Paster type light emitting type and process for manufacturing the same

A light-emitting diode and patch-type technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of inability to realize LED bare chip series connection, limit LED application, easy short circuit, etc., and reach the rated voltage High, loss-saving, simple connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

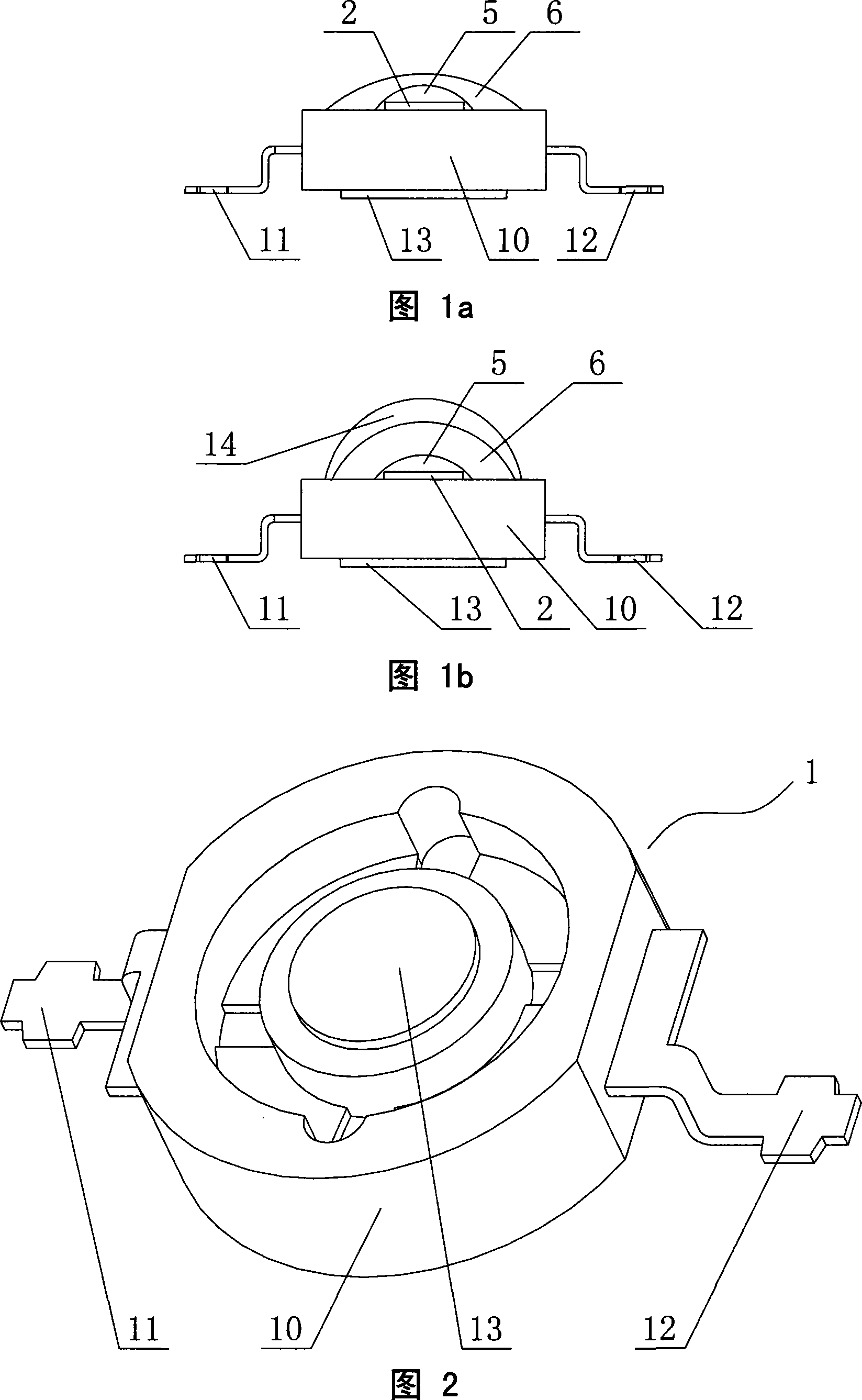

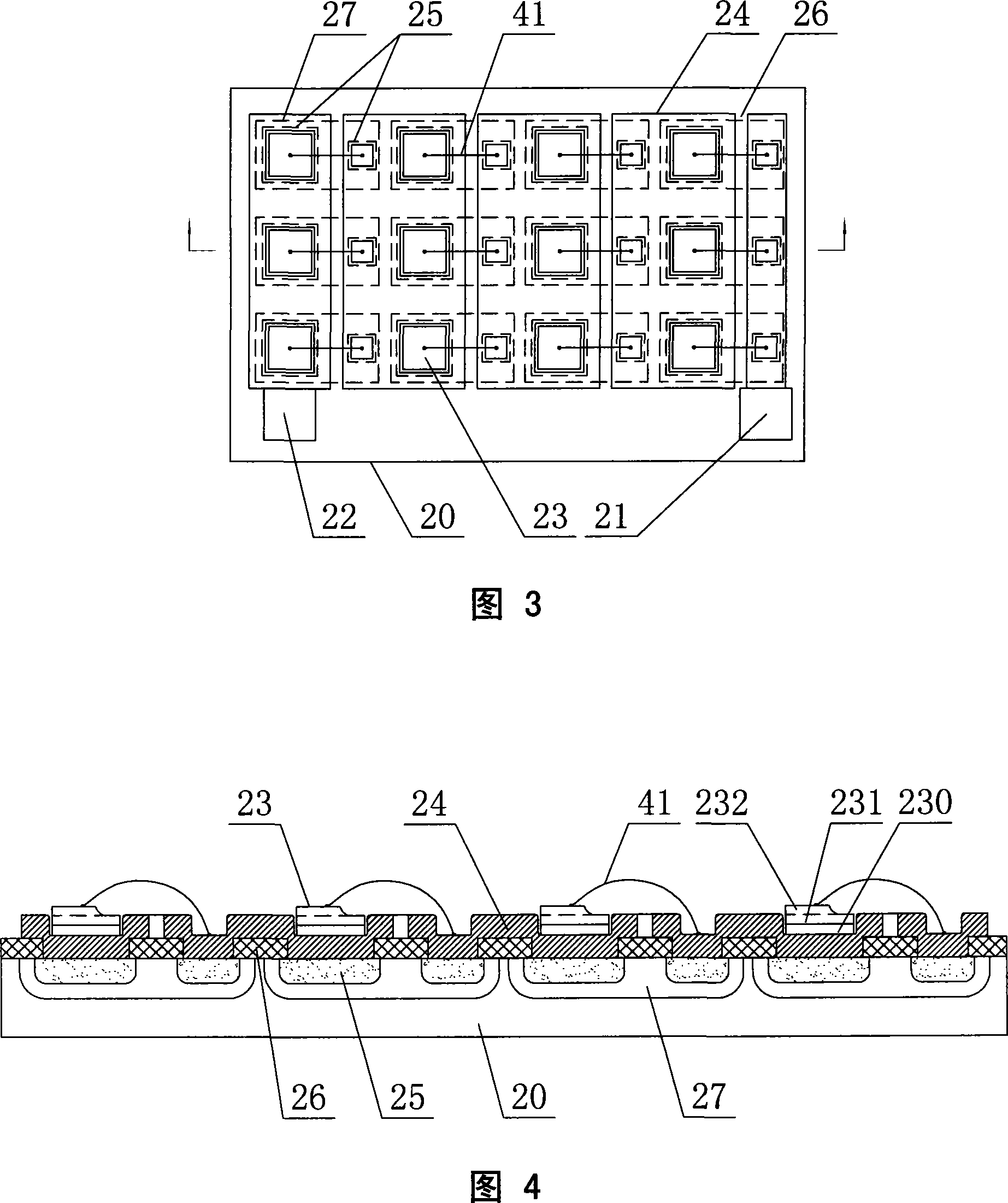

[0037]As shown in Fig. 1a, Fig. 2, Fig. 3, and Fig. 4, the patch type light-emitting diode of this embodiment includes a bracket 1, an LED chip 2, a phosphor powder 5 covering the LED chip 2, and a protective glue 6. The protective glue 6 is made of silica gel or resin, and the bracket 1 includes a housing 10, two pins 11, 12, and a cooling column 13. The housing 10 is made of insulating material, and the cooling column 13 is embedded in the shell. body 10 and penetrates the casing 10 up and down. The LED chip 2 is a positive-mounted LED integrated chip, including a silicon substrate 20, an anode contact 21, a cathode contact 22 and 12 LED bare chips 23, the silicon substrate 20 is fixed on the heat dissipation column 13, and the anode The contact 21 and the cathode contact 22 are respectively connected to the two pins 11 and 12 through metal leads. The LED bare chips 23 are connected in parallel every three to form a group, and then the four groups are connected in series. I...

