Double platform system for rotary exchange

A dual-stage, base-stage technology, applied in the field of semiconductor manufacturing equipment, can solve problems such as the influence of system positioning accuracy, and achieve the effect of simplifying the structure and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The dual-stage system for rotary exchange of the present invention will be further described in detail below.

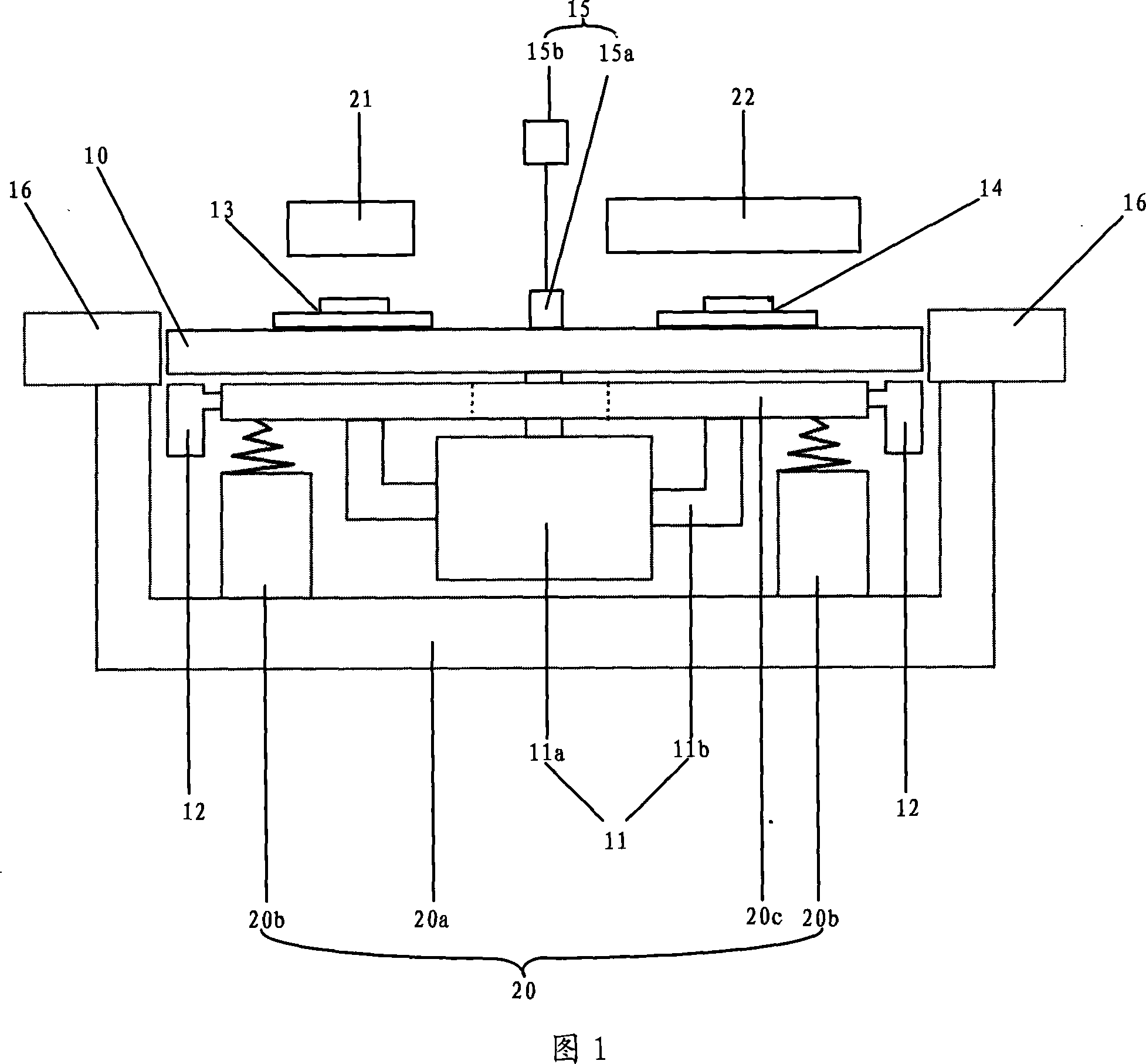

