Polymer grafted carbon black composite resistance type thin film humidity sensor and its production method

A technology of grafting carbon black and composite resistance, applied in the direction of material resistance, can solve the problems of easy dissolution and loss of polymer sensitive materials, poor stability, poor response, etc., to reduce agglomeration phenomenon, wide resistance change range, The effect of increased spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

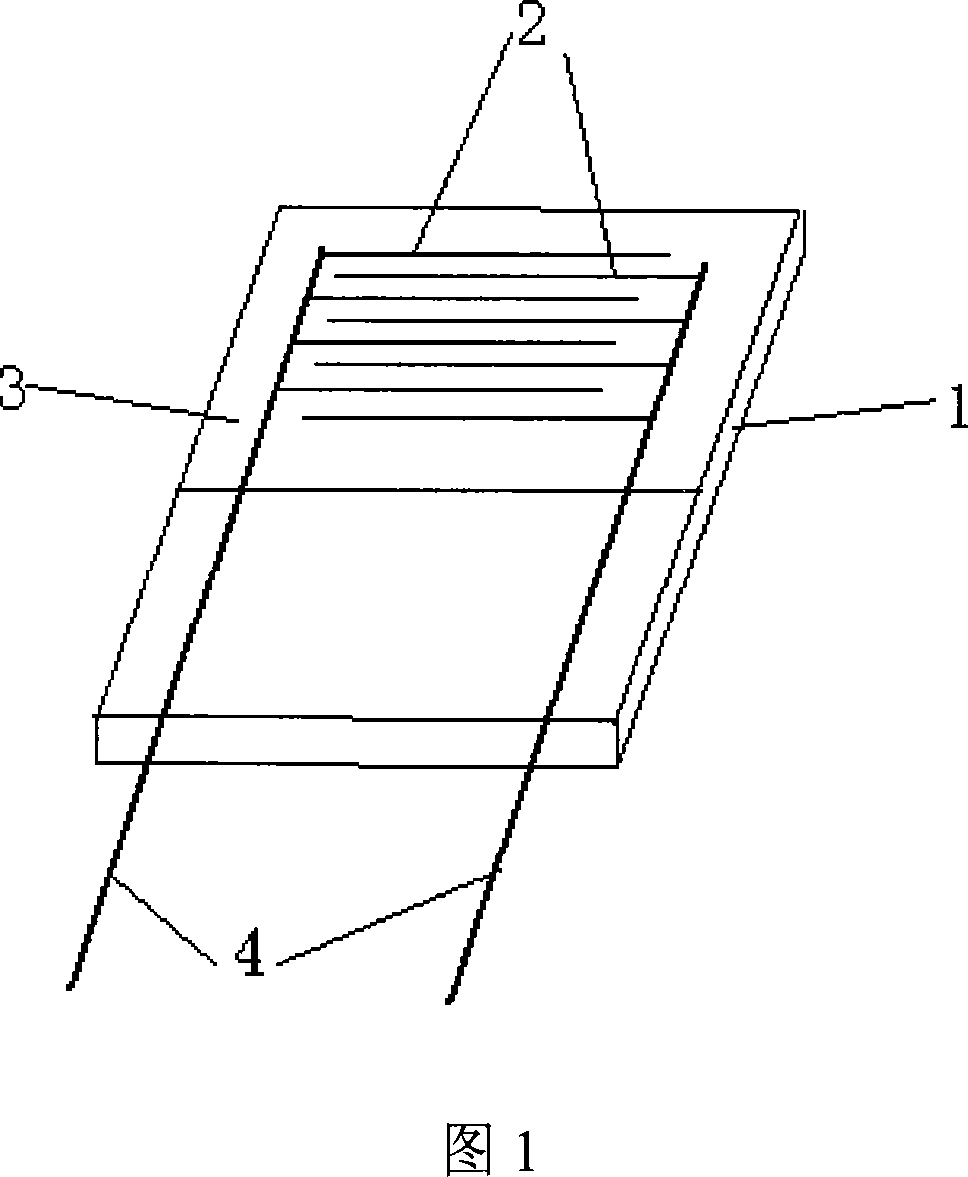

[0029] 1) Soak and clean the glass-ceramics substrate with interdigitated gold electrodes on the surface photoetched and evaporated with absolute ethanol and acetone, and dry for later use;

[0030] 2) In the presence of 4-hydroxyl-2,2,6,6-tetramethylpyridine nitroxide free radicals, benzoyl peroxide initiator is used to initiate bulk polymerization of 4-vinylpyridine, under argon atmosphere at 125 After reacting at ℃ for 15 hours, the obtained product was precipitated, washed by filtration, and dried in vacuum to obtain a polymer terminated by nitroxide radicals;

