Computer hard disk aluminium base material parts chemical nickeling technology

A computer hard disk, electroless nickel plating technology, applied in the direction of liquid chemical plating, metal material coating process, superimposed layer plating, etc., can solve the problems of failing to meet environmental protection requirements and low cleanliness of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

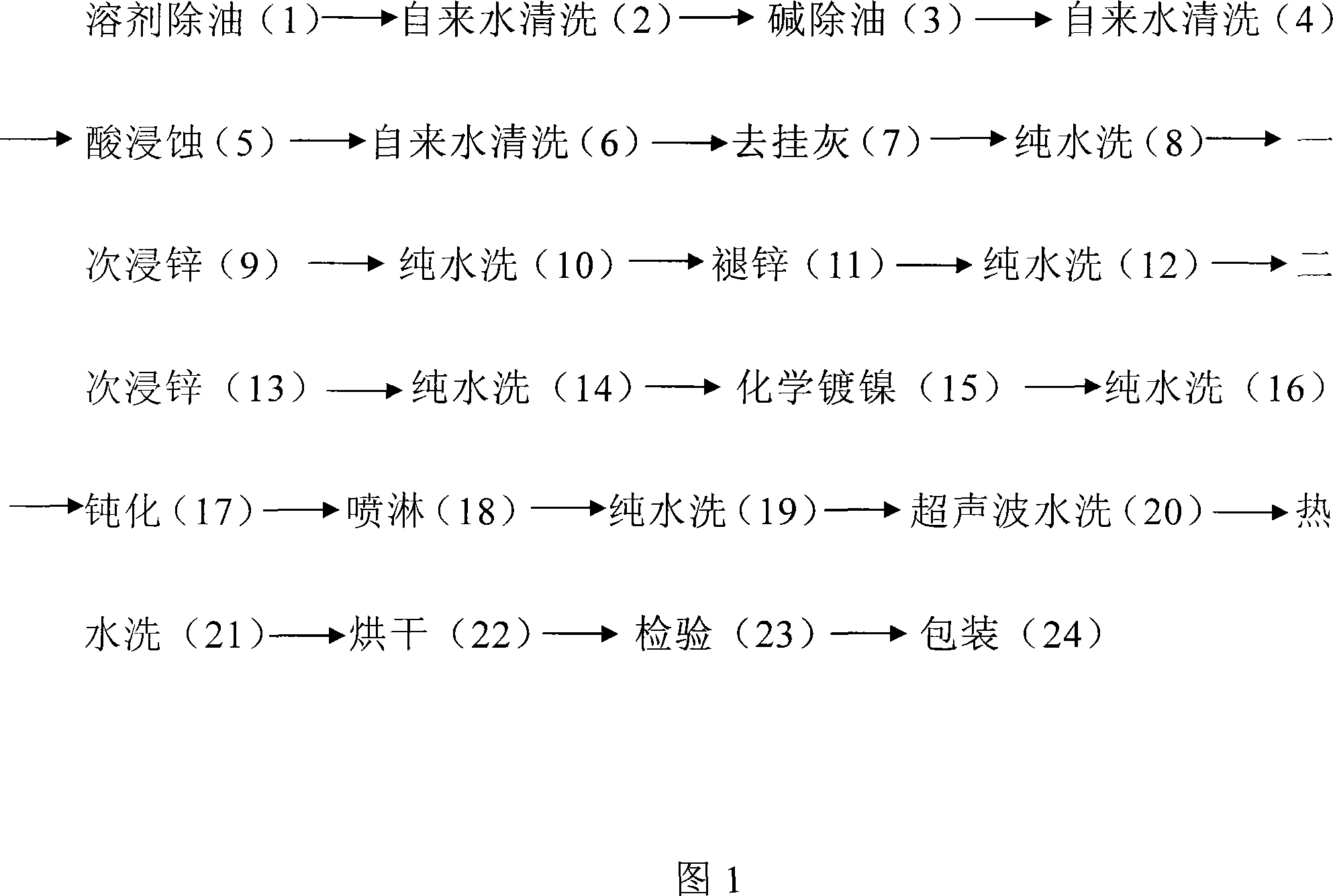

[0030] 1. Electroless nickel plating process for computer hard disk aluminum substrate components, including:

[0031] a. Solvent degreasing: soak the parts in a degreasing agent composed of naphtha at room temperature for 5-10 minutes, and use emulsification to degrease the parts; and use a filter pump to filter impurities in the degreasing liquid to improve Degreasing effect;

[0032] b. Water washing: use tap water to clean the degreasing agent on the surface of the parts;

[0033] c. Alkali degreasing: Heat the alkali degreasing solution consisting of 1-5 parts of sodium hydroxide and 0.5-2 parts of sodium silicate to 60-70°C, and then soak the parts in the alkali degreasing solution for 20-30 minutes , Use saponification to remove oil from the parts, and use shaking and ultrasonic waves to improve the oil removal effect; the equipment used is a filter pump, an ultrasonic generator, a rocking device, and a temperature control system.

[0034] d. Water washing: wash the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com