Semiconductor package having non-ceramic based window frame

A window frame and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device components, light guides, etc., can solve problems such as interference with die installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

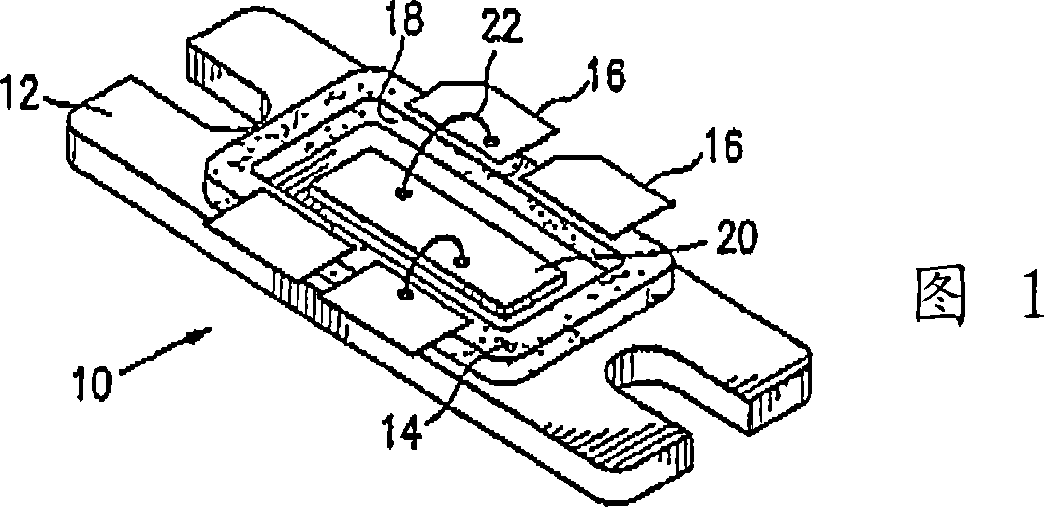

[0024] FIG. 1 shows a semiconductor package 10 according to the present invention. The package 10 in FIG. 1 includes a heat sink flange 12 of elongated, planar, generally planar configuration with a window frame 14 mounted thereon. A plurality of lead wires 16 are mounted on the window frame 14 opposite to the flange 12 . The window frame 14 has an opening 18 therein exposing a portion of the flange 12 . Semiconductor die 20 is mounted in opening 18 of flange 12 and is electrically coupled to leads 16 . Such electrical coupling may be accomplished with wire bonds 22, two of which are shown in FIG. 1 for illustration. A single die is shown in Figure 1 for illustration purposes, multiple dies may be mounted within the opening if desired. A cover (not shown) may be mounted over the leads 16 so as to extend over and surround the opening 18 and the contained die 20 .

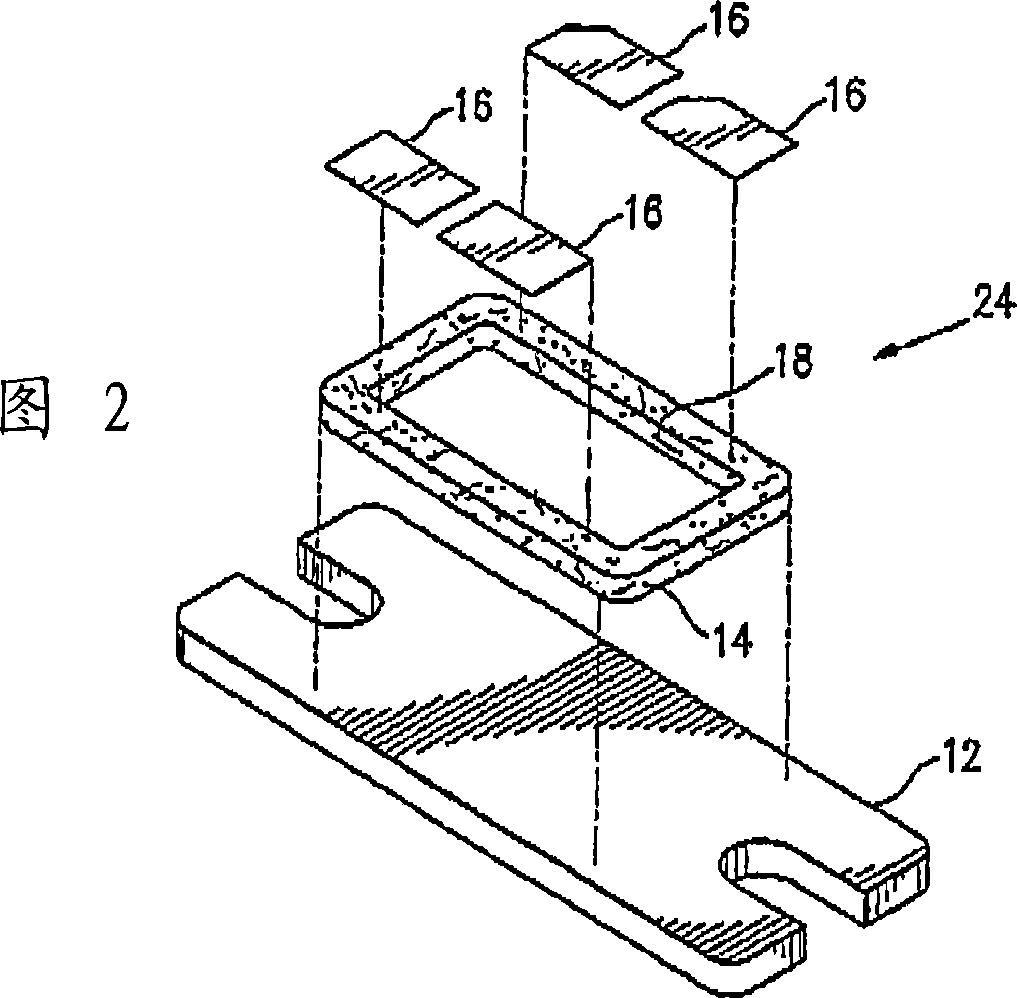

[0025] FIG. 2 is an exploded view of several components of the semiconductor package shown in FIG. 1 showing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com