Embodiment 2

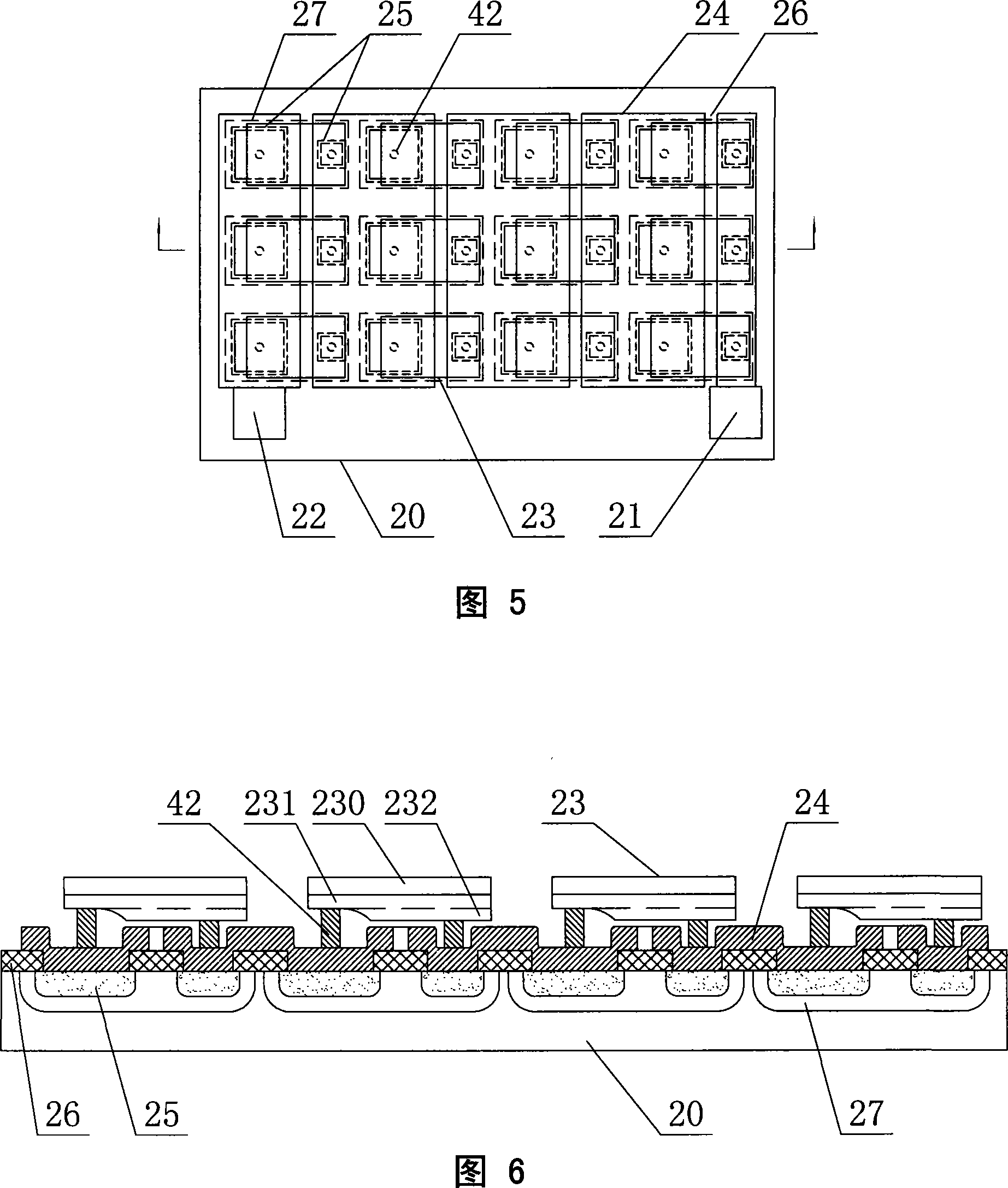

[0048] As shown in Figure 5 and Figure 6, the difference between this embodiment and Embodiment 1 is that the LED chip 2 of the chip-type light-emitting diode of this embodiment is a flip-chip LED integrated chip, and the P-type epitaxial layer 232 . The N-type epitaxial layer 231 is respectively flip-chip soldered on the metal layer 24 through solder balls 42 , and the solder balls 42 are gold ball plugs, and of course, may also be copper ball plugs or tin balls.

[0049] The remaining features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0051] As shown in Fig. 7 and Fig. 8, the difference between the present embodiment and the first embodiment is that the substrate 230 of the patch type light-emitting diode of the present embodiment is aluminum oxide (Al 2 o 3 ) substrate, that is, the LED bare chip 23 is a two-electrode chip, the substrate 230 is welded or pasted on the metal layer 24, and the P-type epitaxial layer 232 and the N-type epitaxial layer 231 pass through the The metal wires 43 , 45 are welded on the adjacent metal layers 24 .

[0052] The remaining features of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com