Scaffold material capable of inducing biological hard tissue or soft tissue

A scaffold material and hard tissue technology, used in prostheses, dental implants, coatings, etc., can solve problems such as the inability to meet the osseointegration state, achieve excellent induction and implantation, improve external force, and be easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

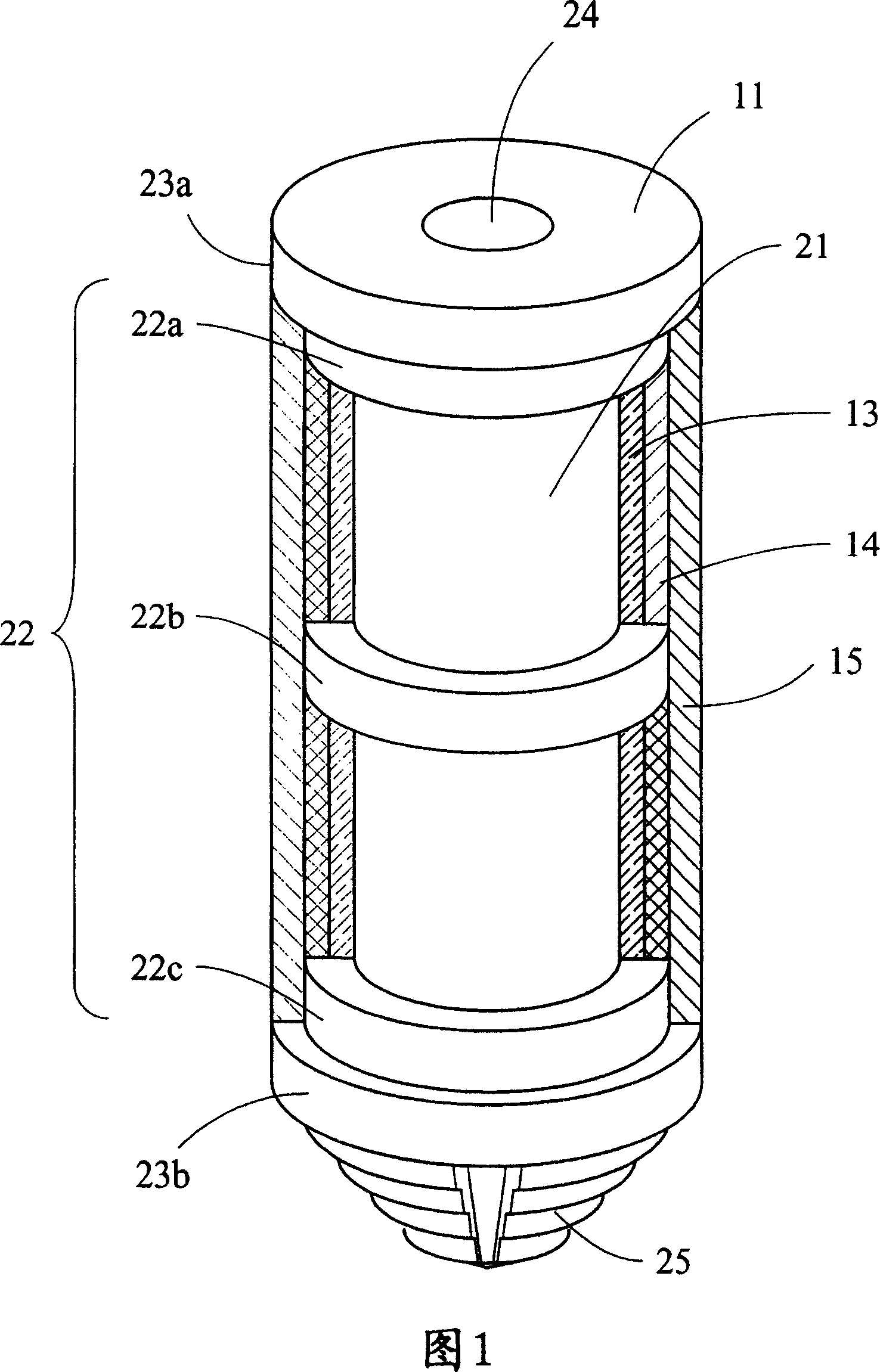

[0111] The artificial tooth root 40 shown in Fig. 5 is produced. Here, the internal thread formed on the inner surface of the introduction hole 44 is not formed. The base material 41 is formed by filling a mold with a titanium metal wire with a diameter of 80 μm and sintering it so that the diameter of the flange portion 43 is 4 mm, the diameter of the introduction hole 44 is 2 mm, the length is 3 mm, and the average hole diameter is 80 μm.

