Environment-friendly type thermostable rubber high-strength concrete

A high-strength concrete and high-temperature-resistant technology, applied in the field of concrete, can solve problems such as corrosion, potential safety hazards of concrete structures, and threats to the durability of concrete, and achieve the effects of reducing production costs, maintaining complete appearance, and low prices

Inactive Publication Date: 2007-10-31

GUANGDONG UNIV OF TECH

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention is not limited to the following examples.

[0018] Use 42.5PII cement, medium sand M=3.1, 5-30mm granite gravel to prepare environment-friendly high-temperature-resistant rubber high-strength concrete, 1m 3 The dosage of each component in high-strength concrete, the slump of the fresh mix, the strength at room temperature, and the electric flux are shown in Table 1 and Table 2:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an environment-friendly type fire resistant rubber high-strength concrete, which comprises the following steps: allocating 280-310kg cement, 180-240kg powdered ore, 30-46kg silica flour, 5-15kg reclaimed rubber powder, 110-125kg water, 700-740kg sand and 1060-1168kg stone as raw material; compositing naphthalenesulfonate and plastic reinforcer as complexing additive with the density at 30%; counting 3. 5%-5. 0% of the weight sum of the cement, powdered ore and silica flour cementing material; adding; bedding-in the high-strength concrete with flowability at 230mm and 28 days compression strength at 100MPa; setting the electric flux between 283 and 304 coulomb and the diffusion depth of chloride ion at 0mm. This invention possesses good exterior.

