Preparation method of polyisobutylene

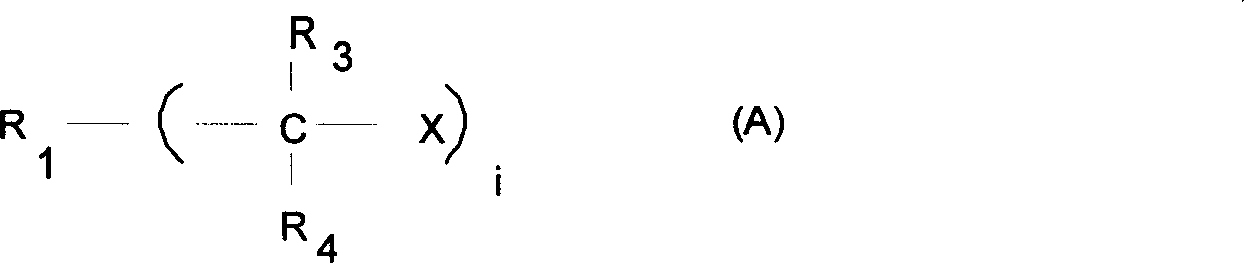

A technology of polyisobutylene and isobutylene, which is applied in the field of preparing polyisobutylene, can solve problems such as unavoidable internal double bond products, and achieve the effect of simplifying the reaction process and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Under the protection of high-purity nitrogen, add 0.15 mmol of methanol and 1.5 mmol of titanium tetrachloride to 25 mL of isobutene / hexane / dichloromethane monomer solution (the concentration of isobutene is 1.5 mol / L) to initiate polymerization, and react at -30 ° C After 10 min, add 1 mL of 0.1 g / L NaOH / ethanol solution to terminate the reaction, add ethanol to precipitate the polymer, and repeatedly wash with ethanol until it becomes clear and transparent. The monomer conversion rate was 73%, and a highly reactive polyisobutene with a number average molecular weight of 1400, a molecular weight distribution index of 1.6, an α-double bond content of 70%, and a tertiary chlorine end group content of 30% was obtained.

Embodiment 2

[0023] Under the protection of high-purity nitrogen, add 0.4 mmol of methanol and 1.5 mmol of titanium tetrachloride to 25 mL of isobutene / hexane / dichloromethane monomer solution (the concentration of isobutene is 1.5 mol / L) to initiate polymerization, at -30 ° C After reacting for 60 min, add 1 mL of 0.1 g / L NaOH / ethanol solution to terminate the reaction, add ethanol to precipitate the polymer, and repeatedly wash with ethanol until it becomes clear and transparent. The monomer conversion rate was 95.7%, and a highly reactive polyisobutene with a number average molecular weight of 1400, a molecular weight distribution index of 1.5, an α-double bond content of 87%, and a tertiary chlorine end group content of 13% was obtained.

Embodiment 3

[0025] Under the protection of high-purity nitrogen, add 0.45 mmol of isopropanol and 3.0 mmol of titanium tetrachloride to 25 mL of isobutene / hexane / dichloromethane monomer solution (the concentration of isobutene is 1.5 mol / L) to initiate polymerization, -30 ° C After reacting for 60 min, add 1 mL of 0.1 g / L NaOH / ethanol solution to terminate the reaction, add ethanol to precipitate the polymer, and wash with ethanol repeatedly until it becomes clear and transparent. The monomer conversion rate was 27.3%, and a highly reactive polyisobutene with a number average molecular weight of 1600, a molecular weight distribution index of 2.3, an α-double bond content of 79%, and a tertiary chlorine end group content of 21% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com