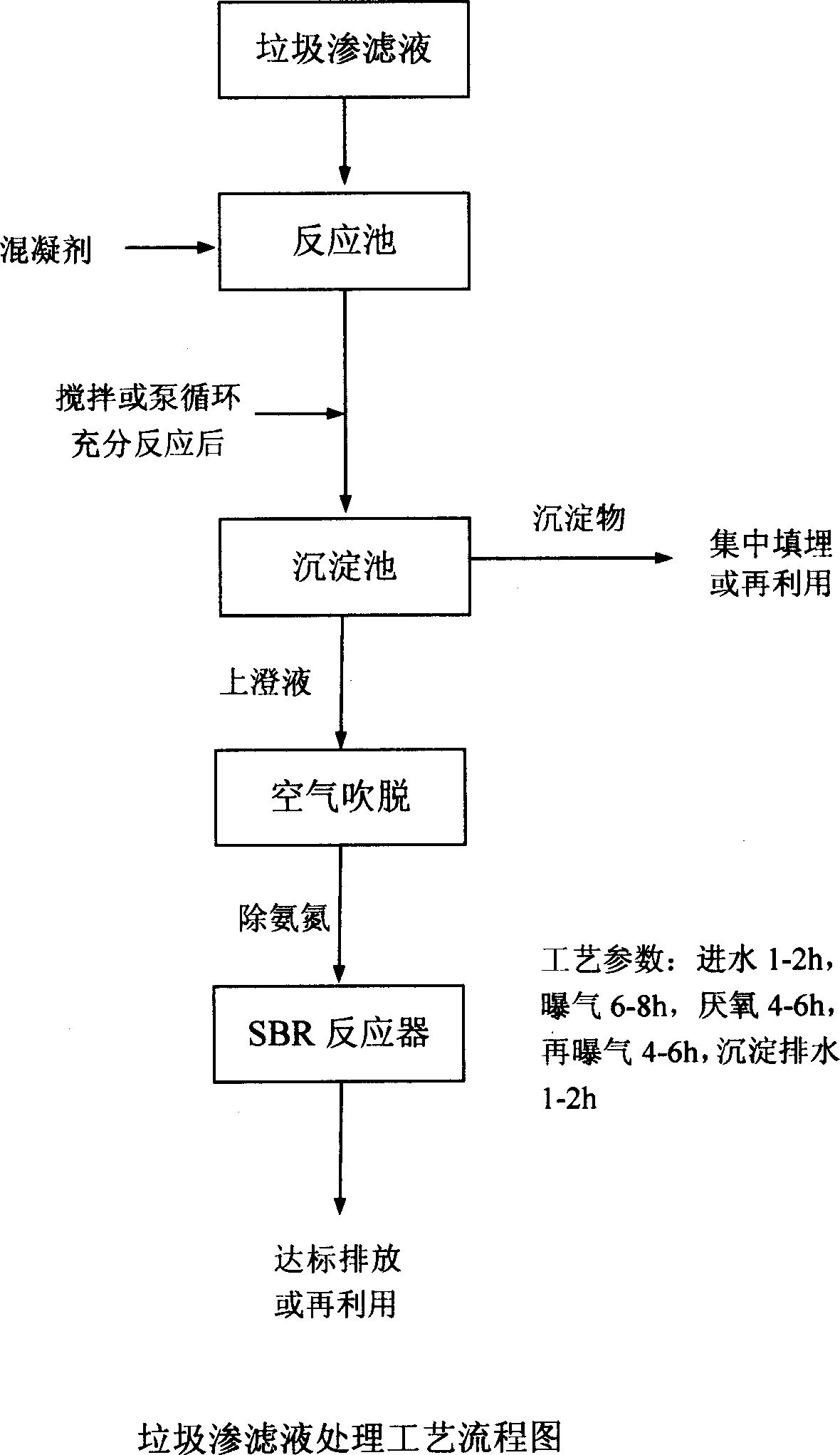

[0043]Inject 60L of aged landfill leachate, which has been continuously produced and stored since Dalian Municipal Solid Waste Landfill was in operation in 2002, into the reaction tank, and add coagulant according to the dosage of 105g / L (leachate), and stir After 90 minutes, let stand for 30 minutes, and analyze the water quality of the supernatant. The supernatant liquid enters the SBR reactor after the ammonia nitrogen is blown off by air, and the organic matter in the wastewater is degraded by aerobic microbial treatment, and the nitrogen is denitrified by nitrification and denitrification bacteria. The time allocation for each stage of each operation cycle is as follows: water intake for 1 hour, initial aeration for 6 hours, static stirring for 4 hours, re-aeration for 4 hours, sedimentation and drainage for 2 hours. The volume load in the reactor is controlled at 0.3-0.5kgCOD Cr / (m 3 · d), the dissolved oxygen in the water during the aeration stage is controlled at 2-...

Embodiment 2

[0045] Inject 60L of fresh landfill leachate from the urban domestic waste landfill in Dalian into the reaction tank, add coagulant according to the dosage of 135g / L (leachate), stir for 120min, let it stand for 30min, and analyze the water quality of the supernatant . The supernatant liquid enters the SBR reactor after the ammonia nitrogen is blown off by air, and the organic matter in the wastewater is degraded by aerobic microbial treatment, and the nitrogen is denitrified by nitrification and denitrification bacteria. The time allocation for each stage of each operation cycle is as follows: water intake for 1 hour, initial aeration for 8 hours, static stirring for 6 hours, re-aeration for 6 hours, and sedimentation and drainage for 2 hours. The volume load in the reactor is controlled at 0.3-0.5kg COD Cr / (m 3 · d), the dissolved oxygen in the water during the aeration stage is controlled at 2-4mg / L. Table 3 shows the analysis results of raw water and main pollutant ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com