Control system of HCCI/SI double-mode harmonization press-combustion engine and method therefor

A homogeneous compression ignition and control system technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as complex control algorithm, practical distance, and complex control calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

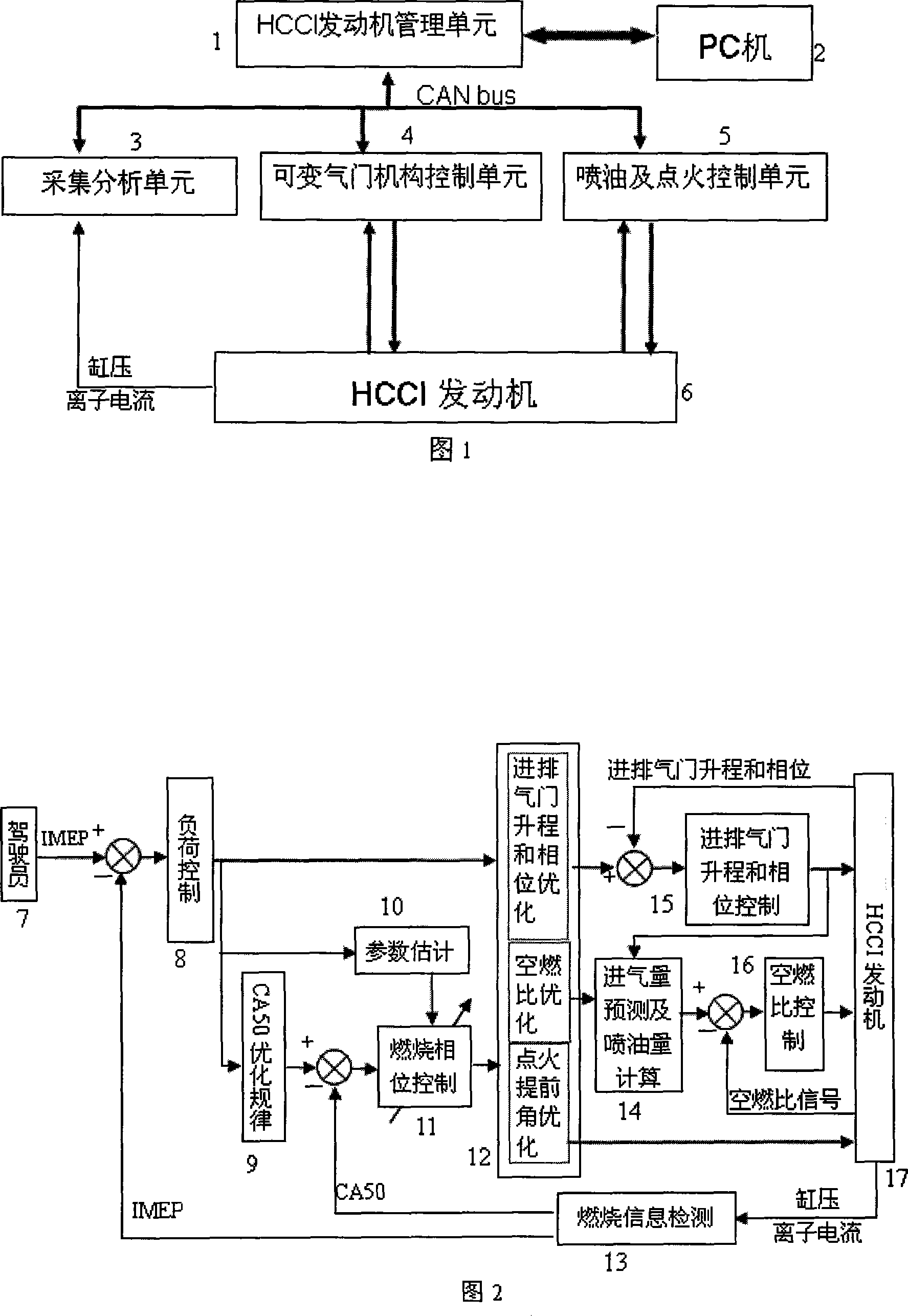

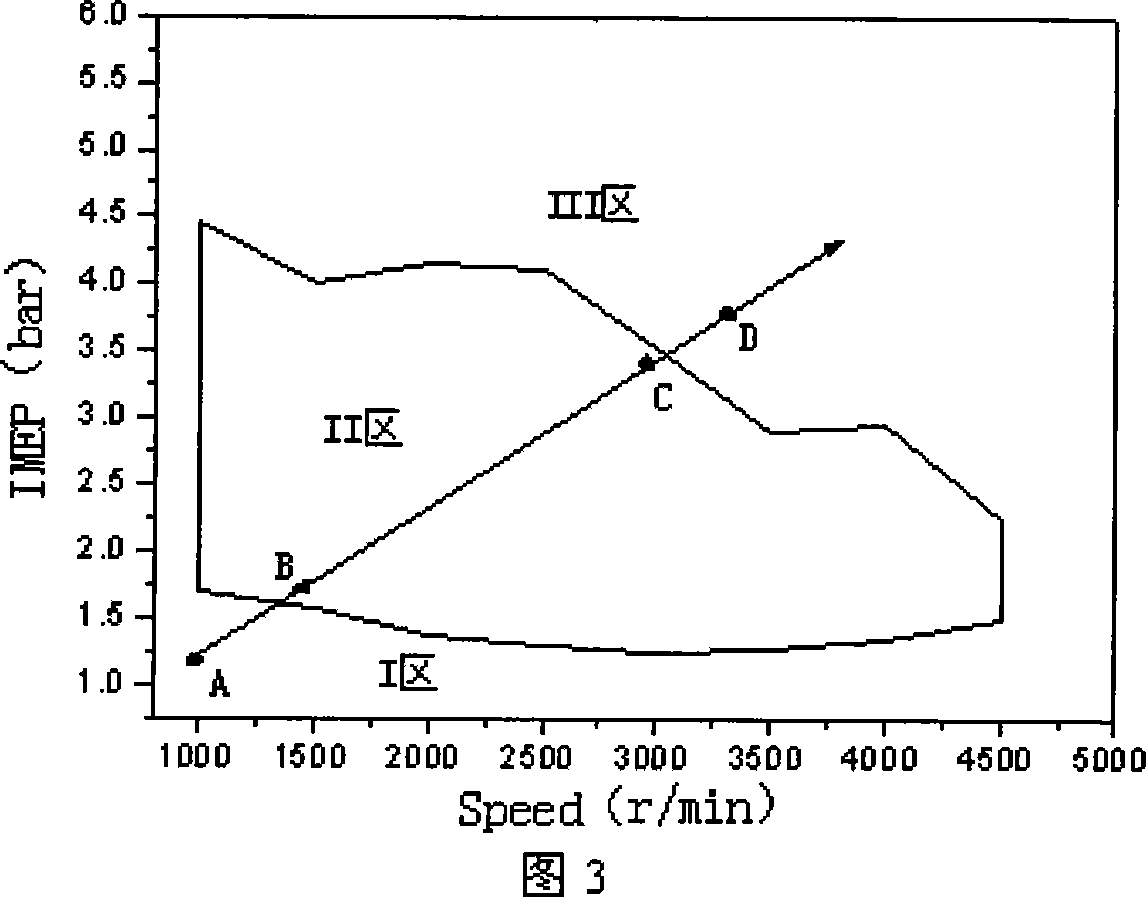

[0030] The present invention will be further described below with reference to the accompanying drawings 1-3 and through specific embodiments. Homogeneous compression ignition is a new type of combustion that is obviously different from spark ignition and burns by flame propagation. The engine applied in the present invention utilizes a fully variable valve mechanism to realize a negative valve overlap angle and obtain a certain amount of high-temperature residual exhaust gas through comprehensive control of valve lift and timing. Sufficient high-temperature residual exhaust gas, during the intake process, mixes with the fresh mixture and heats it. When the piston is compressed to a certain moment near the top dead center, the combustible mixture reaches the self-ignition temperature, multiple points are ignited at the same time, and synchronous combustion releases heat and works. Therefore, the closing time of the intake valve and the state of the mixture in the cylinder dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com