Optimization method for process pressure of resin base composite equal thick laminate hot-press technology

A composite material and process pressure technology, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of high manufacturing cost, poor controllability of parts quality, cost of capital and time, and reduce manufacturing cost , Shorten the development cycle and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

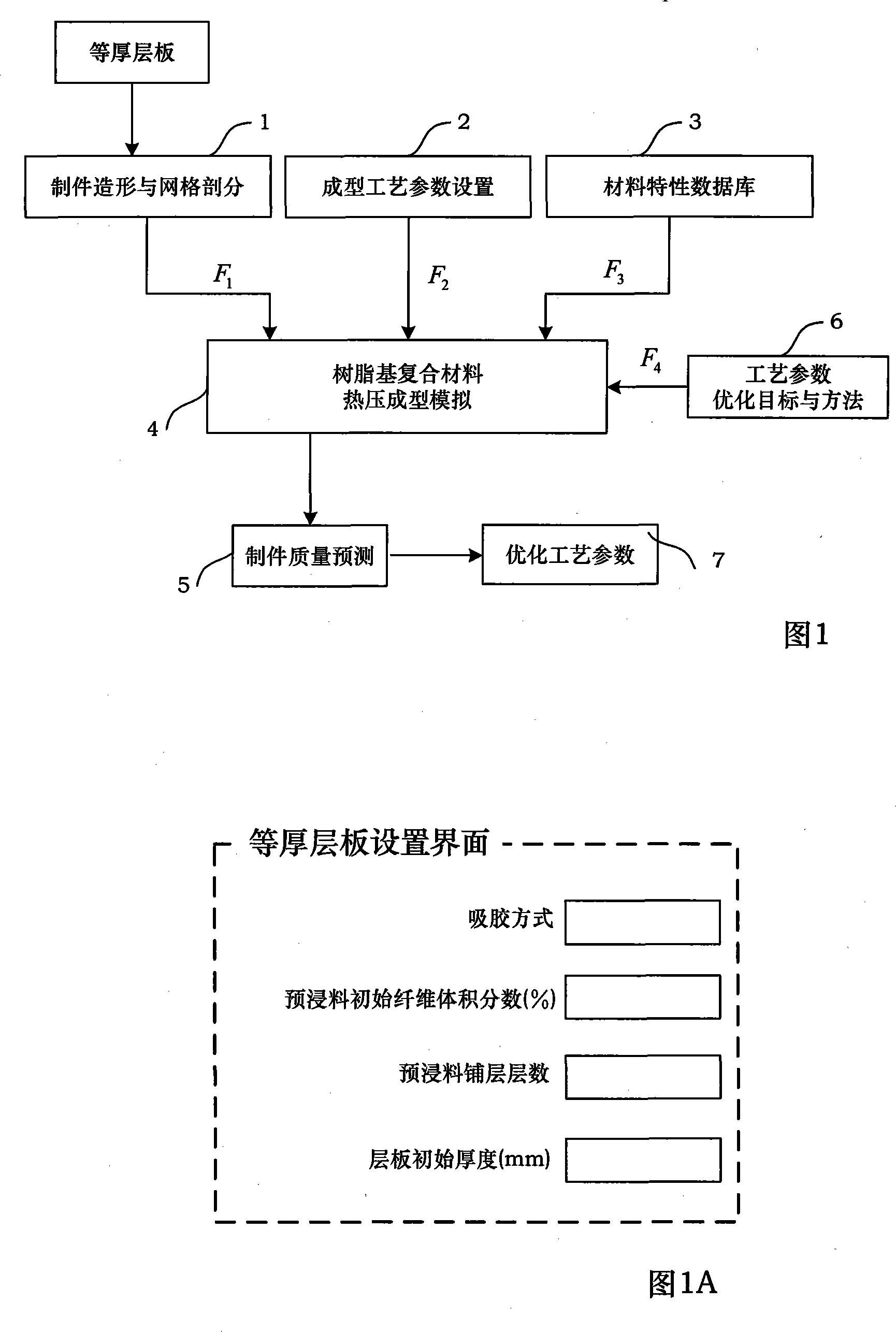