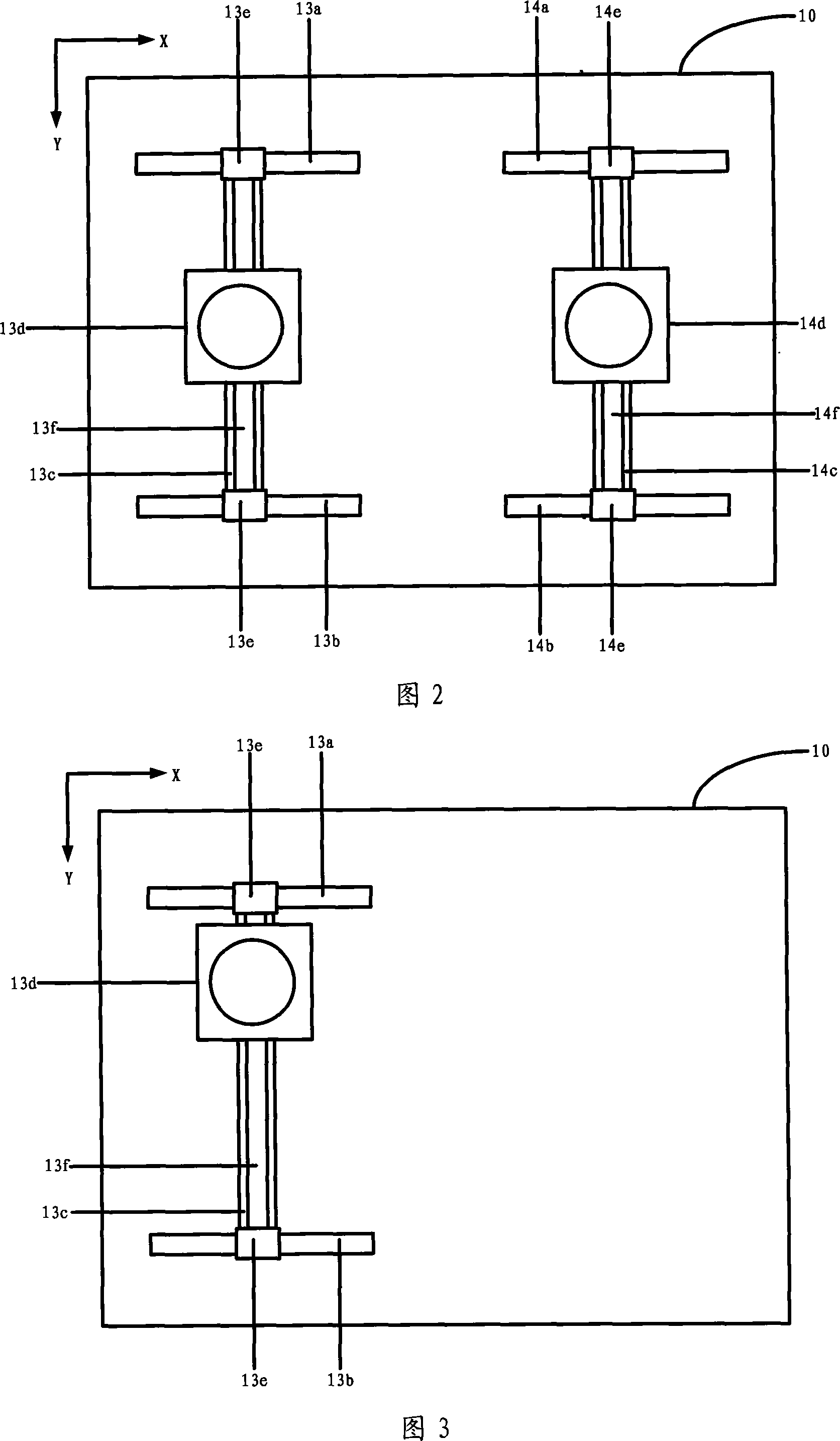

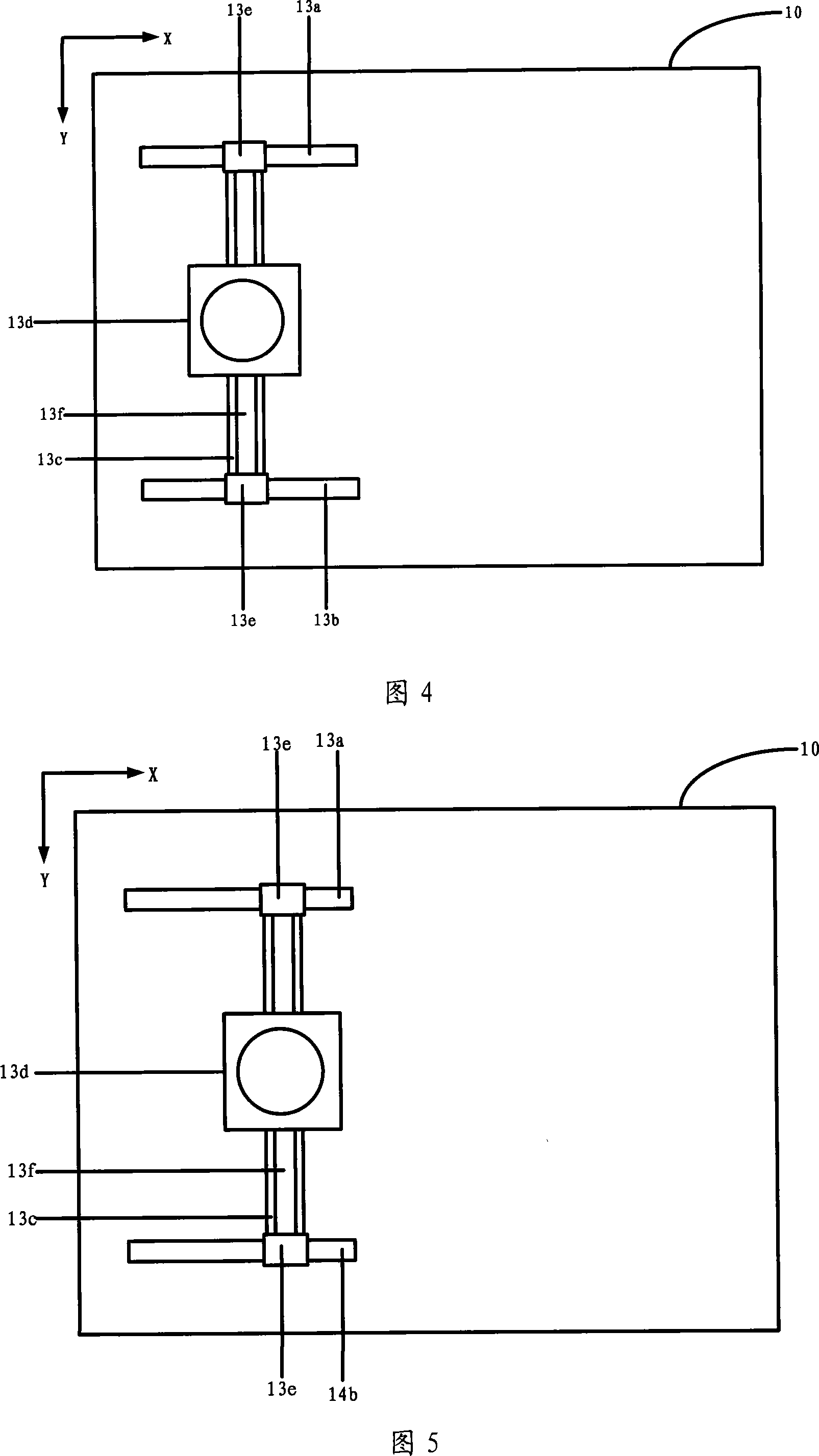

[0042] Referring to Fig. 1, it shows the schematic structural diagram of the first embodiment of the dual-stage system of rotary exchange of the present invention, as shown in the figure, the dual-stage system of rotary exchange is used in a photolithography machine, and the rotary The exchanged dual-table system includes a base 10, a base driving device 11, a base locking unit 12, a first workbench 13, a second workbench 14, a control module 15, and a deceleration module 16, wherein the lithography machine It includes a main frame 20 , an alignment measurement module 21 , an exposure module 22 , a loading module (not shown), and a loading module (not shown).

[0043]The main frame 20 includes a U-shaped bracket 20a, a plurality of shock-absorbing structures 20b evenly distributed on the bottom of the U-shaped bracket, and a support platform 20c arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com