Phosphor powder in use for light emitting diode (LED), and preparation method

A technology of light-emitting diodes and phosphors, applied in the field of phosphors, can solve the problems of large particle size distribution, reduced luminous efficiency, large sample particles, etc., and achieve the effects of small particle size, high luminous brightness, and strong excitation and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

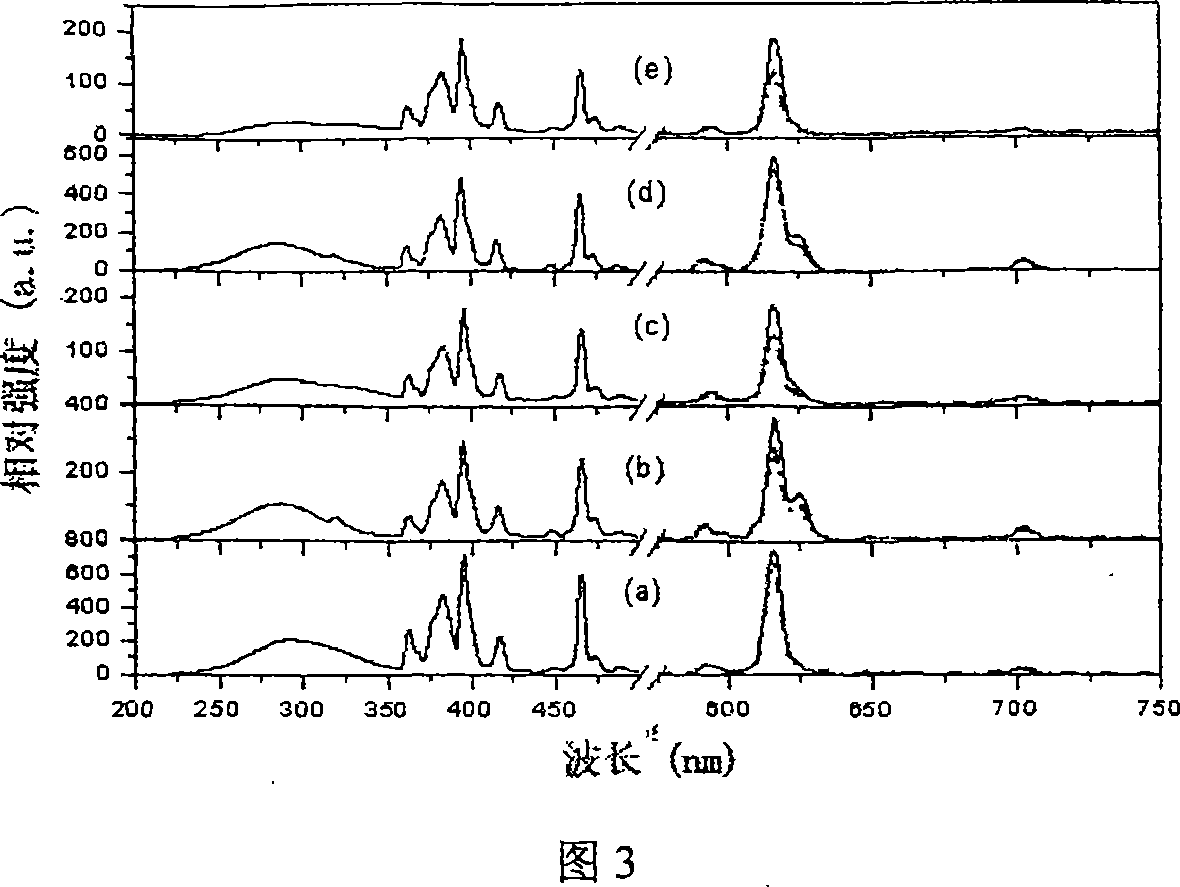

[0021] A molybdate red phosphor powder, which is a solid solution R 2-x-y Eu x A y (MoO 4 ) 3 , where R is La, x=0.8, y=0 (that is, without A), the solid solution can be expressed as La 1.2 Eu 0.8 (MoO 4 ) 3 . Weigh La 2 o 3 0.1278g, Eu 2 o 3 0.0893g, heat and dissolve with 40% hydrochloric acid (volume ratio), continue heating for a period of time to remove excess hydrochloric acid on the electric furnace, add 0.9567 grams of citric acid, (NH 4 ) 6 Mo 7 o 24 4H 2 O0.3449g, ultrasonically dispersed to make a transparent solution, with NH 3 ·H 2 O to adjust the pH to ≈7.5, keep it in an oven at 60°C for 72 hours, then raise the temperature to 240°C and keep it dry for 12 hours to obtain a black dry glue. Then the black dry glue is slightly baked on the electric furnace to make it carbonized and pre-fired in a high-temperature furnace at 600°C for 1h, and then the sample is calcined at 700°C and 900°C for 3h to obtain the desired red phosphor, and the powder di...