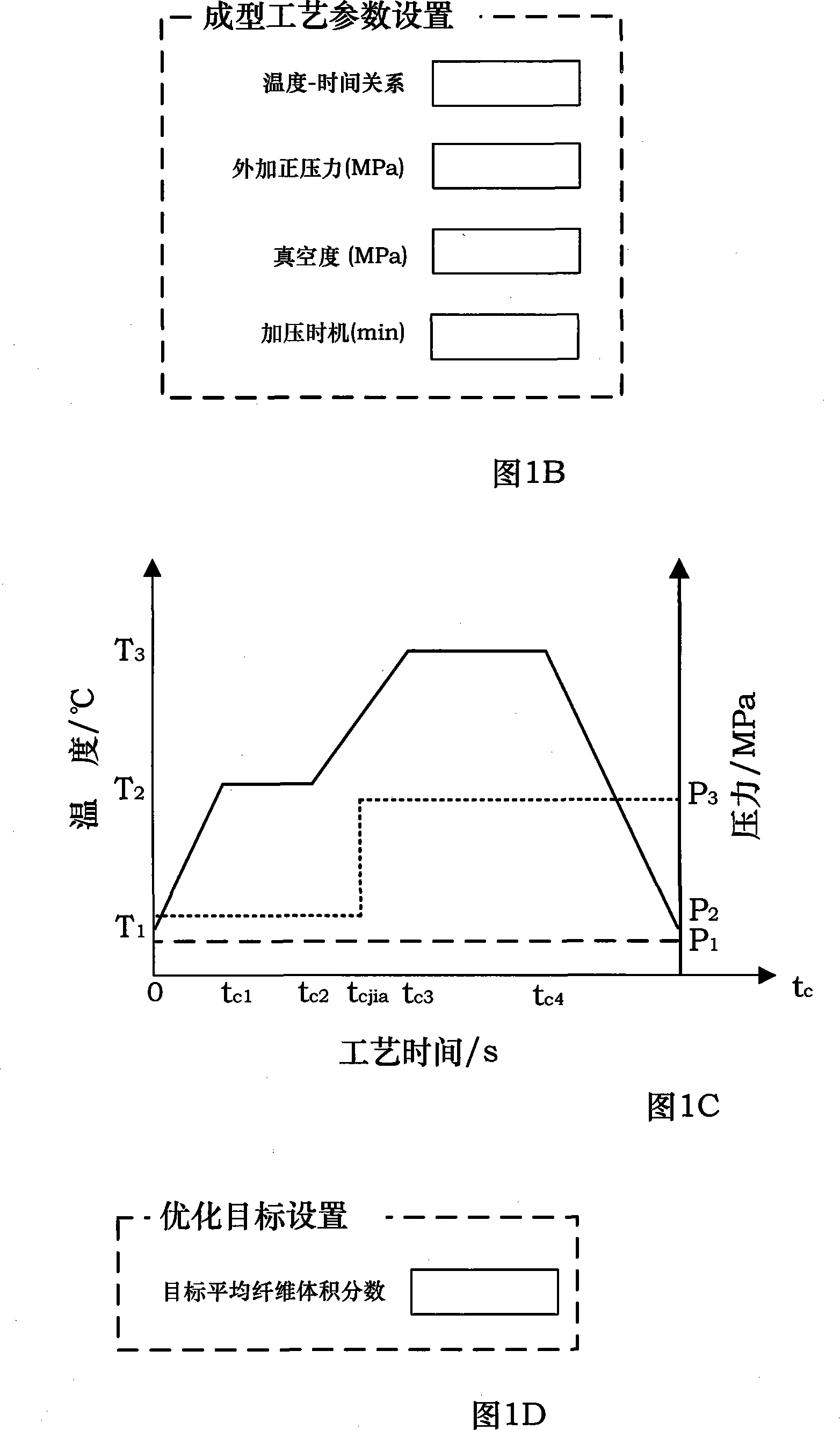

Method used

Image

Examples

Embodiment 1

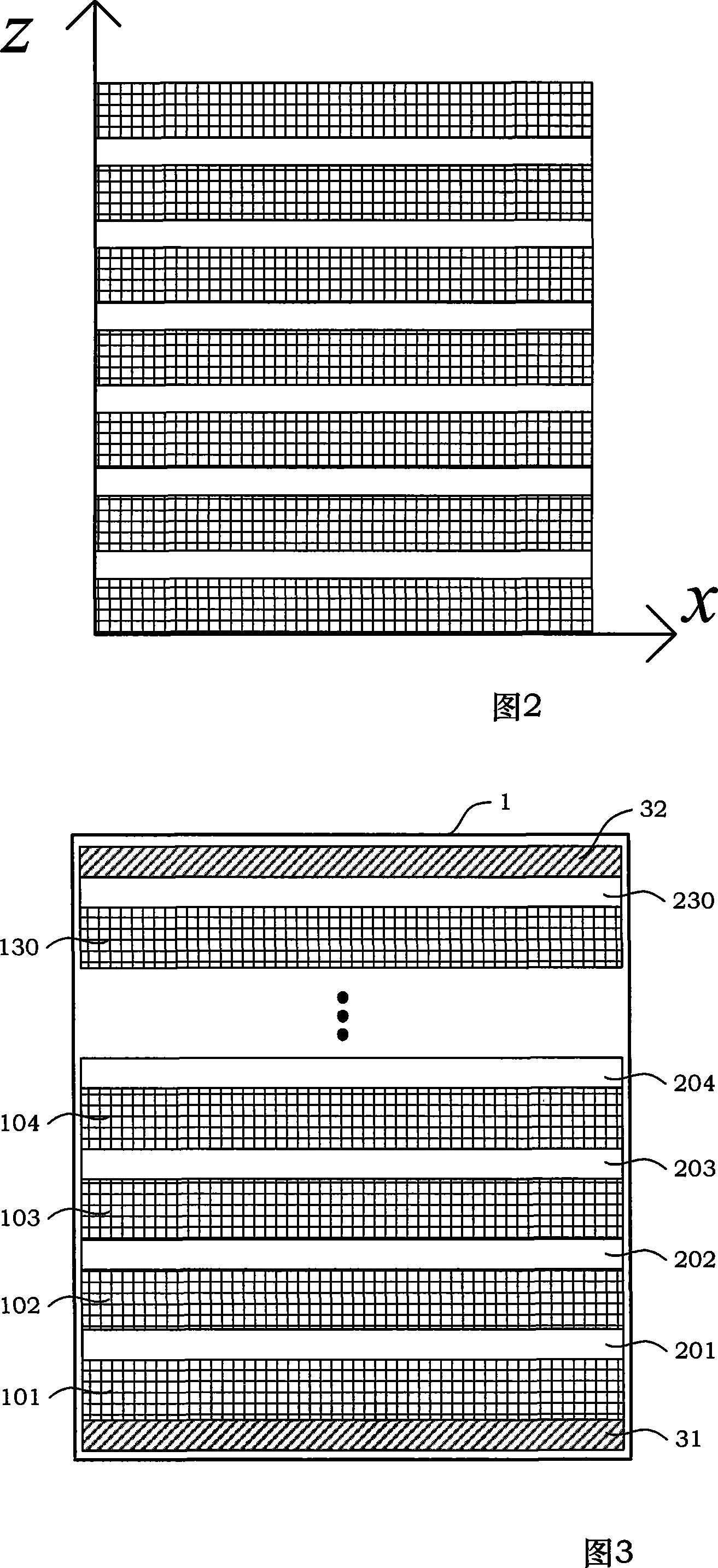

[0081] Example 1: The process pressure is optimized for 30-layer T700SC carbon fiber / epoxy 5228 resin and other thick laminates in one direction.

[0082] The structure of Example 1 is shown in Figure 3. In the mold 1, there are bottom-absorbing paper 31, A-layer fiber 101, A-layer resin 201, B-layer fiber 102, B-layer resin 202, and C-layer fiber. 103 , C layer resin 203 , D layer fiber 104 , D layer resin 204 , F layer fiber 130 , F layer resin 230 , and blotter paper 32 . This is a common layup system of "prepreg layup layers" (see Figure 1A), but the T700SC carbon fiber / epoxy 5228 resin material itself is a combination of fibers and resins. A schematic diagram of the structure is shown.

[0083]Step 1: At process pressure P c (0.1c Fi = min ( V f ‾ - V fg ‾ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com