Bee venom refining process

A purification method and technology for bee venom, which are applied to medical preparations containing active ingredients, pharmaceutical formulas, unknown raw materials, etc., can solve the problems of complicated purification and purification process, limited bee venom, and refined products can not meet application requirements, etc. scientifically sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

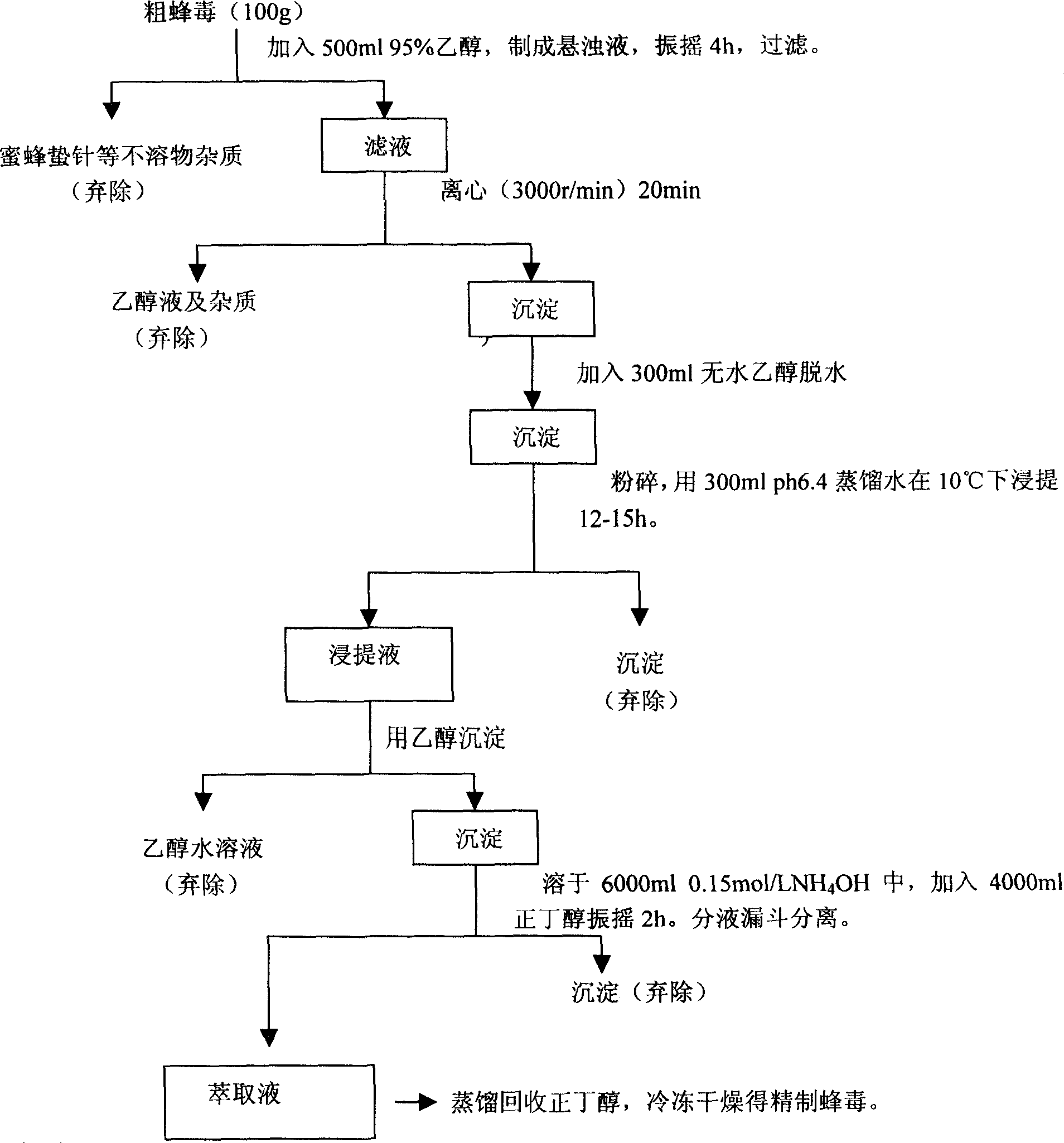

[0011] Take 100g of crude bee venom, add 500ml of 95% ethanol to make a suspension, shake for 4 hours, filter to remove insoluble impurities such as bee sting needles; remove the liquid phase after the filtrate is centrifuged (3000r / min) for 20min, and add 300ml of absolute ethanol to the precipitate Dehydrate, then extract the proposed precipitate with 300ml of PH=6.4 distilled water at 10±2°C for 12 to 15 hours, discard the precipitate, and precipitate the extract with ethanol to remove the aqueous ethanol solution; add 6000ml of 0.15 molar hydrogen to the precipitate Dissolve in ammonium and 4000ml n-butanol solution, shake for 2 hours to separate the liquid from the solid, discard the precipitate, distill the extract to recover n-butanol, freeze-dry the concentrate to obtain refined bee venom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com