[0112] In addition, the cell induction layer 42 is wound with a metal nonwoven fabric formed by entangling titanium metal wires with a diameter of 80 μm so that the average pore diameter is 200 μm.

[0113] Furthermore, a titanium rod was installed in the introduction hole 44, and they were bonded by vacuum sintering to form an artificial tooth root. The base material 41 of the artificial tooth root 40 thus formed corresponds to the bonding layer of the present invention, and the cell-inducing layer 42 corresponds to the metal fiber laye...

Embodiment 2

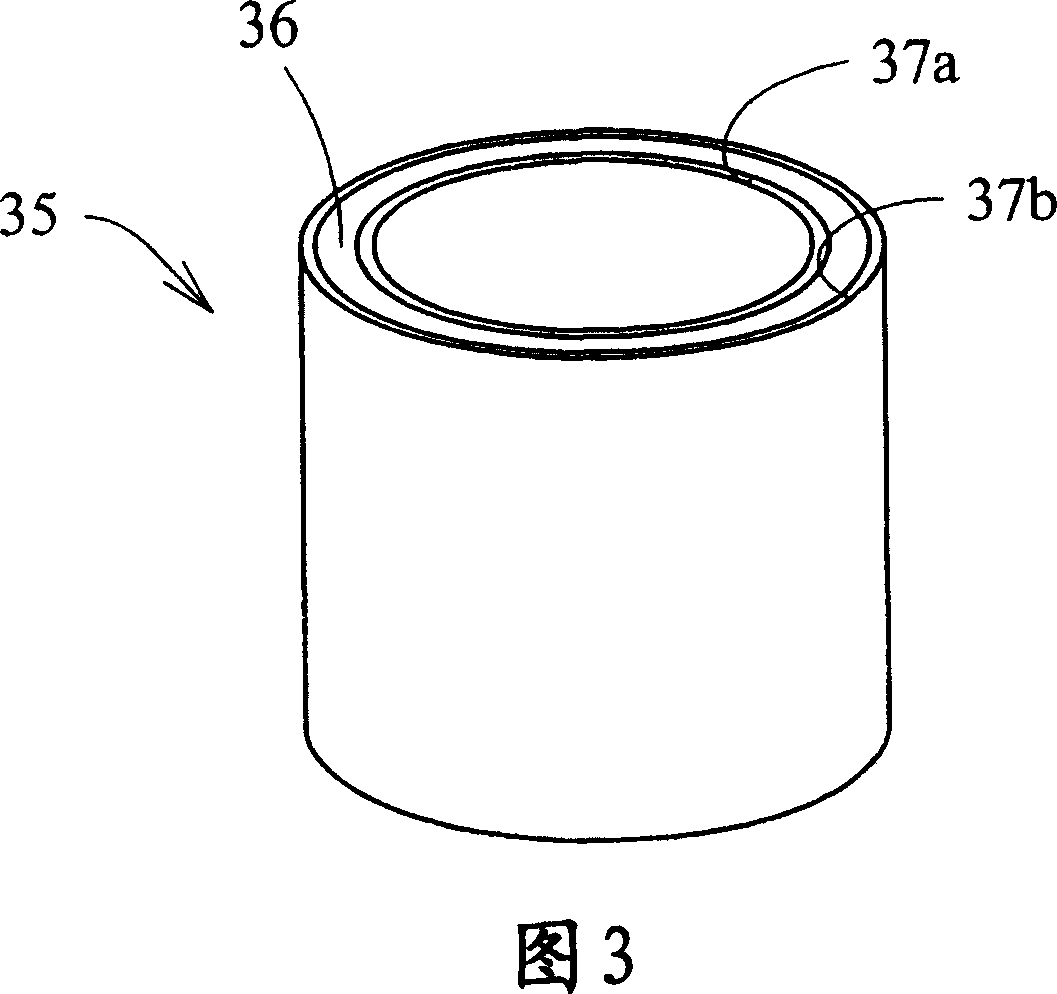

[0150] A culture chassis in which the titanium fiber mesh of Example 1 was inserted into a bottomed cylindrical titanium frame was produced. Set as Example 2.

[0151] [Comparative example 1]

[0152] A plastic case made of a conventionally known flat plastic dish was used as Comparative Example 1.

[0153] Fibroblasts in Examples 1 and 2 and Comparative Example 1 were seeded, soaked in a culture solution, and cultured for 2 weeks. Fig. 17 shows the amount of collagen produced by fibroblasts at this time. It can be seen from the figure that when cultured with the culture chassis (Example 1) used in the culture method of the present invention, the production of collagen was increased by 1.4 times compared with the usual plastic box. Furthermore, when the culture was carried out in the culture base plate (Example 2) equipped with a rack, the production of collagen was increased by 1.8 times compared with the usual plastic box.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com