Composition of laundry detergent improving touch feel of clothes and manufacturing method thereof

A technology of laundry detergent and composition, which is applied in the field of preparation of laundry detergent composition, and can solve the problems of high preparation cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

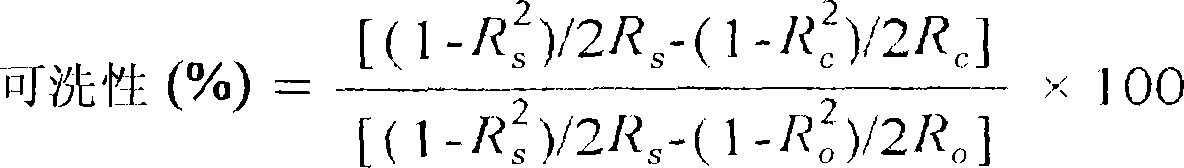

Image

Examples

preparation example Construction

[0027] The present invention also provides a method of making laundry detergent compositions, and preferably low density laundry detergent compositions, without departing from the spirit and scope of the invention. The term "low density" as used herein means that the particles have an apparent density including air bubbles of 0.6 g / ml or less. The present invention provides a process for preparing a laundry detergent composition by drying the laundry detergent composition by heat generated by the neutralization of an acidic component with a basic component without the use of an additional drying step, wherein the process comprises The following steps: (S1) prepare acidic water-soluble polymers and anionic surfactants as acidic components, and prepare alkaline builders as alkaline components; (S2) add 0.1 to 15 parts by weight to the mixer The water-soluble polymer in the acidic form and the anionic surfactant of 5-20 parts by weight and the alkaline builder of 10-70 parts by w...

Embodiment 1

[0030] Embodiment 1 (preparation of coating organic acid)

[0031] Citric acid was used as the organic acid to prepare the coating organic acid. The coating was prepared by mixing 90 kg of anhydrous citric acid with 4 kg of silicon compound polydimethylsiloxane used as a binder component in a mixer for 1 hour, followed by adding and mixing 6 kg of silicon dioxide as a coating component. Apply organic acid.

Embodiment 2 and 3 and comparative example 1 and 2

[0032] Examples 2 and 3 and Comparative Examples 1 and 2 (Preparation of Laundry Detergent Compositions)

[0033] Based on the components and contents listed in Table 1 below, the compositions of Examples 2-3 and Comparative Examples 1-2 were prepared by simply mixing the components using a high-speed mixer. Specifically, the composition is prepared by a conventional method comprising the steps of mixing all components except other additives and coating an organic acid to prepare a granulated powder, followed by mixing the granulated powder with other additives and coating organic acids.

[0034] Content (parts by weight)

Example

comparative example

1

2

1

2

nonionic surface active

agent

8

12

6

10

anionic surfactant

laurylbenzenesulfonic acid

8

4

10

6

Acidic form water soluble

Polyacrylic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com