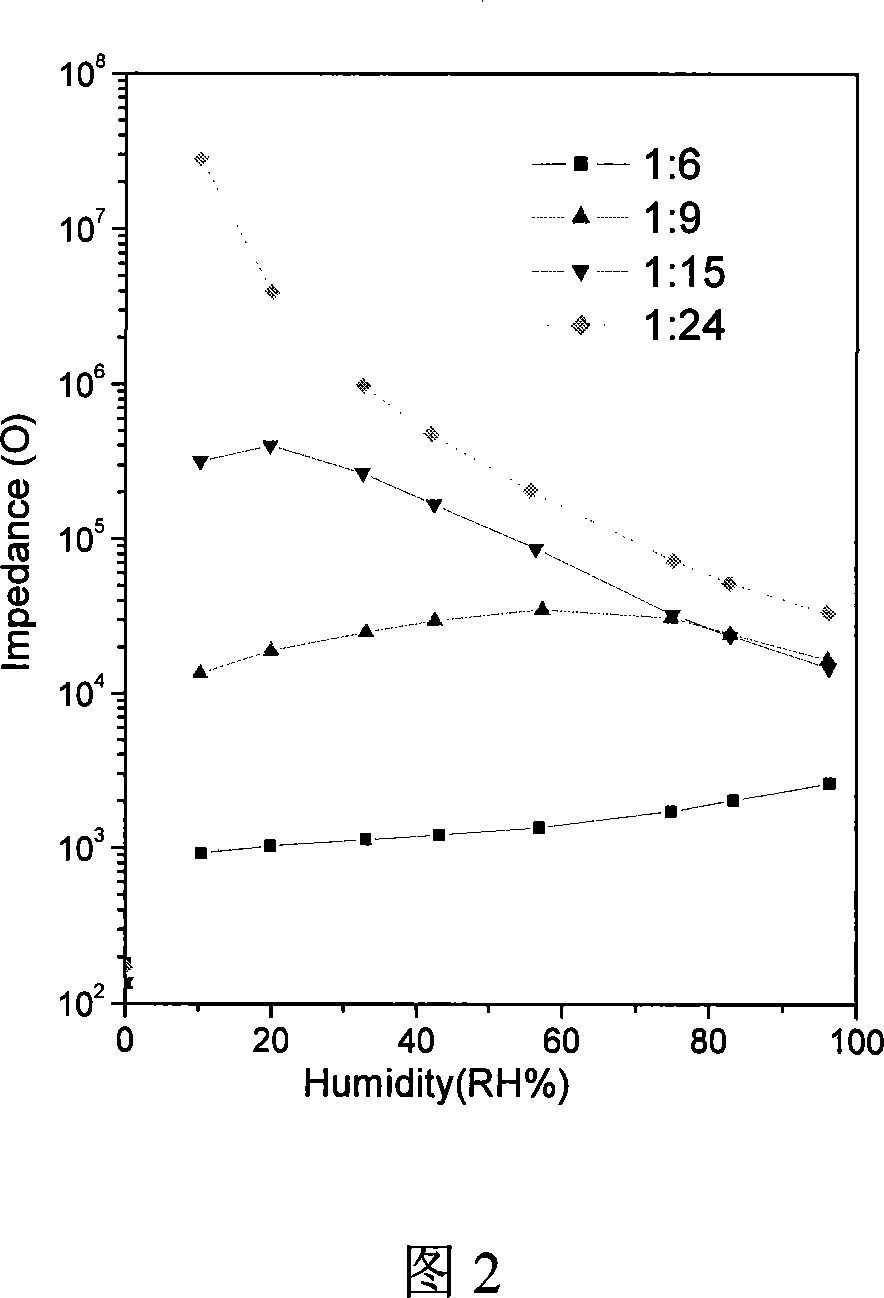

[0031] 3) Dissolve the nitroxide-terminated polymer in N,N-dimethylformamide, add carbon black, the mass ratio of carbon black to polymer is 1:6, and react at 125°C for 2h under an argon atmosphere , and then precipitated with ether, filtered, washed and vacuum-dried to obtain a poly-4-vinylpyridine-grafted carbon black composite.

[0032] 4) The poly 4-vinylpyridine grafted carbon black composite and 1,4-dibromob...

Embodiment 2

[0035] 1) Electrode cleaning is the same as in Example 1

[0036] 2) In the presence of 4-hydroxyl-2,2,6,6-tetramethylpyridine nitroxide free radicals, benzoyl peroxide initiator is used to initiate bulk polymerization of 4-vinylpyridine, under argon atmosphere for 90 After reacting at ℃ for 40 hours, the obtained product was precipitated, filtered and washed, and vacuum-dried to obtain a nitrogen-oxygen radical-terminated polymer;

[0037] 3) Dissolve the polymer terminated by nitrogen and oxygen radicals in N,N-dimethylformamide, add carbon black, the mass ratio of carbon black to polymer is 1:24, and react at 90°C under an argon atmosphere 15h, and then precipitated with ether, filtered, washed and dried in vacuum to obtain poly-4-vinylpyridine-grafted carbon black composite.