Description

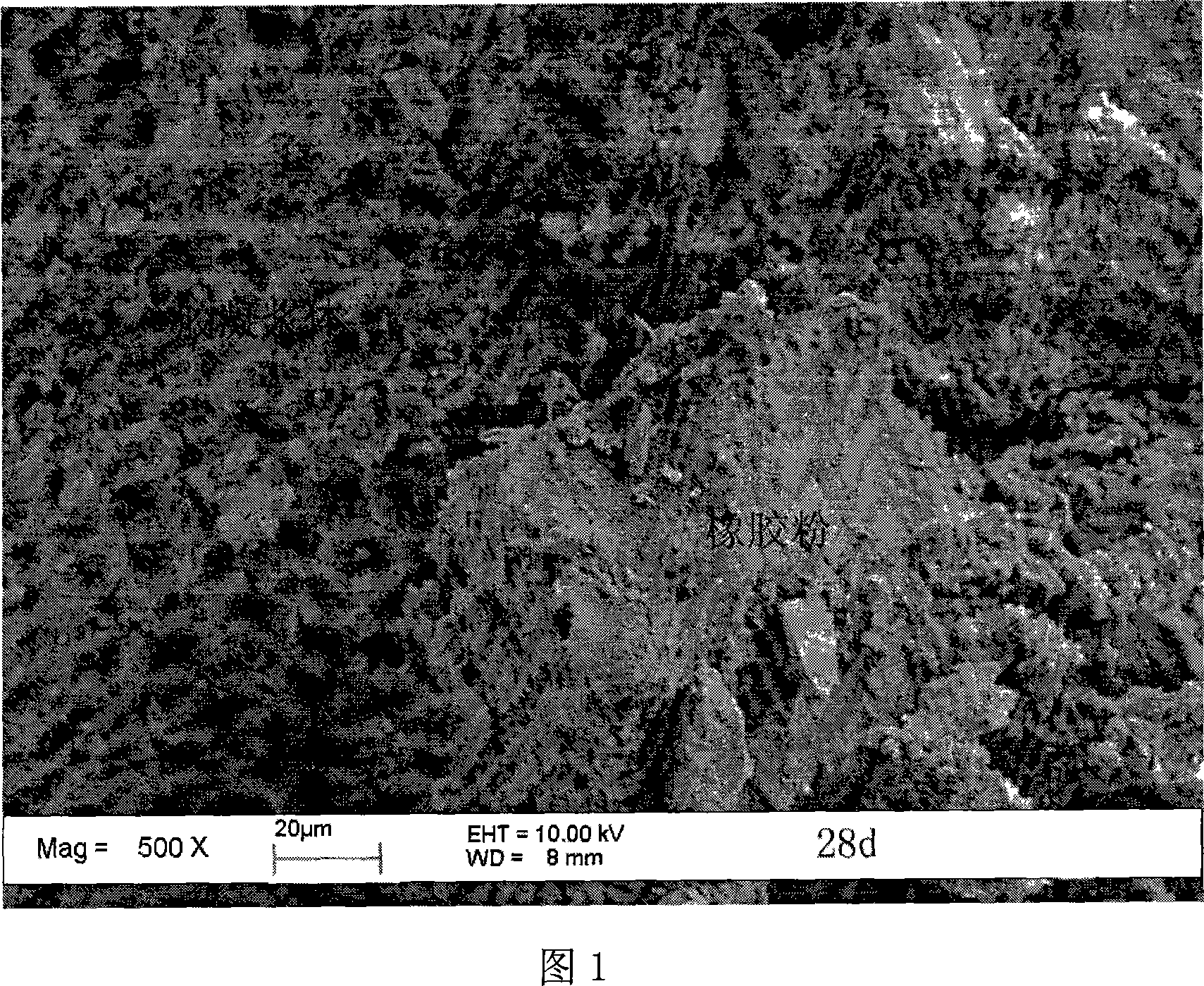

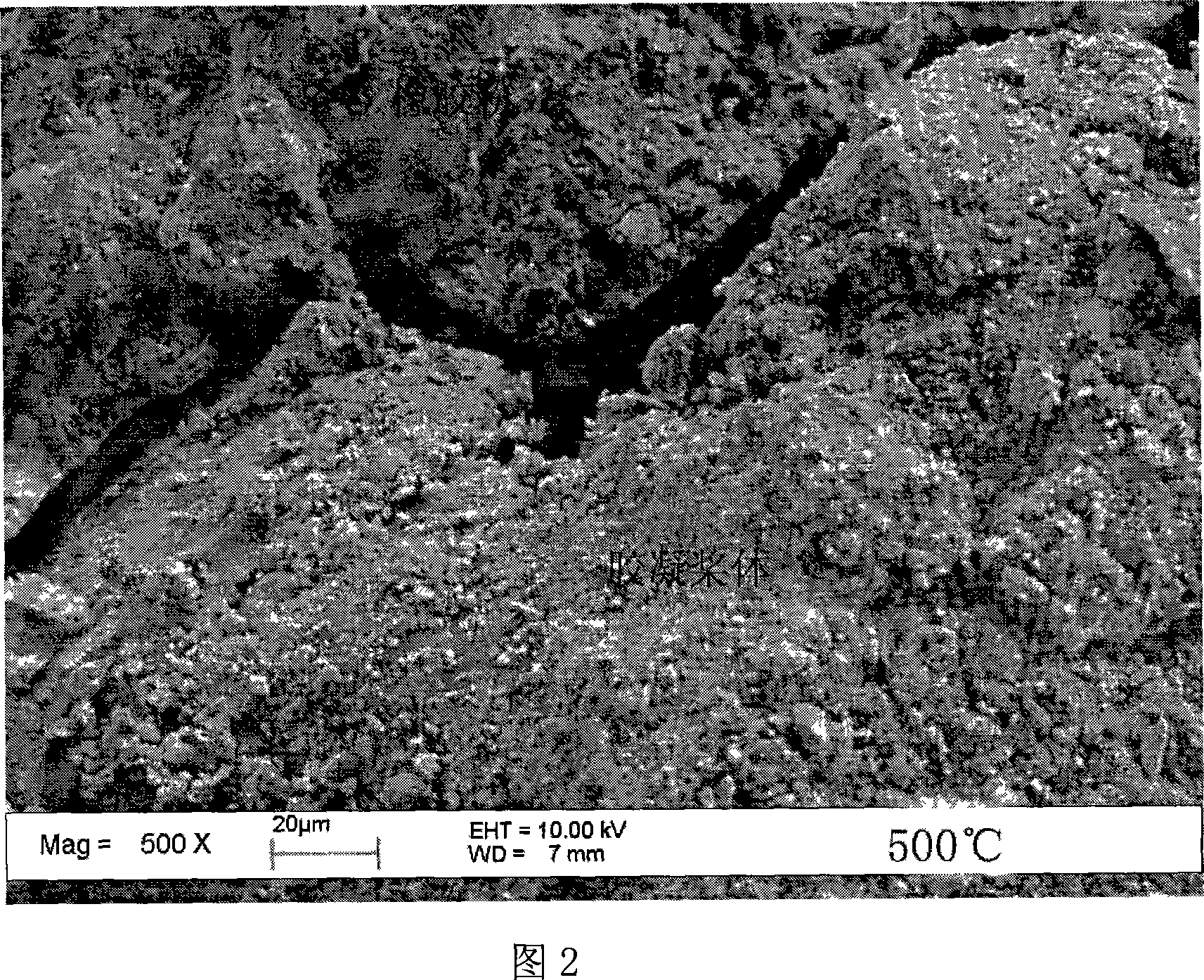

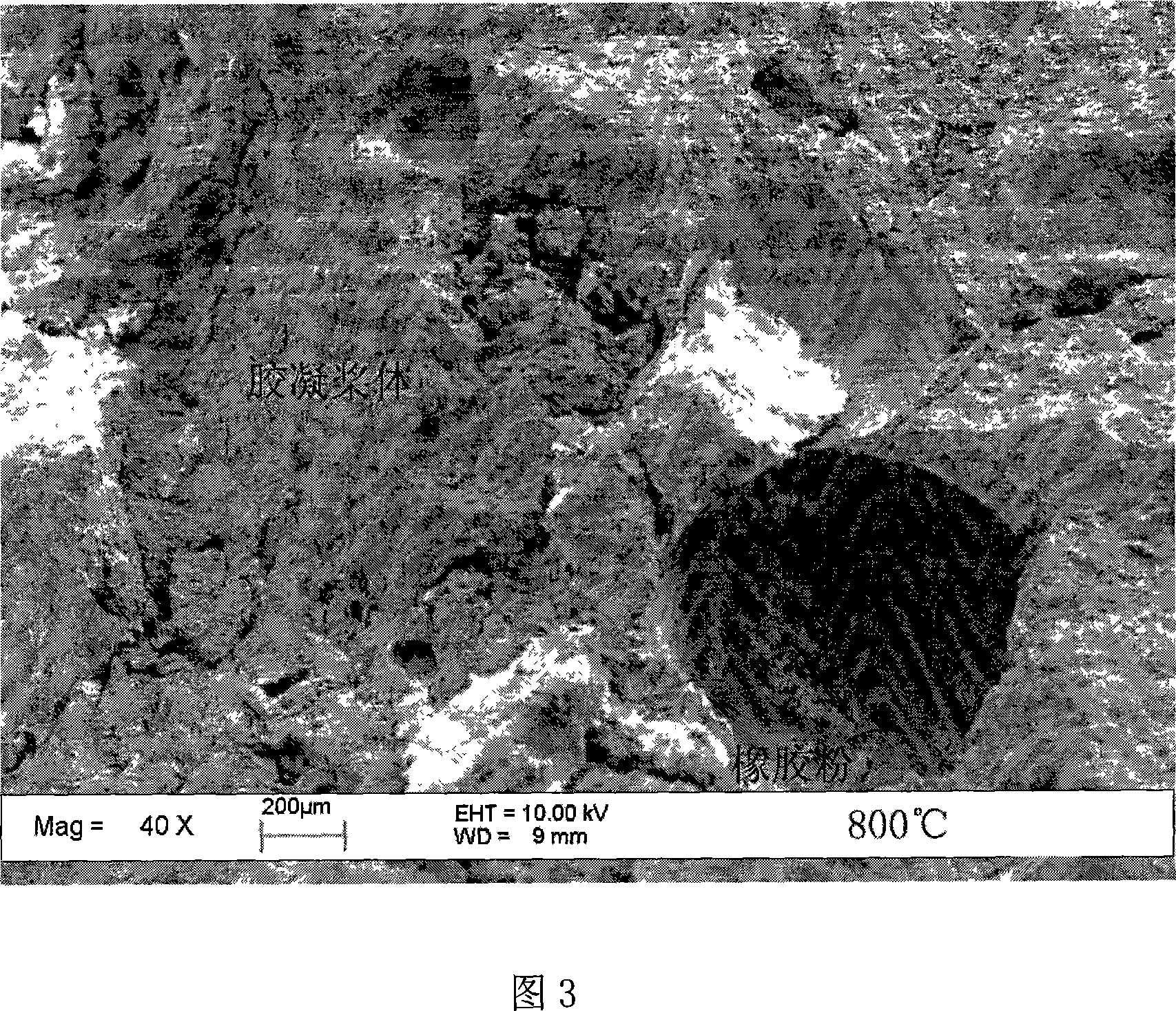

technical field [0001] The invention relates to the field of concrete, and more particularly relates to an environment-friendly high-temperature-resistant rubber high-strength concrete. Background technique [0002] High-strength concrete is an important component of modern super high-rise and super long-span buildings. High-strength concrete consists of six main basic materials, including: cement, active mineral admixtures, gravel, sand, water reducer and water. With the development of urbanization in our country, buildings tend to be super high-rise and super-long-span, so the amount of high-strength concrete will inevitably increase. Because high-strength concrete is easy to cause burst damage under the action of fire and high temperature, once the burst occurs, the protective layer of the steel bar will lose its effect, and the steel bar will be directly exposed to high temperature. Since the steel bar will soften at about 300 ° C, coupled with the shrinkage of the cros...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/00C04B14/04C04B16/04C04B14/06C04B24/20

CPCC04B28/02Y02W30/91C04B14/02C04B14/06C04B18/12C04B18/22C04B24/226C04B2103/30

Inventor 李丽娟刘锋谢伟锋陈智泽陈应钦

Owner GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com