example 2

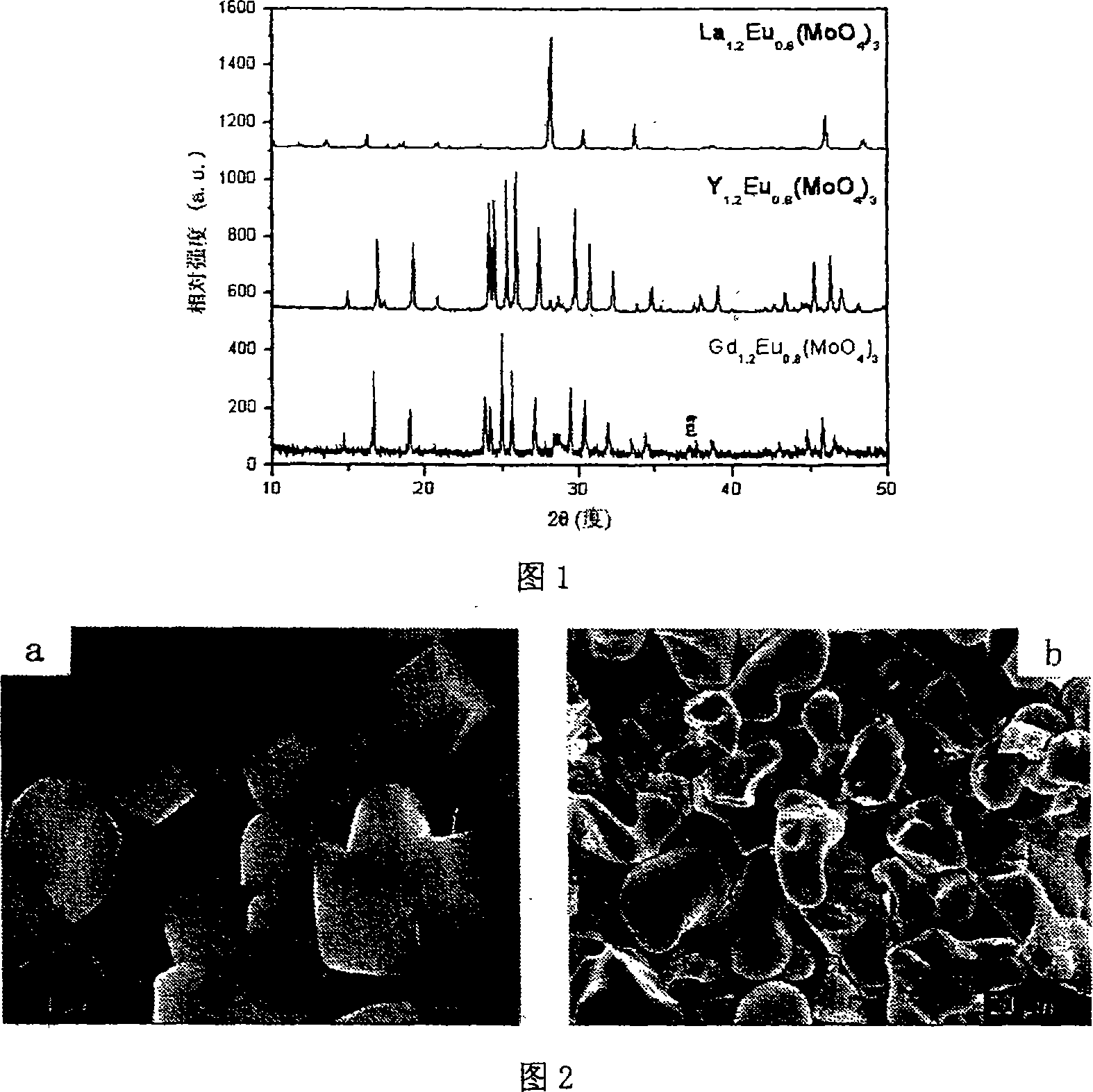

[0024] A molybdate red phosphor powder, which is a solid solution R 2-x-y Eu x A y (MoO 4 ) 3 , where R is Gd, x=0.8, y=0 (that is, without A), the solid solution can be expressed as Gd 1.2 Eu 0.8 (MoO 4 ) 3 . Measure 0.02mol / L of Eu(NO 3 ) 3 Solution 26ml, 0.01mol / L Gd(NO 3 ) 3 Solution 78ml, add citric acid 0.9343 grams, (NH 4 ) 6 Mo 7 o 24 4H 2 O0.3366g, ultrasonically dispersed to make a transparent solution, with NH 3 ·H 2 O to adjust the pH to ≈8, keep it in an oven at 90°C for 24 hours, then raise the temperature to 120°C and keep it dry for 24 hours to obtain a black dry glue. Then the black dry glue is slightly baked on the electric furnace to make it carbonized and pre-fired in a high-temperature furnace at 450°C for 5 hours, and then the sample is calcined at 900°C for 3 hours to obtain the required red phosphor. The phosphor is shown in Figure 1 The XRD pattern at 900°C, the particle size and morphology were observed by scanning electron microsco...

example 3

[0026] A molybdate red phosphor powder, which is a solid solution R 2-x-y Eu x A y (MoO 4 ) 3 , where R is Gd, x=1.2, y=0 (that is, without A), the solid solution can be expressed as Gd 0.8 Eu 1.2 (MoO 4 ) 3 . Measure 0.02mol / L of Eu(NO 3 ) 3 Solution 39ml, 0.01mol / L of Gd(NO 3 ) 3 Solution 52ml, add citric acid 0.9343 grams, (NH 4 ) 6 Mo 7 o 24 4H 2 O0.3366g, ultrasonically dispersed to make a transparent solution, with NH 3 ·H 2 O to adjust the pH to ≈8, keep it in an oven at 60°C for two days, heat it up to 100°C and dry it for 72 hours to obtain a black dry glue. Then the black dry glue is slightly baked on the electric furnace to make it carbonized and pre-fired in a high-temperature furnace at 500°C for 3h, and then the samples are calcined at 900°C and 800°C for 3h to obtain the required red phosphors, and their fluorescence spectra They are shown in Figure 3(d) and (e) respectively. It can be seen from the figure that their fluorescence spectra are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com