[0038] 4) The poly 4-vinylpyridine grafted carbon black composite and 1,4-dibromobutane are dispersed in N,N-dimethylformamide by ultrasonic vibration, and the poly 4-vinylpyridine grafted carbon bl...

Embodiment 3

[0041] 1) Electrode cleaning is the same as in Example 1

[0042]2) In the presence of 4-hydroxyl-2,2,6,6-tetramethylpyridine nitroxide free radicals, benzoyl peroxide initiator is used to initiate bulk polymerization of 4-vinylpyridine, under argon atmosphere at 125 After reacting at ℃ for 29 hours, the obtained product was precipitated, washed by filtration, and dried in vacuum to obtain a polymer terminated by nitroxide radicals;

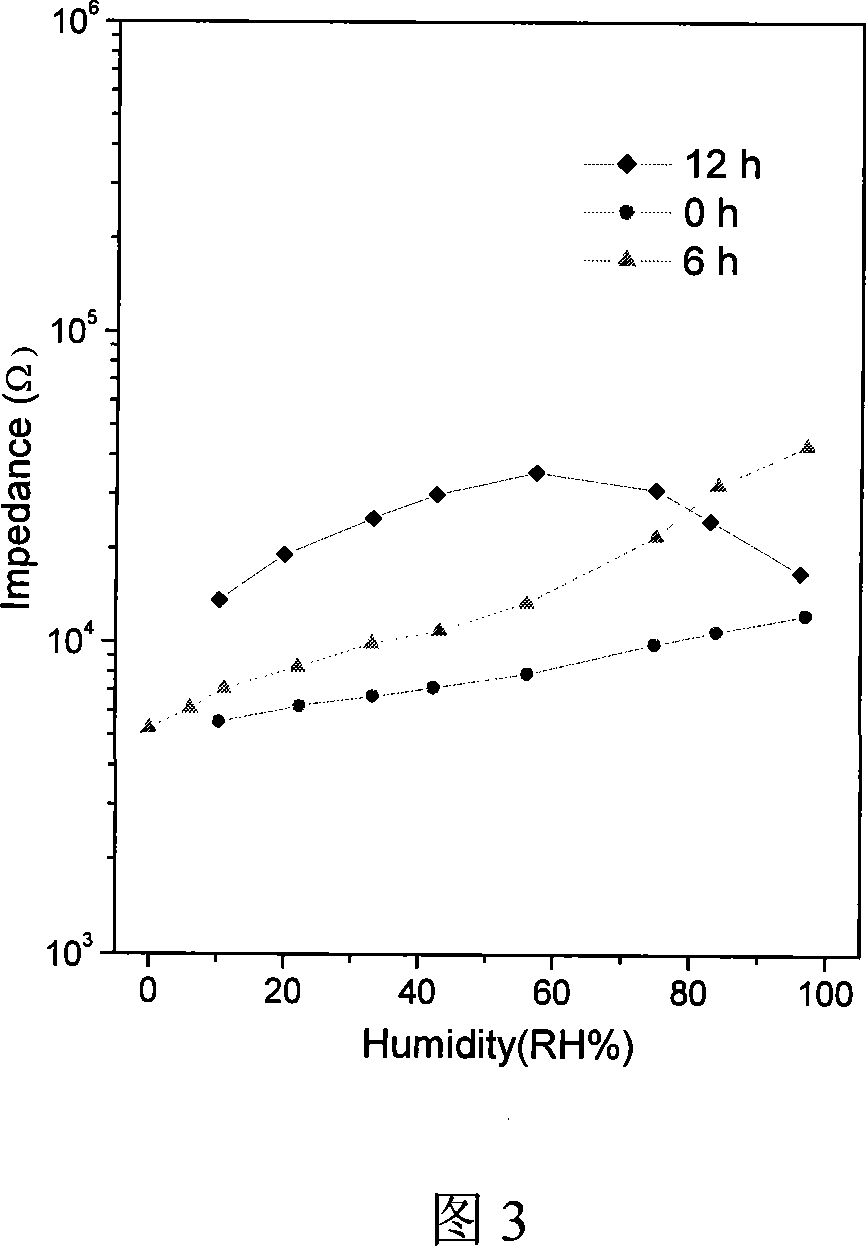

[0043] 3) Dissolve the obtained nitroxide-terminated polymer in N,N-dimethylformamide, add carbon black, the mass ratio of carbon black to polymer is 1:9, and react at 125°C under an argon atmosphere 12h, and then precipitated with ether, filtered, washed and dried in vacuum to obtain poly-4-vinylpyridine-grafted carbon black composite.

[0044] 4) The poly 4-vinylpyridine grafted carbon black composite and 1,4-dibromobutane are dispersed in N,N-dimethylformamide by ultrasonic vibration, and the poly 4-vinylpyridine grafted carbon black composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interdigital width | aaaaa | aaaaa |

| Interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com