Self-test micromechanical thermoelectric pile bioreaction heat detector and its preparing method

A thermopile, micromechanical technology, used in the manufacture/processing of thermoelectric devices, thermoelectric devices using only the Peltier or Seebeck effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

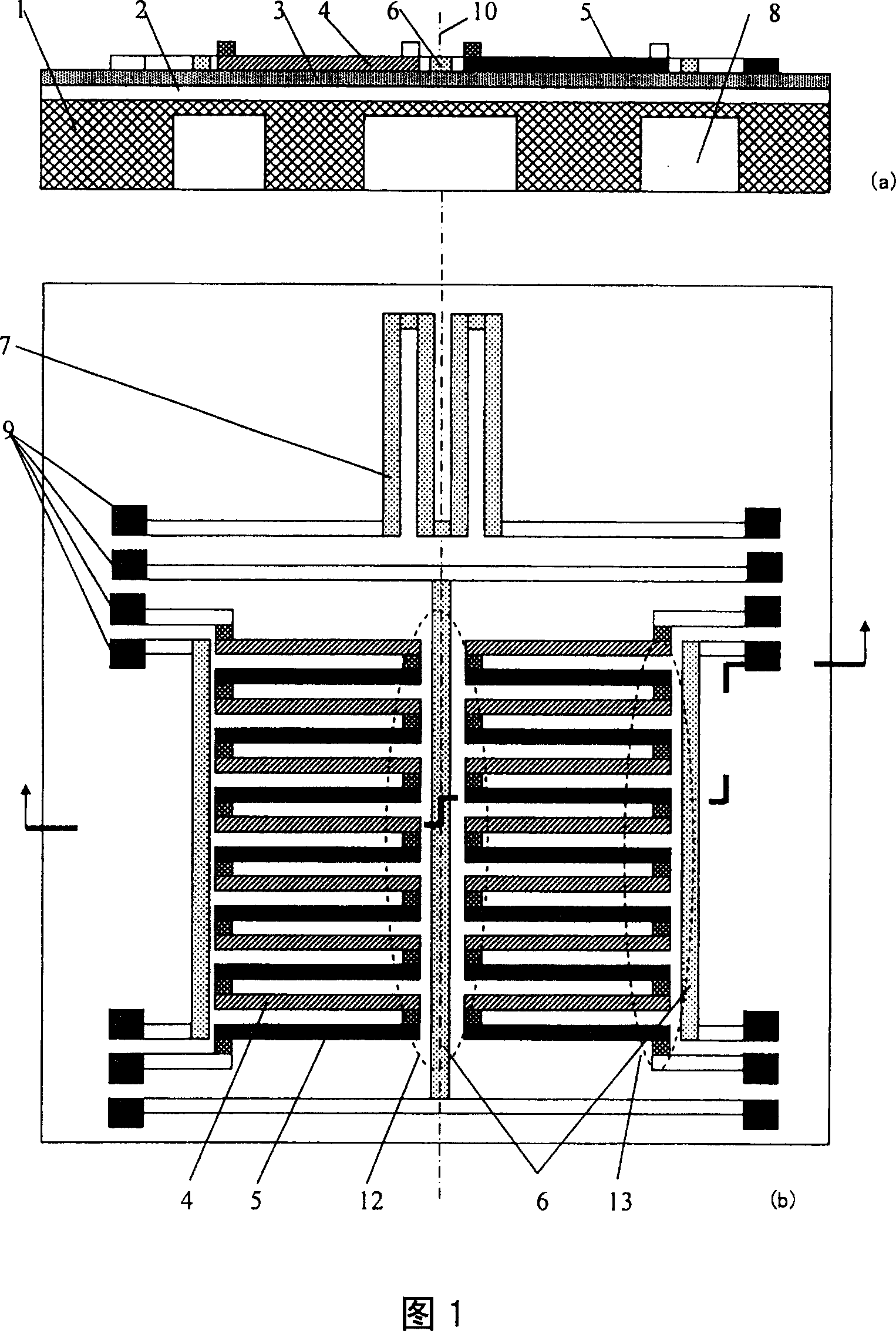

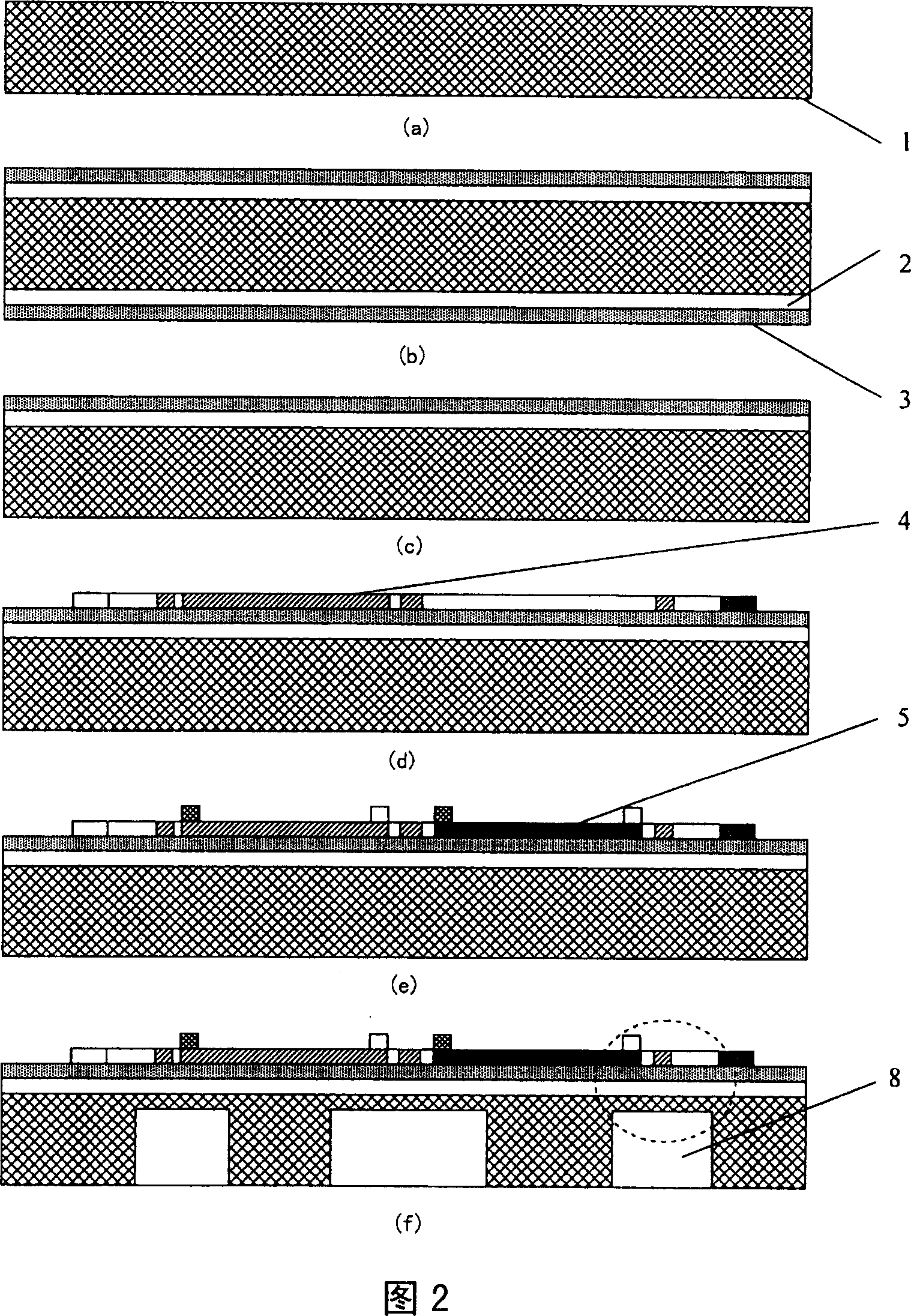

[0030] Please refer to FIG. 1 a and FIG. 1 b , which are respectively a side view and a plan view of the self-checking micromechanical thermopile bioreaction heat detector of the present invention. The micromechanical thermopile bioreaction thermal detector capable of self-checking of the present invention comprises a silicon substrate 1, on one side of the silicon substrate 1 there are silicon dioxide 2 and a silicon nitride insulating layer 3 in sequence; on the silicon nitride insulating layer 3, two groups of thermocouples 4, 5, self-checking element 6 and preheating coil 7, which are composed of two different metals connected end to end, are arranged side by side, and the whole has a symmetrical structure. The metal that forms thermocouple 4,5 can be platinum (Pt) and nickel (Ni) for example, and self-check element 6 and preheating coil 7 can be the third kind of metal except above-mentioned two kinds of metals, and can adopt the same step After the process is completed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com